Equipment for filling packages, especially bottles or cups, with food in liquid to pasty form

A packaging and paste-like technology, which is applied in the field of food filling and packaging, can solve the problems of maintenance, inspection and narrow specification change, and achieve the effect of reducing the risk of wrong operation and ensuring isolation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

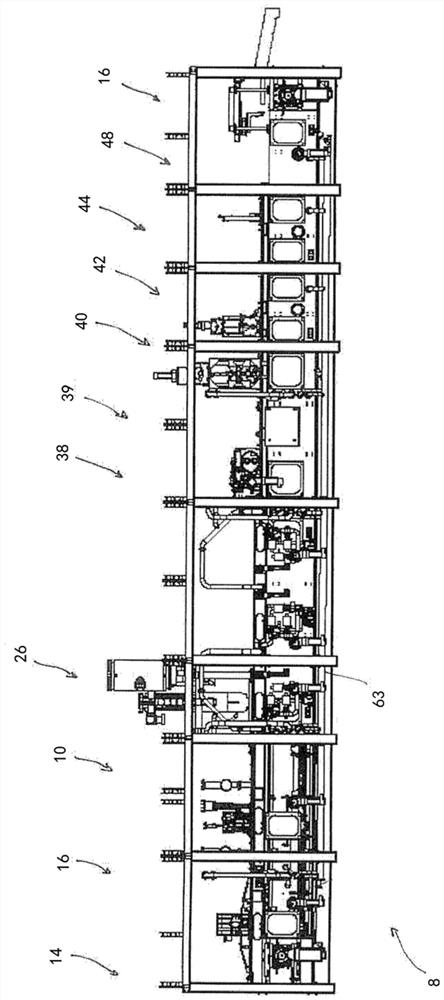

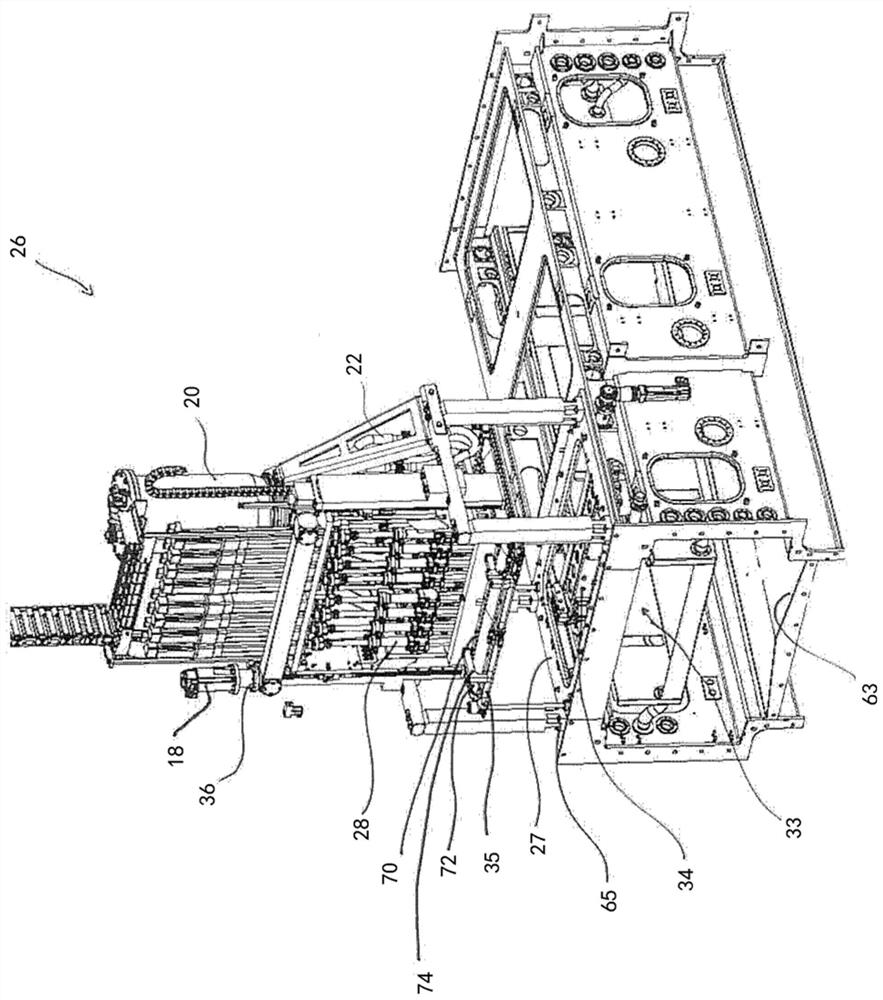

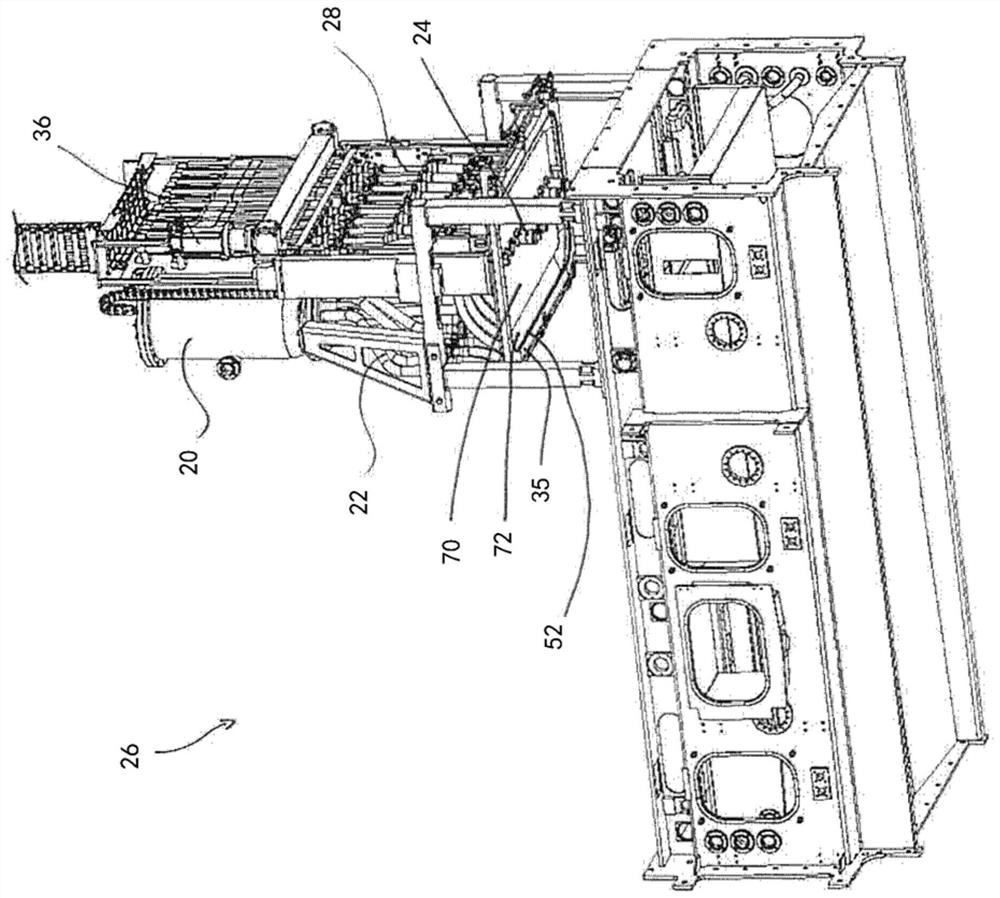

[0020] according to figure 1 The embodiment of the invention shows a filling machine 8 or a device 8 for filling packages, in particular bottles or cups, with liquid to pasty food and beverages. Packages such as cups, bottles or the like are supplied to the sterilization module 10 by a package supply device. This refers to already prefabricated packages. Here, for example, the stack of cups can be automatically inserted into the package supply device 14 . The pack carriers equipped with packs are moved by means of a conveyor system to different processing stations, such as pack supply, sterilisation, dosing, sealing, take-off etc. The conveyor system is implemented, for example, as an endless belt or chain. For this purpose, the conveying system includes, for example, a drive module 16 which includes, for example, a sprocket or a deflection device. A further drive module 16 for driving or deflecting the conveying system is arranged on the other side of the filling machine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com