Silica gel supporter, supported catalyst and preparation method thereof

A supported catalyst and silica gel technology, applied in the field of supported catalysts, can solve the problem of insufficient catalytic activity, achieve low melt index, low bulk density, and reduce powder agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0020] The invention provides a method for preparing a silica gel carrier, the method comprising:

[0021] (1) Mix and contact water glass, polyol, n-butanol and inorganic acid, and use a ceramic membrane filter to filter and / or wash the mixture obtained after the contact to obtain a silica gel cake;

[0022] (2) Ball mill the silica gel cake obtained in step (1), and then perform spray drying to obtain a silica gel carrier.

[0023] According to the present invention, in step (1), the amount of water glass, polyol, n-butanol and inorganic acid can be conventionally selected in the field, for example, the amount of water glass, inorganic acid, n-butanol and polyol The weight ratio of the amount can be 3-6:0.5-4:0.5-1.5:1, preferably 3-6:1-3:1:1. The amount of the inorganic acid is such that the pH value of the mixed contact in step (1) is 2-4.

[0024] In the present invention, the water glass generally refers to an aqueous solution of sodium silicate, the concentration of which may ...

Example Embodiment

[0058] Example 1

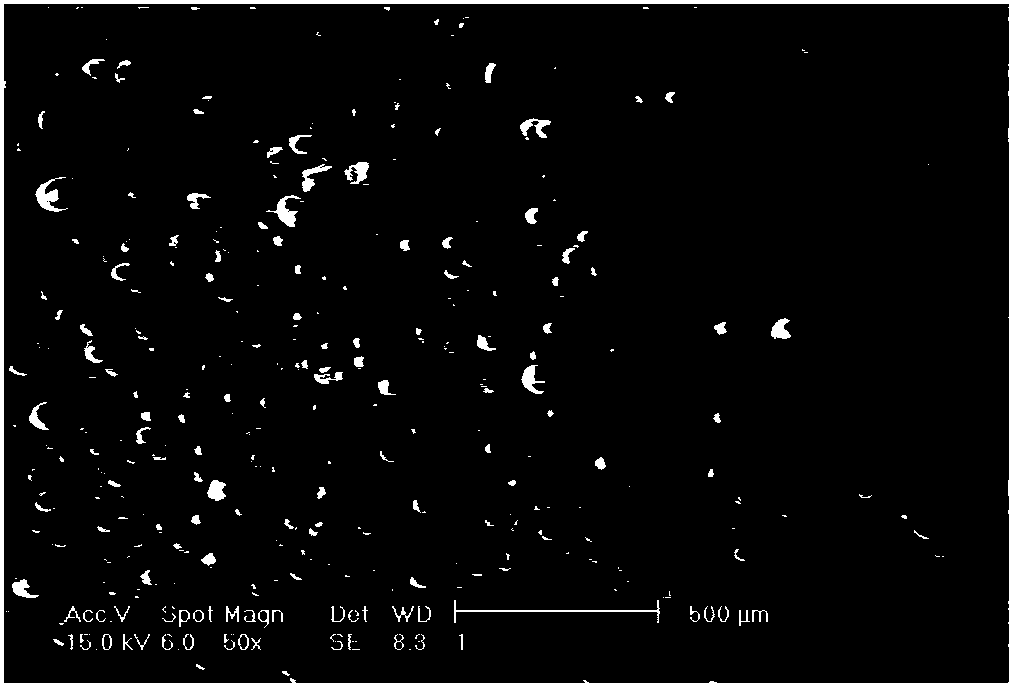

[0059] This example is used to illustrate the silica gel carrier and supported catalyst of the present invention and the preparation method thereof

[0060] (1) Preparation of silica gel carrier

[0061] The water glass with a concentration of 15% by weight, a sulfuric acid solution with a concentration of 12% by weight, n-butanol and glycerol in a weight ratio of 5:1:1:1 were mixed and contacted and reacted at 20°C for 1.5 hours, and then used The pH value of sulfuric acid with a concentration of 98% by weight is adjusted to 3, and then the obtained reaction material is suction filtered and washed with a ceramic membrane filter to a sodium ion content of 0.02% by weight to obtain a silica gel cake. Among them, the membrane module operating pressure is 3.3bar, the circulation side membrane inlet pressure is 4bar, the circulation side membrane outlet pressure is 2.5bar, the circulation side membrane surface flow rate is 4m / s, the permeate side pressure is 0.3bar, a...

Example Embodiment

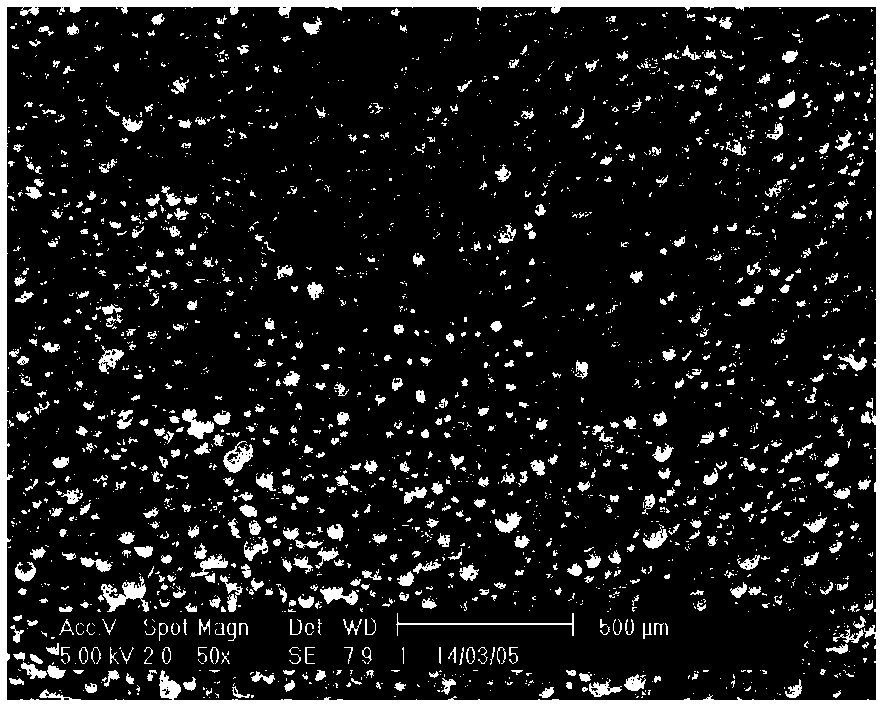

[0073] Example 2

[0074] This example is used to illustrate the silica gel carrier and supported catalyst of the present invention and the preparation method thereof

[0075] (1) Preparation of silica gel carrier

[0076] The water glass with a concentration of 15% by weight, a sulfuric acid solution with a concentration of 12% by weight, n-butanol and glycerol in a weight ratio of 6:3:1:1 were mixed and contacted for reaction at 60°C for 3 hours, and then used The pH value of sulfuric acid with a concentration of 98% by weight is adjusted to 3, and then the obtained reaction material is suction filtered and washed with a ceramic membrane filter to a sodium ion content of 0.02% by weight to obtain a silica gel cake. Among them, the membrane module operating pressure is 3bar, the circulation side membrane inlet pressure is 3.5bar, the circulation side membrane outlet pressure is 2.5bar, the circulation side membrane surface flow rate is 4.5m / s, the permeate side pressure is 0.4bar, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap