Liquid medicine filling device with cleaning mechanism

A technology of liquid medicine and filling head, which is applied in the field of liquid medicine filling device with cleaning mechanism, can solve the problems of incomplete cleaning, buffer medicine residue, liquid medicine pollution, etc., and achieve good practical use and promotion value. , The structure improvement is simple and practical, and the cleaning efficiency is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

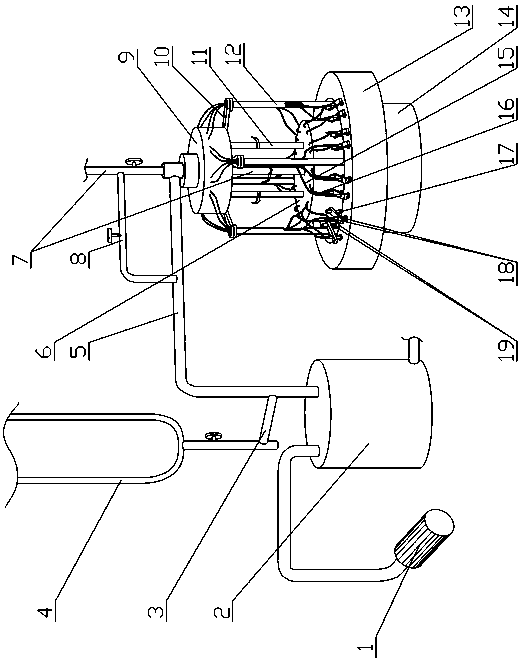

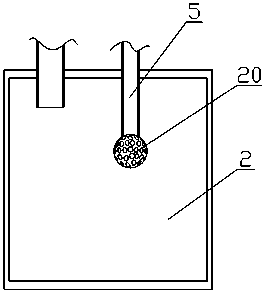

[0010] see figure 1 , figure 2 , the present invention is a liquid medicine filling device with a cleaning mechanism, comprising a rotating disk 14, on which a liquid medicine distributing tank 6 is arranged, the liquid medicine distributing tank communicates with the medicine feeding main pipe 7, and the medicine feeding main pipe is provided with a valve; Also be provided with several lifting columns 19 evenly along the circumference on the disk, the lifting columns rotate together with the rotating disk, and each lifting column is provided with a downwardly arranged liquid medicine filling head 18 through a fastened cross bar 17, and the liquid medicine filling head 18 is arranged on each lifting column. The filling head is communicated with the liquid medicine distribution tank through the medicine feeding hose 16, and an annular track 13 is also provided around the liquid medicine distribution tank, and a liquid medicine collection tank 9 is arranged above the liquid med...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap