A large-area thick film for gan neutron detectors 6 Preparation method of lif neutron conversion layer

A neutron detector, large-area technology, used in semiconductor detector measurement, coating, ion implantation plating, etc. problem, to achieve the effect of high neutron detection efficiency, high sensitivity and good crystal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

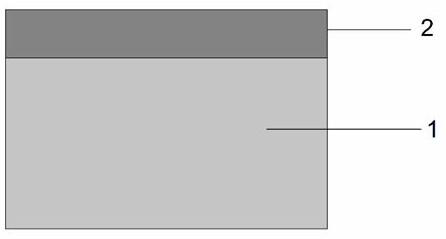

[0034] First, a GaN self-supporting substrate 1 with a thickness of 100 μm was placed in a 120-degree H 2 SO 4 :H 2 o 2 (5:1) Boil in the mixed solution for 5 minutes, then soak in the HCL:DI=3:1 mixed solution for 5 minutes to remove the oxides on the GaN surface; then use acetone, isopropanol, deionized GaN substrate Water was ultrasonically cleaned for 5 minutes each to remove organic and inorganic contamination on the GaN surface, and then dried with nitrogen gas with a purity of 99.999% ( figure 2 );

[0035] Secondly, put the cleaned GaN substrate into the electron beam evaporation equipment and evacuate to 8×10 -6 pa, deposit Au with a thickness of 1 μm on the front surface of the GaN substrate to form the front Au electrode 2 ( image 3 );

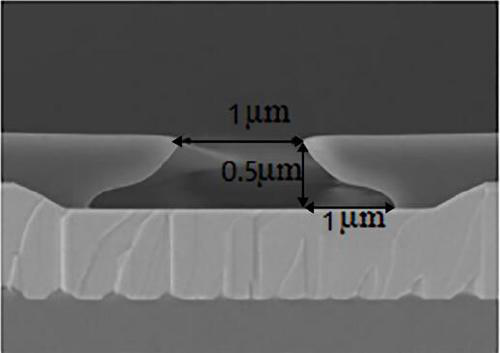

[0036]Subsequently, a layer of negative photoresist 3 ( Figure 4 ), the first rotation speed of the homogenizer is 500 rpm, and the time is 8 seconds; the second rotation speed is 2500 rpm, and the time is 20 seconds; then...

Embodiment 2

[0040] First, a GaN self-supporting substrate 1 with a thickness of 100 μm was placed in a 120-degree H 2 SO 4 :H 2 o 2 (5:1) Boil in the mixed solution for 5 minutes, then soak in the HCL:DI=3:1 mixed solution for 5 minutes to remove the oxides on the GaN surface; then use acetone, isopropanol, deionized GaN substrate Water was ultrasonically cleaned for 5 minutes each to remove organic and inorganic contamination on the GaN surface, and then dried with nitrogen gas with a purity of 99.999% ( figure 2 );

[0041] Secondly, put the cleaned GaN substrate into the electron beam evaporation equipment and evacuate to 8×10 -6 pa, deposit Au with a thickness of 0.8 μm on the front surface of the GaN substrate to form the front Au electrode 2 ( image 3 );

[0042] Subsequently, a layer of negative photoresist 3 ( Figure 4 ), the first speed of the homogenizer is 500 rpm for 8 seconds, the second speed is 3000 rpm for 20 seconds; then put it on a hot plate at 90°C for 90 sec...

Embodiment 3

[0046] First, a GaN self-supporting substrate 1 with a thickness of 100 μm was placed in a 120-degree H 2 SO 4 :H 2 o 2 (5:1) Boil in the mixed solution for 5 minutes, then soak in the HCL:DI=3:1 mixed solution for 5 minutes to remove the oxides on the GaN surface; then use acetone, isopropanol, deionized GaN substrate Water was ultrasonically cleaned for 5 minutes each to remove organic and inorganic contamination on the GaN surface, and then dried with nitrogen gas with a purity of 99.999% ( figure 2 );

[0047] Secondly, put the cleaned GaN substrate into the electron beam evaporation equipment and evacuate to 8×10 -6 pa, deposit Au with a thickness of 2 μm on the front surface of the GaN substrate to form the front Au electrode 2 ( image 3 );

[0048] Subsequently, a layer of negative photoresist 3 ( Figure 4 ), the first rotation speed of the homogenizer is 500 rpm, and the time is 8 seconds; the second rotation speed is 2000 rpm, and the time is 20 seconds; the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com