A kind of thermal decomposition preparation method of thin film

A thin film preparation and thermal decomposition technology, applied in metal material coating process, coating, gaseous chemical plating, etc., can solve the problems of increased equipment complexity, failure rate, expensive equipment, and high equipment requirements, and achieve significant technological progress , obvious substantive characteristics, the effect of improving the quality of film formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0024] A method for preparing a thin film by thermal decomposition, characterized in that it comprises the following steps:

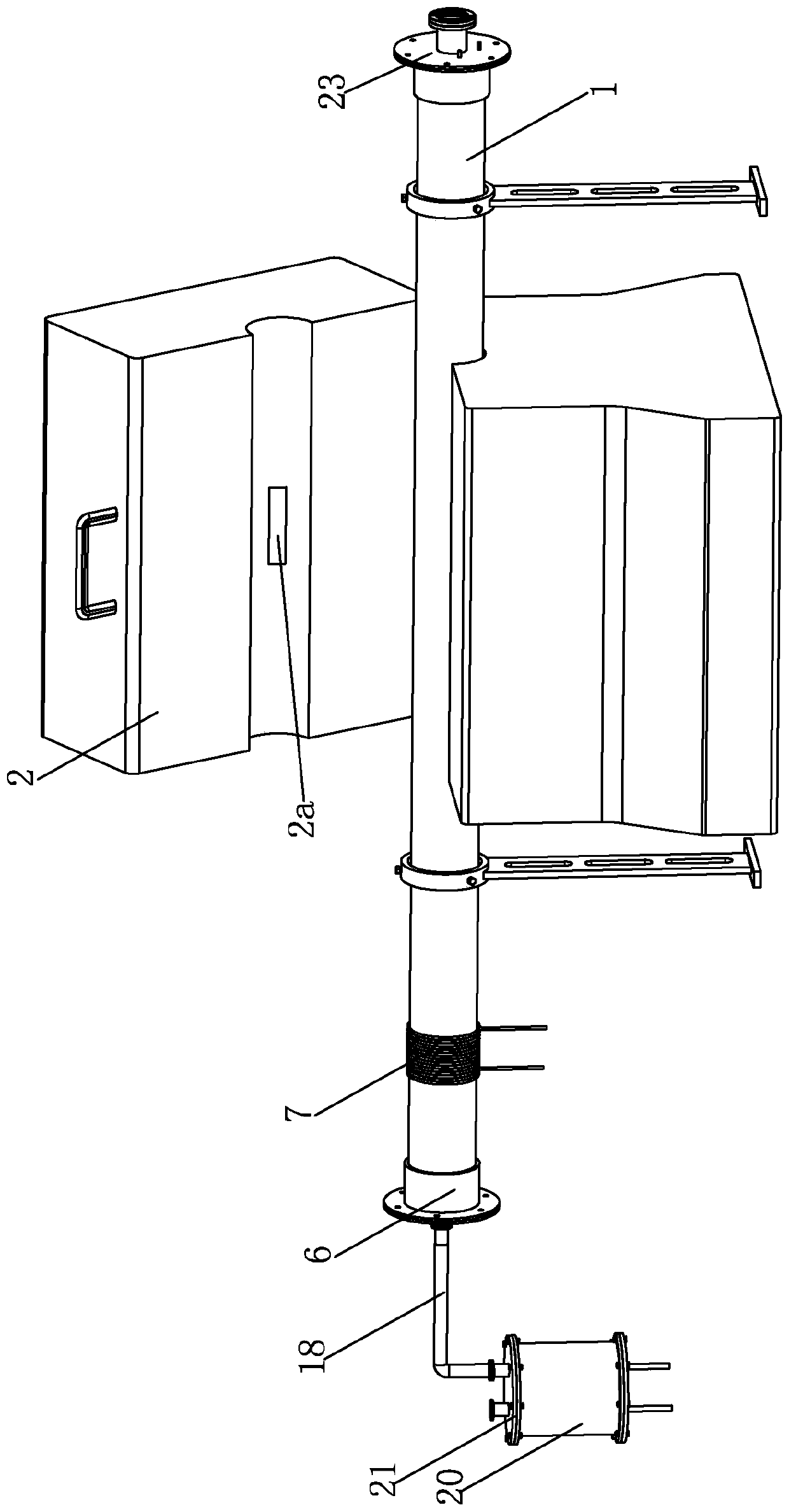

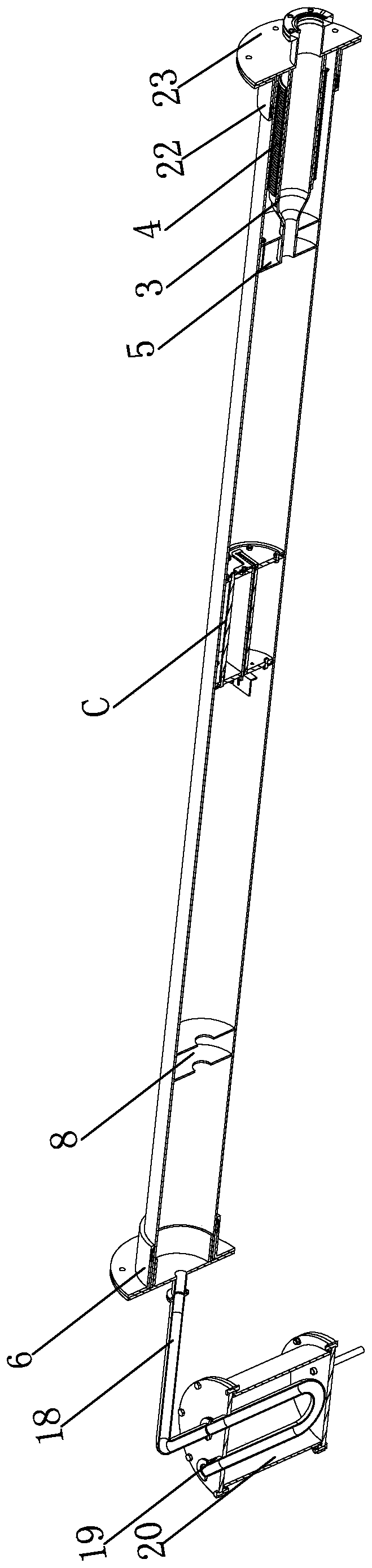

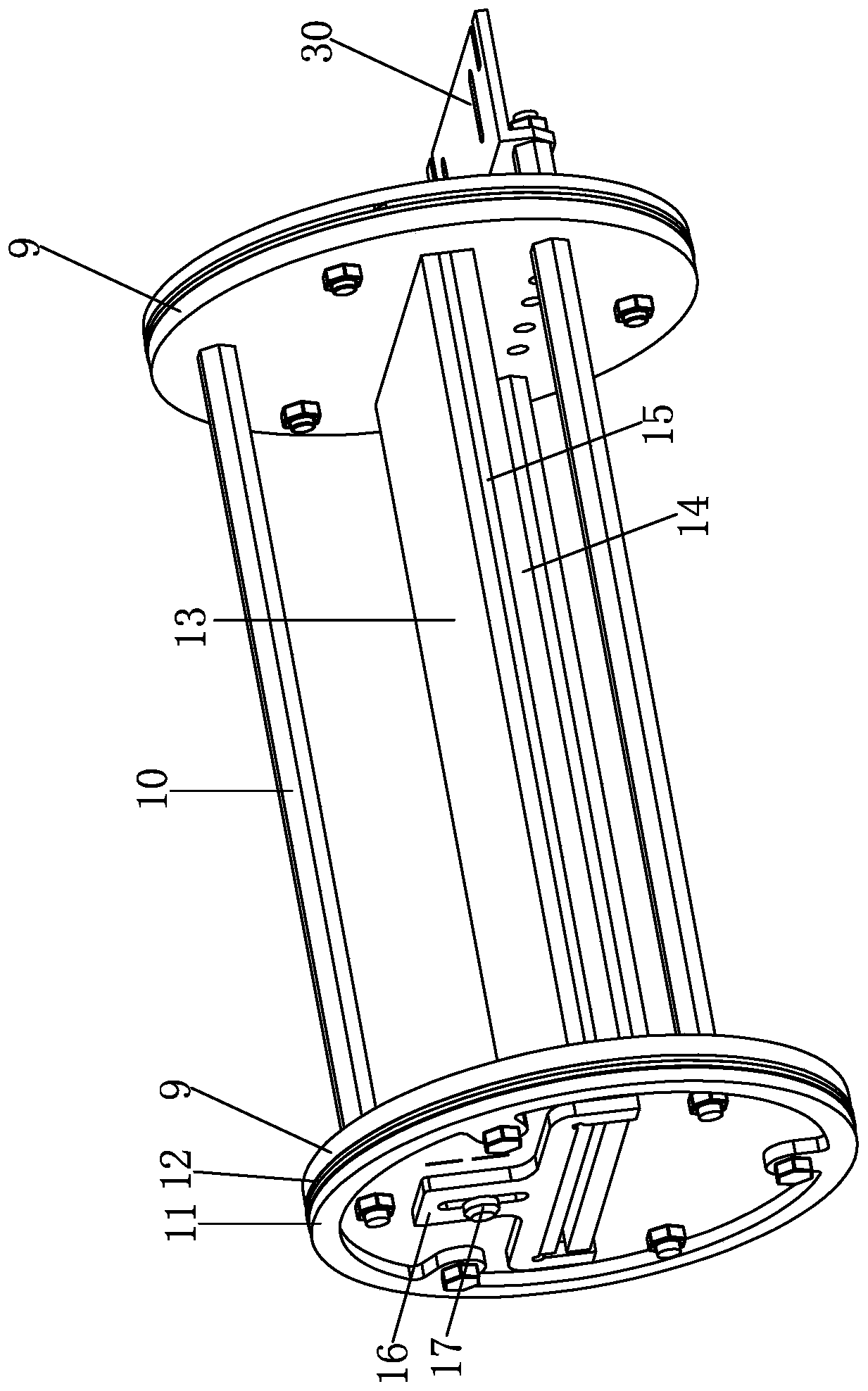

[0025] Step a: Design a thin film preparation equipment, such as figure 1 - As shown in 3, the thin film preparation equipment mainly includes quartz tube 1, tube furnace 2, compression tube 3, internal cooling tube 4 and first heat resistance plate 5 and so on. Wherein, the pyrolysis part of the quartz tube 1 is located in the furnace cavity of the tube furnace 2, which is an outsourced part for heating the quartz tube. In this case, a light-loading hole 2a is opened on the furnace cover of the tube furnace 2, and the light-loading hole 2a runs through the top and bottom surfaces of the furnace cover, and the light-loading hole 2a allows short-wavelength light to pass through.

[0026]The inlet end of the quartz tube 1 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com