UHPC pipe-concrete prefabricated assembled combined pier with socket joint type connector and construction method of pier

A prefabricated assembly and construction method technology, applied in the direction of erecting/assembling bridges, bridges, bridge materials, etc., can solve the problems of long construction period of bridge piers, inconvenient factory manufacturing, etc., to ensure structural quality, improve construction speed, and good bending resistance performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This embodiment discloses a construction method for a UHPC pipe-concrete prefabricated assembled bridge pier with a socket joint, including the following steps:

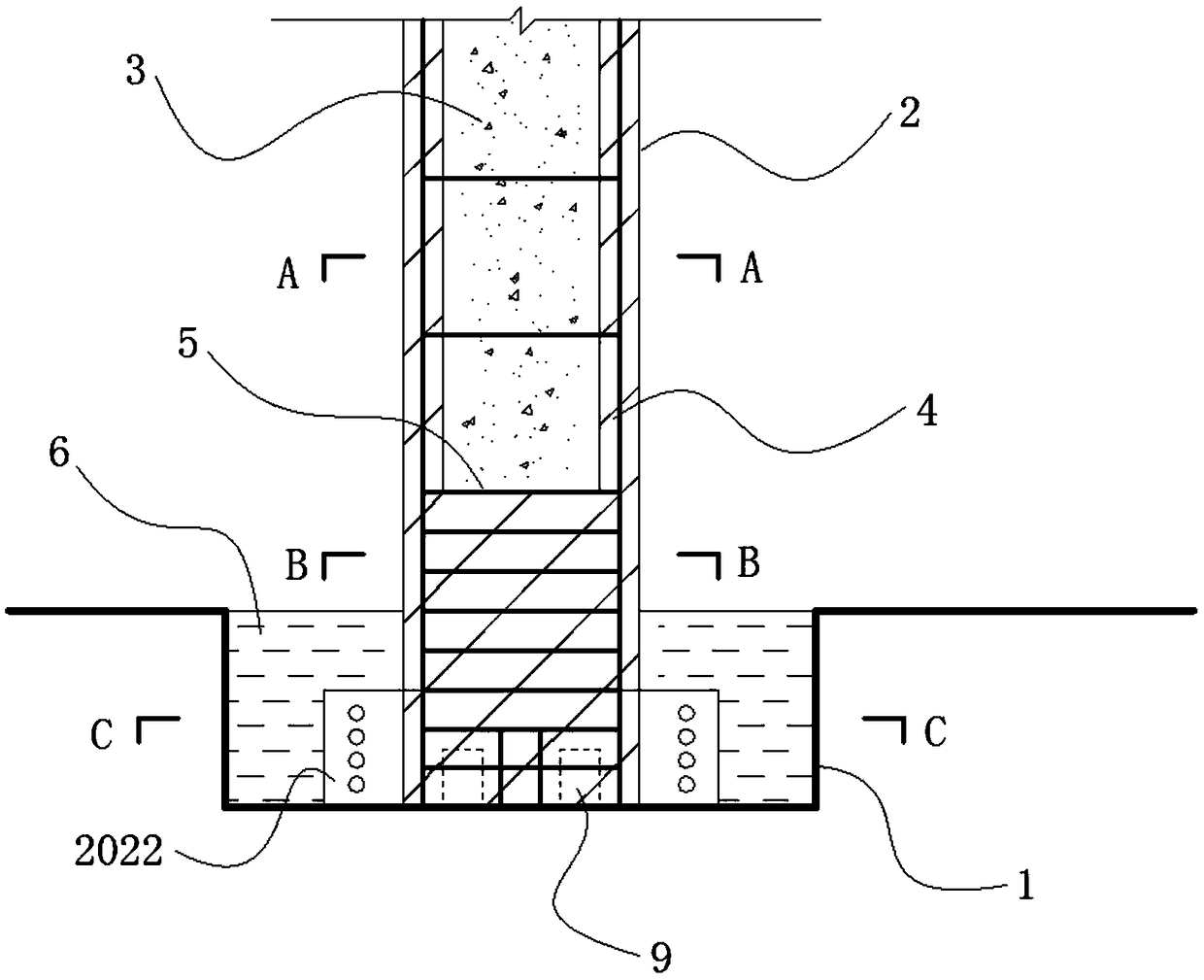

[0039] 1) According to the geological conditions, the foundation part of the construction site should be improved. A base hole 1 is arranged on the upper surface of the foundation. Wherein, two bolts 9 are embedded in the bottom of the base hole 1 .

[0040] 2) Prefabricated pier body. Wherein, the pier column body includes a UHPC part hollow column 2 and an ordinary concrete column 3 . The UHPC partially hollow column 2 includes a hollow UHPC tube 201 and a solid UHPC column 202 . The solid UHPC column 202 is disposed at the bottom of the hollow UHPC tube 201 . The hollow UHPC tube 201 and the solid UHPC column 202 are integrated. Ordinary concrete is poured into the cavity of the hollow UHPC pipe 201 to form an ordinary concrete column 3 . The hollow column 2 of the UHPC part has longitudinal stress ba...

Embodiment 2

[0052] see figure 1 , this embodiment discloses a UHPC pipe-concrete prefabricated assembled composite bridge pier with socket joints prepared by the method described in Embodiment 1, including a pier column body implanted into the base 6 .

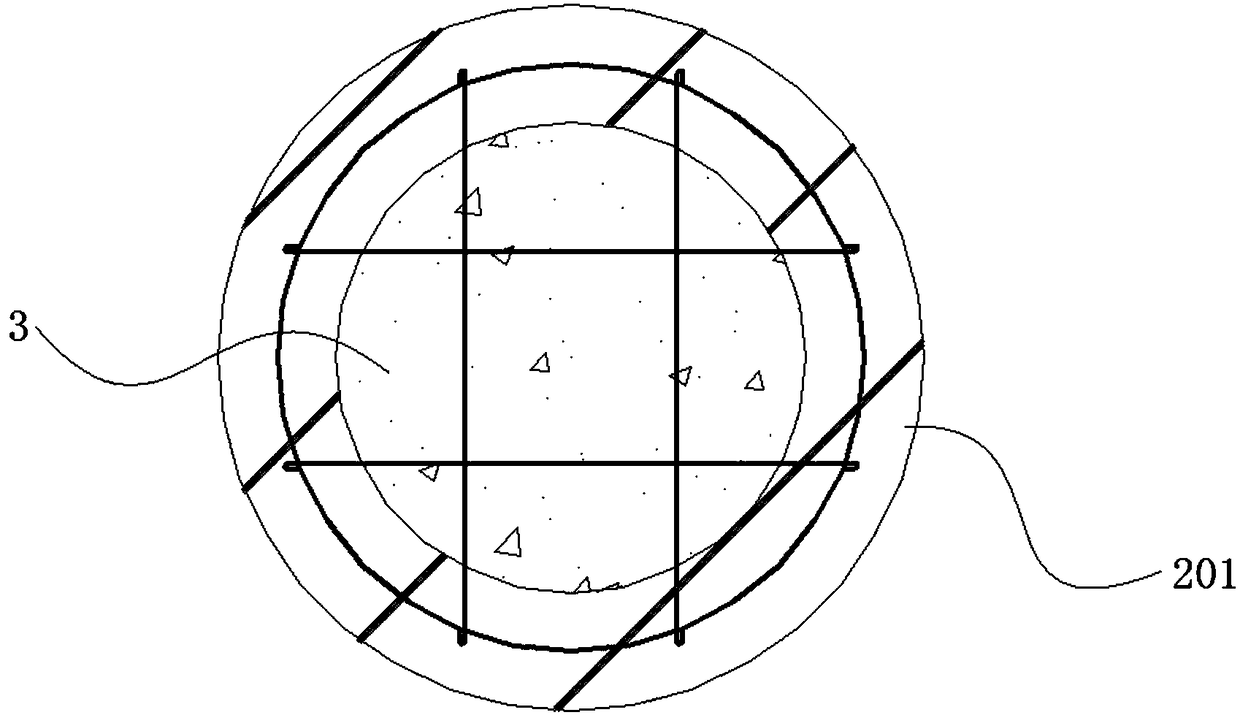

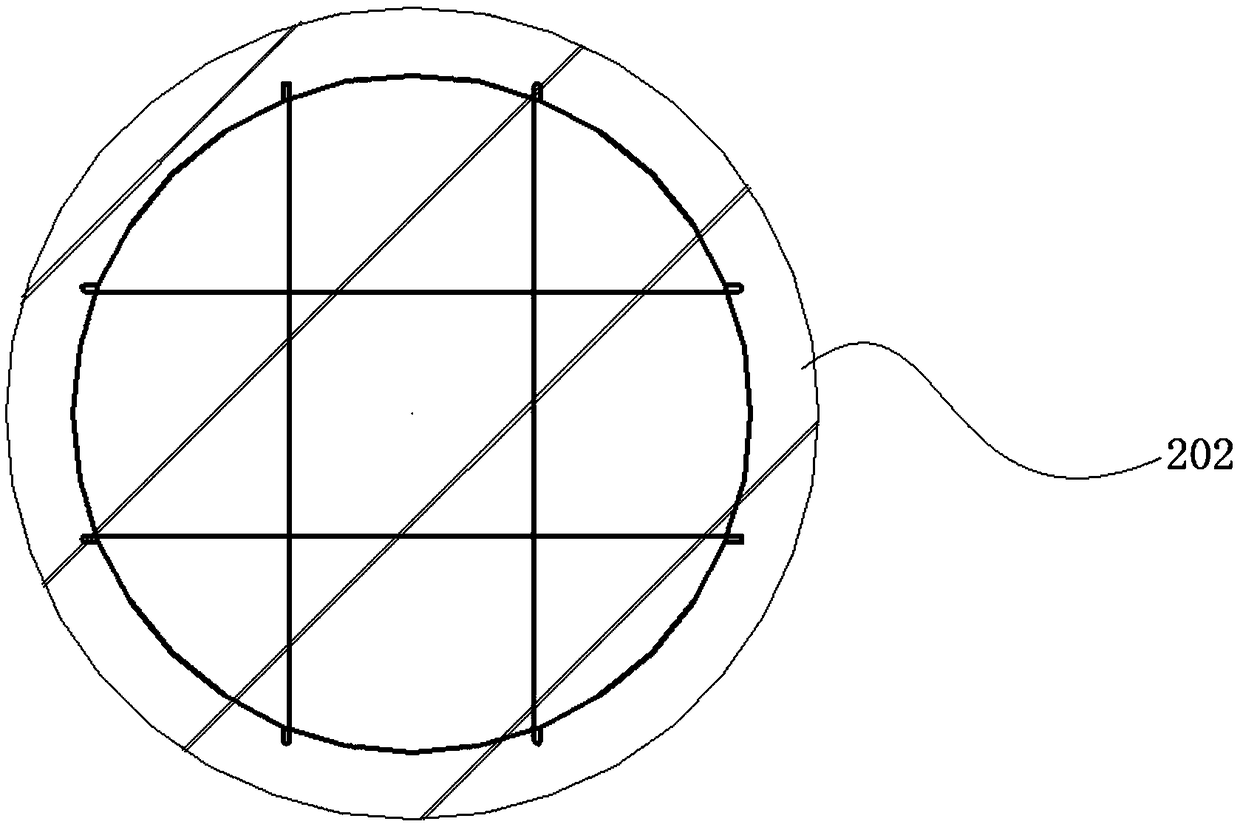

[0053] see figure 2 , 3and 4, the pier column body includes a UHPC part hollow column 2 and an ordinary concrete column 3 . The UHPC partially hollow column 2 includes a hollow UHPC tube 201 and a solid UHPC column 202 . The hollow UHPC tube 201 is a hollow circular tube. The solid UHPC column 202 is a solid cylinder. The solid UHPC column 202 is disposed at the bottom of the hollow UHPC tube 201 . The hollow UHPC tube 201 and the solid UHPC