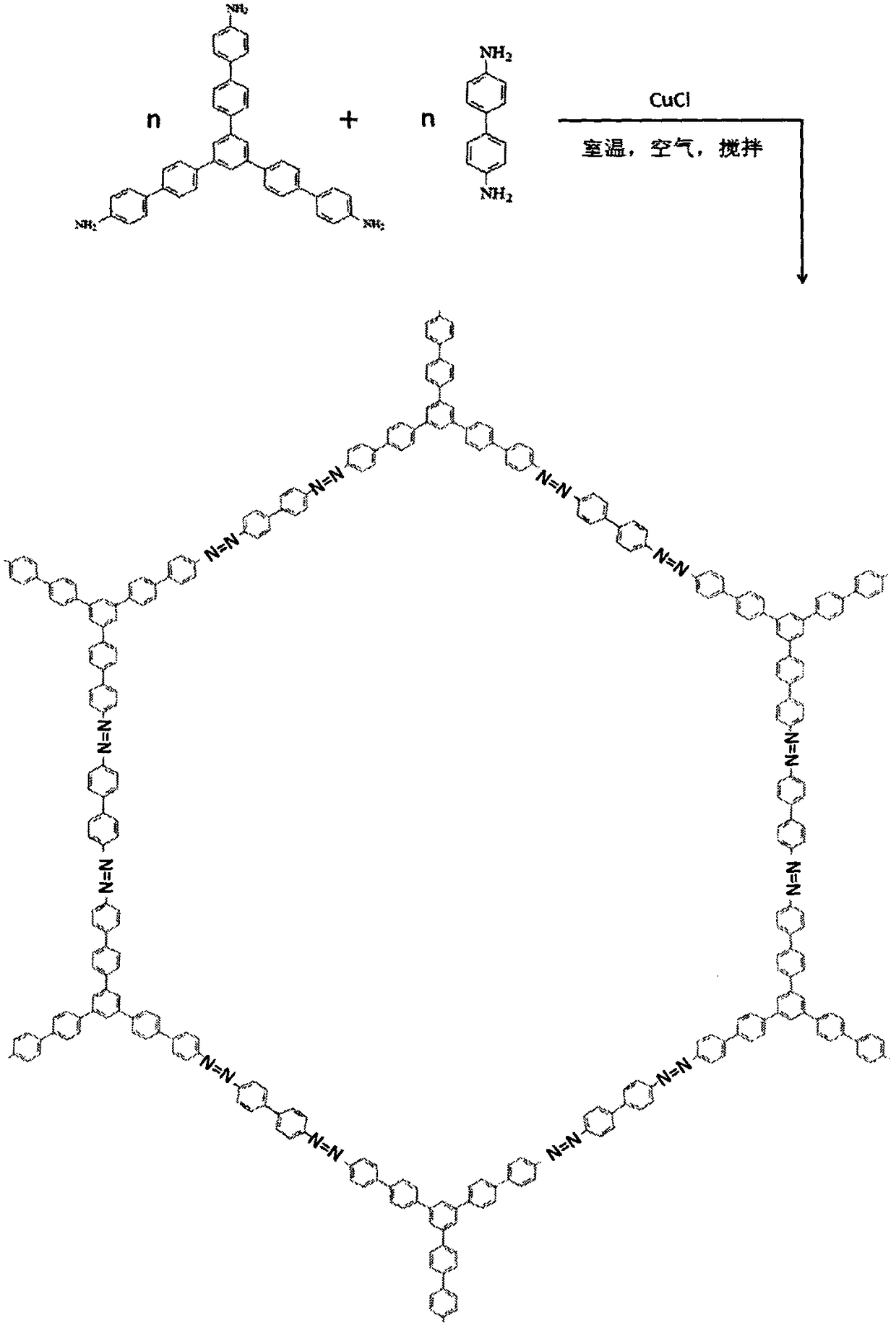

Preparation method of large-aperture organic covalent framework material

A framework material and large pore size technology, used in the preparation of large pore size organic covalent framework materials, can solve the problems of restricting the development of new structures and new materials, limited reaction types, etc., and achieve easy industrialized mass production, high chemical stability and Thermal stability, effect of large pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Weigh 0.8524g of copper chloride dihydrate, place it in a 50mL polytetrafluoroethylene-lined autoclave, add 25mL of ethanol, mix well, and cover the kettle tightly.

[0021] (2) Put the autoclave in a muffle furnace and react at 160°C for 24h. Cool to room temperature, filter under reduced pressure, and dry the product in vacuum at 50°C for 12 hours. Store in a dark place under a nitrogen protection atmosphere to obtain cuprous chloride nanocrystals with a diameter of 2-10 nm.

[0022] (3) 10 mg of cuprous chloride crystal powder, 10 mg of benzidine and 30 mg of 1,3,5-tris[4-amino(1,1-biphenyl-4-yl)]benzene were dissolved in 5.0 mL of acetonitrile, Stir at room temperature for 10 h.

[0023] (4) The reaction mixture was taken out, washed with 25% ammonia water, water and acetone respectively, and dried and stored.

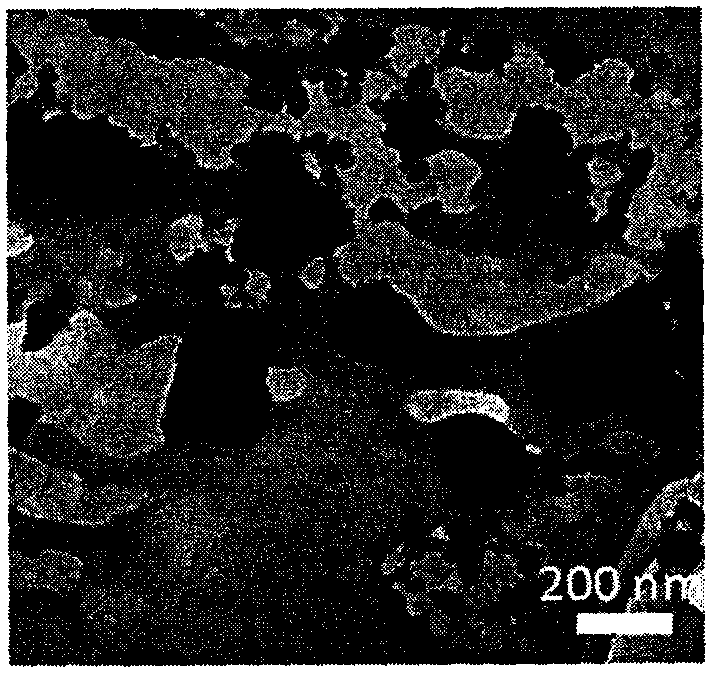

[0024] figure 1 It includes a schematic diagram of the reaction process and a schematic structure of the large-aperture organic covalent framework m...

Embodiment 2

[0027] (1) Weigh 0.8524g of copper chloride dihydrate, place it in a 50mL polytetrafluoroethylene-lined autoclave, add 25mL of ethanol, mix well, and cover the kettle tightly.

[0028] (2) Put the autoclave in a muffle furnace and react at 160°C for 24h. Cool to room temperature, filter under reduced pressure, and dry the product in vacuum at 50°C for 12 hours. Store in a dark place under a nitrogen protection atmosphere to obtain cuprous chloride nanocrystals with a diameter of 2-10 nm.

[0029] (3) 20mg of cuprous chloride crystal powder, 10mg of benzidine and 30mg of 1,3,5-tris[4-amino(1,1-biphenyl-4-yl)]benzene were dissolved in 5.0mL of acetonitrile, Stir at room temperature for 10 h.

[0030] (4) The reaction mixture was taken out, washed with 25% ammonia water, water and acetone respectively, and dried and stored.

Embodiment 3

[0032] (1) Weigh 0.8524g of copper chloride dihydrate, place it in a 50mL polytetrafluoroethylene-lined autoclave, add 25mL of ethanol, mix well, and cover the kettle tightly.

[0033] (2) Put the autoclave in a muffle furnace and react at 160°C for 24h. Cool to room temperature, filter under reduced pressure, and dry the product in vacuum at 50°C for 12 hours. Store in a dark place under a nitrogen protection atmosphere to obtain cuprous chloride nanocrystals with a diameter of 2-10 nm.

[0034] (3) 10 mg of cuprous chloride crystal powder, 10 mg of benzidine and 30 mg of 1,3,5-tris[4-amino(1,1-biphenyl-4-yl)]benzene were dissolved in 5.0 mL of acetonitrile, Stir at room temperature for 48h.

[0035] (4) The reaction mixture was taken out, washed with 25% ammonia water, water and acetone respectively, and dried and stored.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap