High-durability regenerated concrete doped with waste iron wires and preparation method thereof

A recycled concrete and durability technology, which is applied in the preparation of high-durability recycled concrete and the field of high-durability recycled concrete, can solve the problems of low mechanical properties of recycled concrete, achieve good economic and environmental benefits, reduce costs, and reduce waste cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

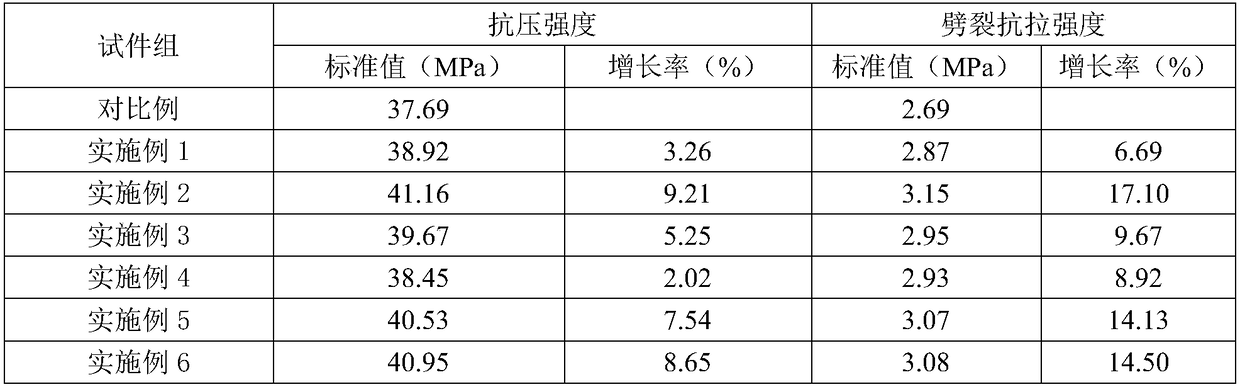

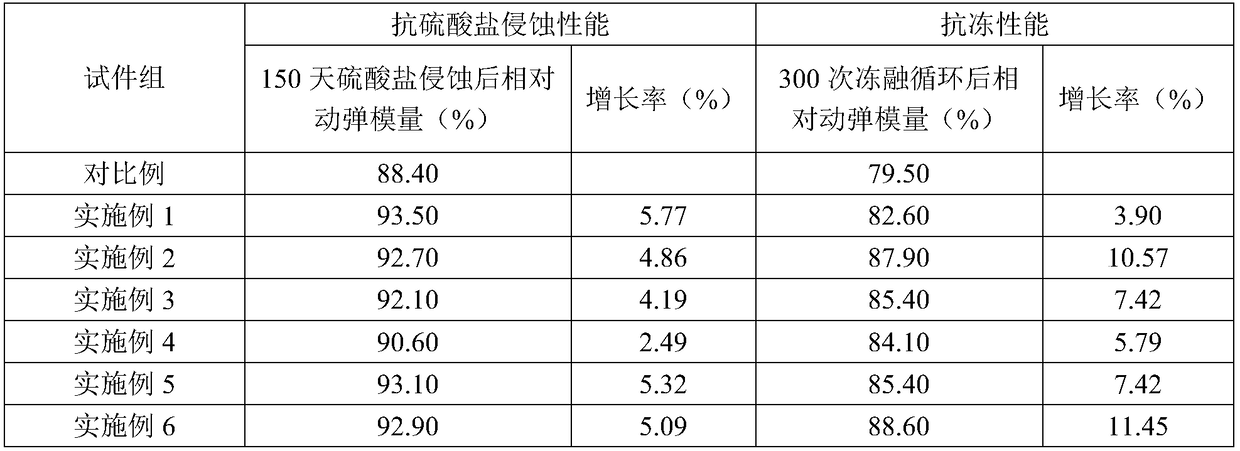

Examples

preparation example Construction

[0034] The present invention also provides a method for preparing the above-mentioned high-durability recycled concrete mixed with waste iron wire, comprising the following steps:

[0035] Step 1, prepare materials according to the ratio of the following raw materials,

[0036] Each cubic meter of high-durability recycled concrete consists of the following raw materials:

[0037] 180~200kg of water, 400~450kg of cement, 80~90kg of fly ash, 780~820kg of artificial sand, 1020~1100kg of recycled coarse aggregate, 2.6~5.8kg of water reducing agent, 52~87g of air entraining agent, 2.6~ of waste iron wire 4.35kg;

[0038] Step 2. Pour 50% of water, regenerated coarse aggregate, artificial sand and waste iron wire into the concrete mixer in sequence, stir for 15-20 seconds, and stir evenly to make the surface of the regenerated coarse aggregate moist;

[0039] Step 3. Pour the fly ash into the blender, stir for 15-20 seconds, and stir evenly;

[0040] Step 4, add cement, stir for ...

Embodiment 1

[0057]Crushing the waste concrete into recycled coarse aggregate, ensuring that the particle size of the waste coarse aggregate is 5-20mm; at the same time collecting a large number of different types of waste iron wire, and cutting it to a length of 2cm;

[0058] The high-durability recycled concrete mixed with waste iron wire comprises the following steps:

[0059] Step 1, prepare materials according to the ratio of the following raw materials,

[0060] Each cubic meter of high-durability recycled concrete consists of the following raw materials:

[0061] 190kg of water, 420kg of cement, 85kg of fly ash, 800kg of artificial sand, 1050kg of recycled coarse aggregate, 4kg of water reducing agent, 60g of air-entraining agent, and 3.5kg of waste iron wire;

[0062] Step 2. Pour 50% water, recycled coarse aggregate, artificial sand and waste iron wire into the concrete mixer in sequence, and stir for 15-20 seconds to make the surface of the recycled coarse aggregate wet;

[006...

Embodiment 2

[0068] Crushing the waste concrete into recycled coarse aggregate, ensuring that the particle size of the waste coarse aggregate is 5-20mm; at the same time collecting a large number of different types of waste iron wire, and cutting it to a length of 5cm;

[0069] The high-durability recycled concrete mixed with waste iron wire comprises the following steps:

[0070] Step 1, prepare materials according to the ratio of the following raw materials,

[0071] Each cubic meter of high-durability recycled concrete consists of the following raw materials:

[0072] 190kg of water, 420kg of cement, 85kg of fly ash, 800kg of artificial sand, 1050kg of recycled coarse aggregate, 4kg of water reducing agent, 60g of air-entraining agent, and 3.5kg of waste iron wire;

[0073] Step 2. Pour 50% water, recycled coarse aggregate, artificial sand and waste iron wire into the concrete mixer in sequence, and stir for 15-20 seconds to make the surface of the recycled coarse aggregate wet;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com