Composite drilling tool

A technology of compound drilling and drilling tools, which is applied in the direction of drill bits, drilling equipment, earthwork drilling and production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

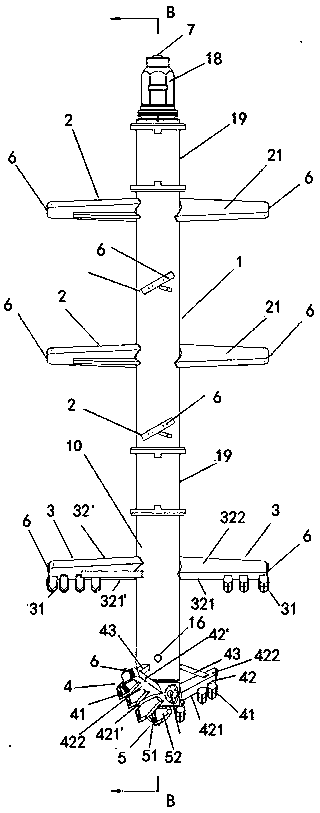

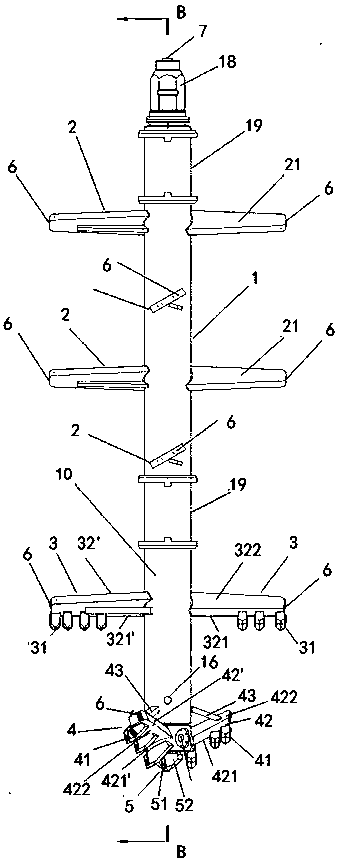

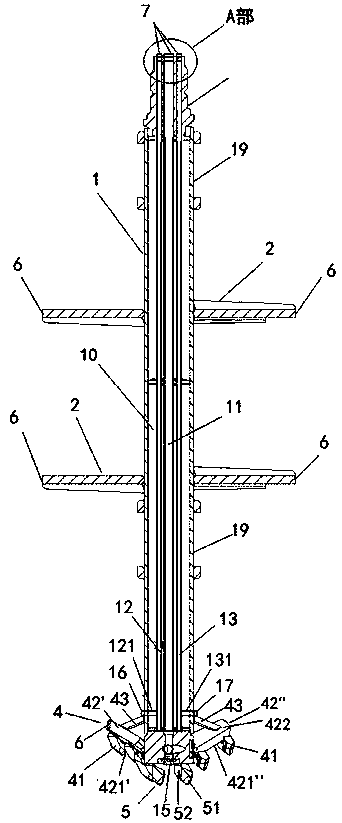

[0031] The composite drilling tool of the present invention will be further described below in conjunction with the accompanying drawings.

[0032] A composite drilling tool, the drilling tool 1 includes: a hollow pipe body 10, a grouting pipe 11, a gas pipe 12 and a solidification liquid pipe 13 arranged in the inner cavity of the hollow pipe body, and a first Valve 15, the second valve 16 and the third valve 17 located below the outer wall of the hollow tube, the outer hexagonal joint 18 located at the upper end of the hollow tube, the outer wall of the hollow tube has a supporting groove 19; the first cutting wing 3 includes the second A cutting body 31 and the first wing; the second cutting wing 4, including the second cutting body 41 and the second wing; the front end cutting body 5, including the third cutting body 51 and the third handle; multiple groups of stirring Leaf 2, wear plate 6 and sealing sleeve 7; wherein:

[0033] The grouting pipe 11, air pipe 12 and solid...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap