Winding machine for textile

A winding machine and body technology, applied in the textile field, can solve the problems of increasing labor and production costs, and achieve the effects of saving labor, strong versatility, and saving space and occupied area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

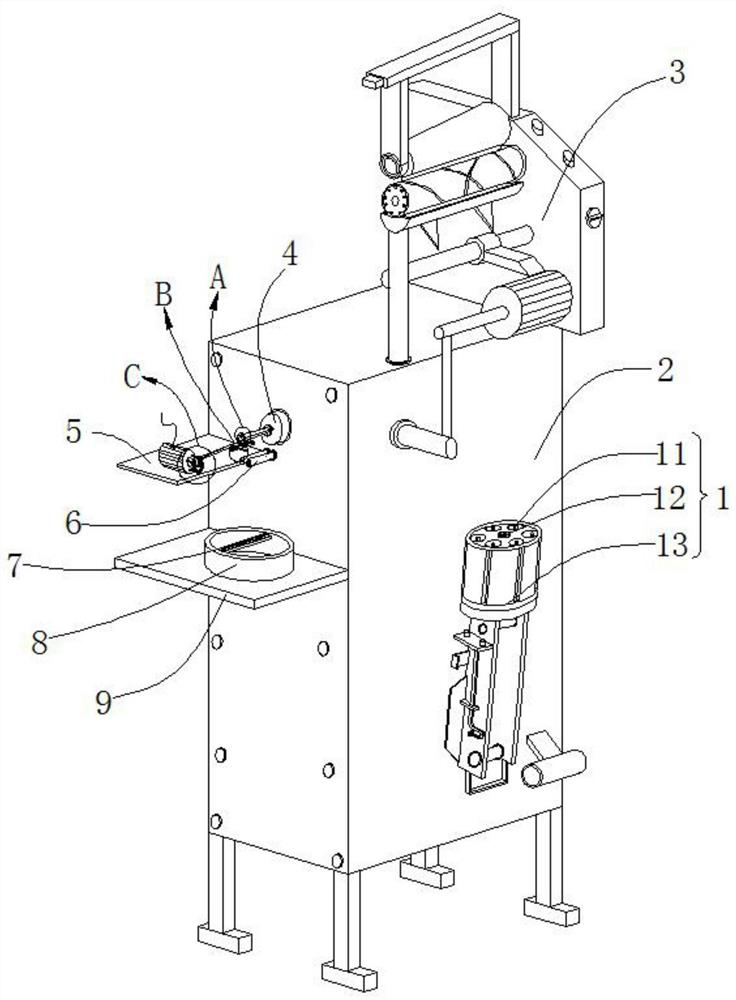

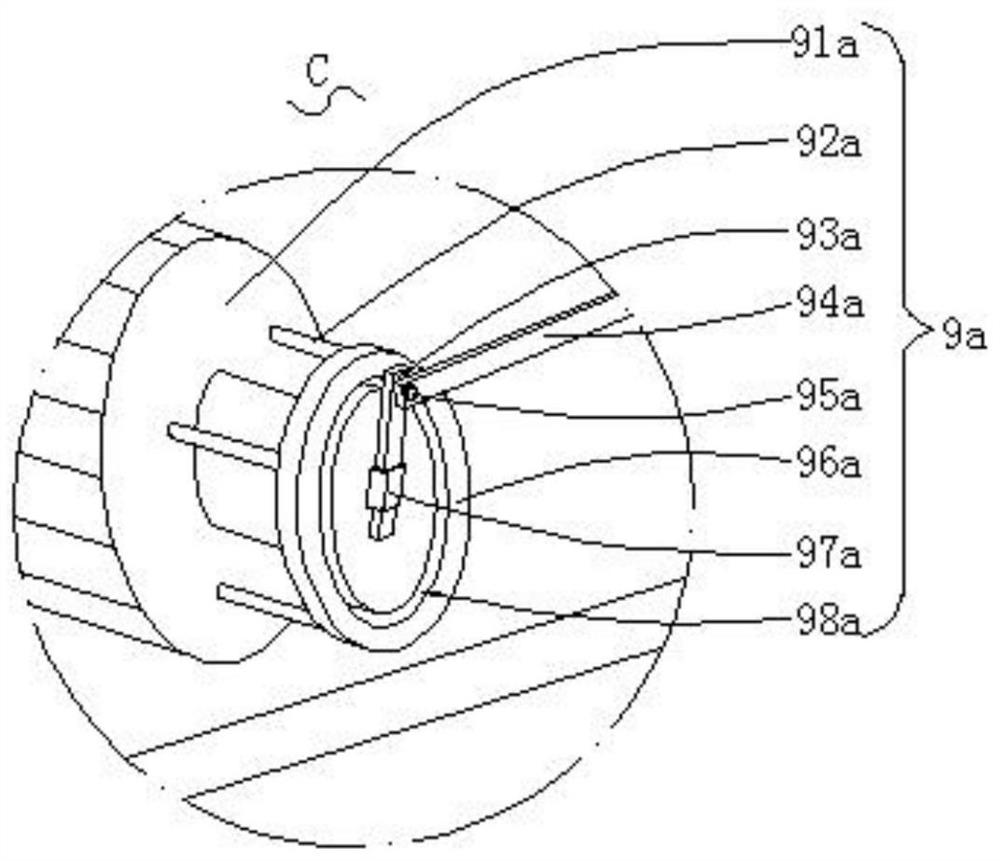

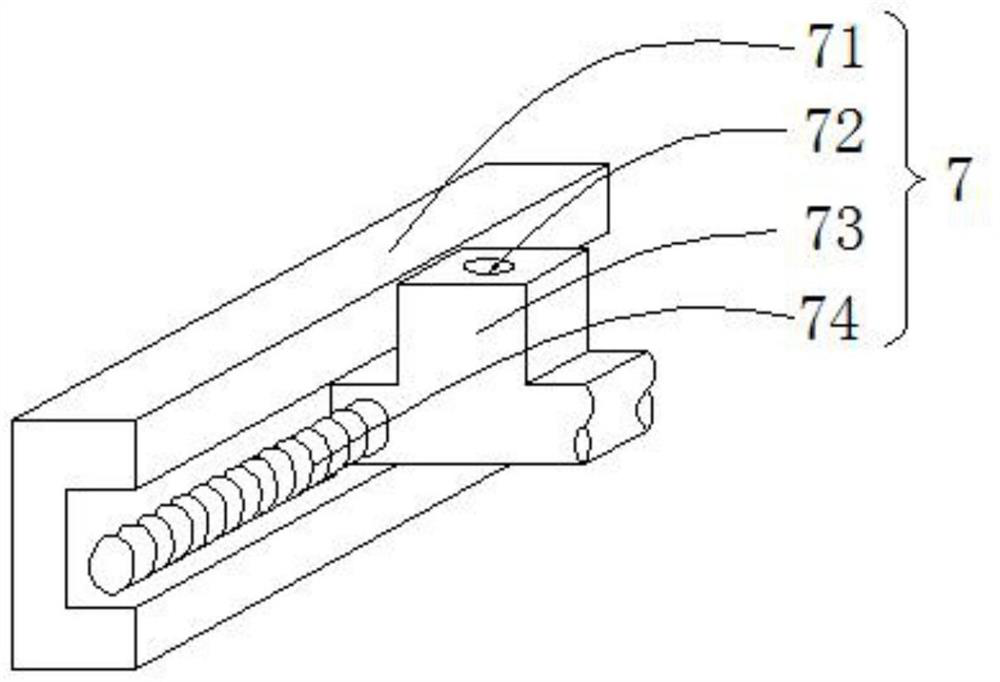

[0031] Such as figure 1As shown, a textile winding machine according to the present invention includes a pay-off mechanism 1, a housing 2, a body 3, a first motor 4, a first support plate 5, two No. 1 limit posts 6, a sliding Mechanism 7, wire box 8, second support plate 9, driving mechanism 9a, wire take-up mechanism 9b and wire pushing mechanism 9c; The side of the housing 2 is provided with the wire release mechanism 1 for placing and providing wire harnesses for the body 3, and half of the side wall of the housing 2 is vertically fixedly connected to the second support plate 9, and the second The surface of the support plate 9 is welded with the wire box 8 in a hollow cylindrical structure for placing the unwound wire harness. The inside of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com