column 202 are integrated. Ordinary concrete is poured into the cavity of the hollow UHPC pipe 201 to form an ordinary concrete column 3 . The hollow column 2 of the UHPC part has longitudinal stress bars 4 and stirrups 5 inside. The longitudinal stress bars 4 and stirrups 5 together form a r...

Embodiment 3

[0056] see Figure 5 , this embodiment discloses a UHPC pipe-concrete prefabricated assembled composite bridge pier with socket joints prepared by the method described in Embodiment 1, including a pier column body implanted into the base 6 .

[0057] see Figure 6 , 7 and 8, the pier column body includes a UHPC part hollow column 2 and an ordinary concrete column 3 . The UHPC partially hollow column 2 includes a hollow UHPC tube 201 and a solid UHPC column 202 . The hollow UHPC tube 201 is a hollow square tube. The solid UHPC column 202 is a solid square column. The solid UHPC column 202 is disposed at the bottom of the hollow UHPC tube 201 . The hollow UHPC tube 201 and the solid UHPC column 202 are integrated. Ordinary concrete is poured into the cavity of the hollow UHPC pipe 201 to form an ordinary concrete column 3 . The hollow column 2 of the UHPC part has longitudinal stress bars 4 and stirrups 5 inside. The longitudinal stress bars 4 and stirrups 5 together for...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap