System and method for controlling radon seepage in blasting uranium ore heap of underground uranium mine stope

An underground uranium and radon seepage technology, applied in underground mining, pump control, surface mining, etc., can solve the problems of increasing the ventilation air volume, increasing the radon discharge volume, increasing the ventilation air volume, etc., and improving the stability and reliability. , Wide range of application, the effect of reducing radon concentration value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

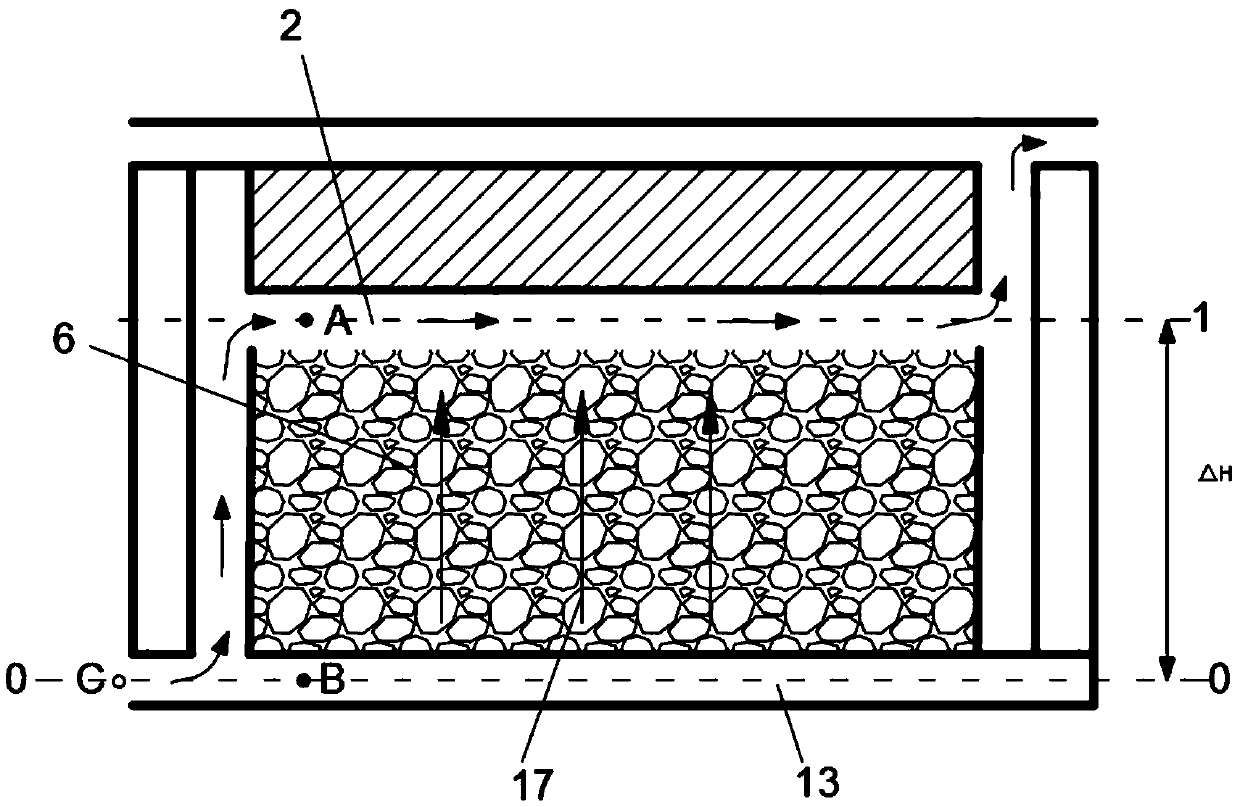

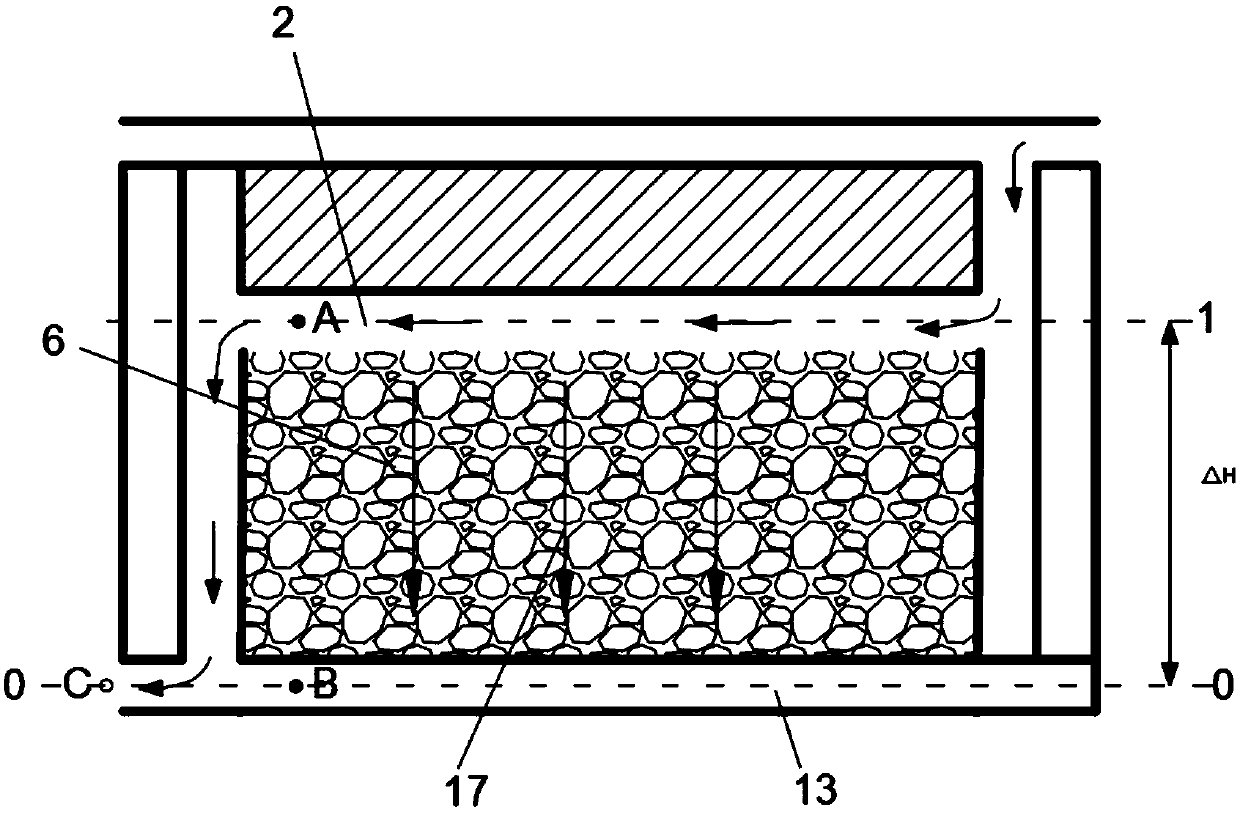

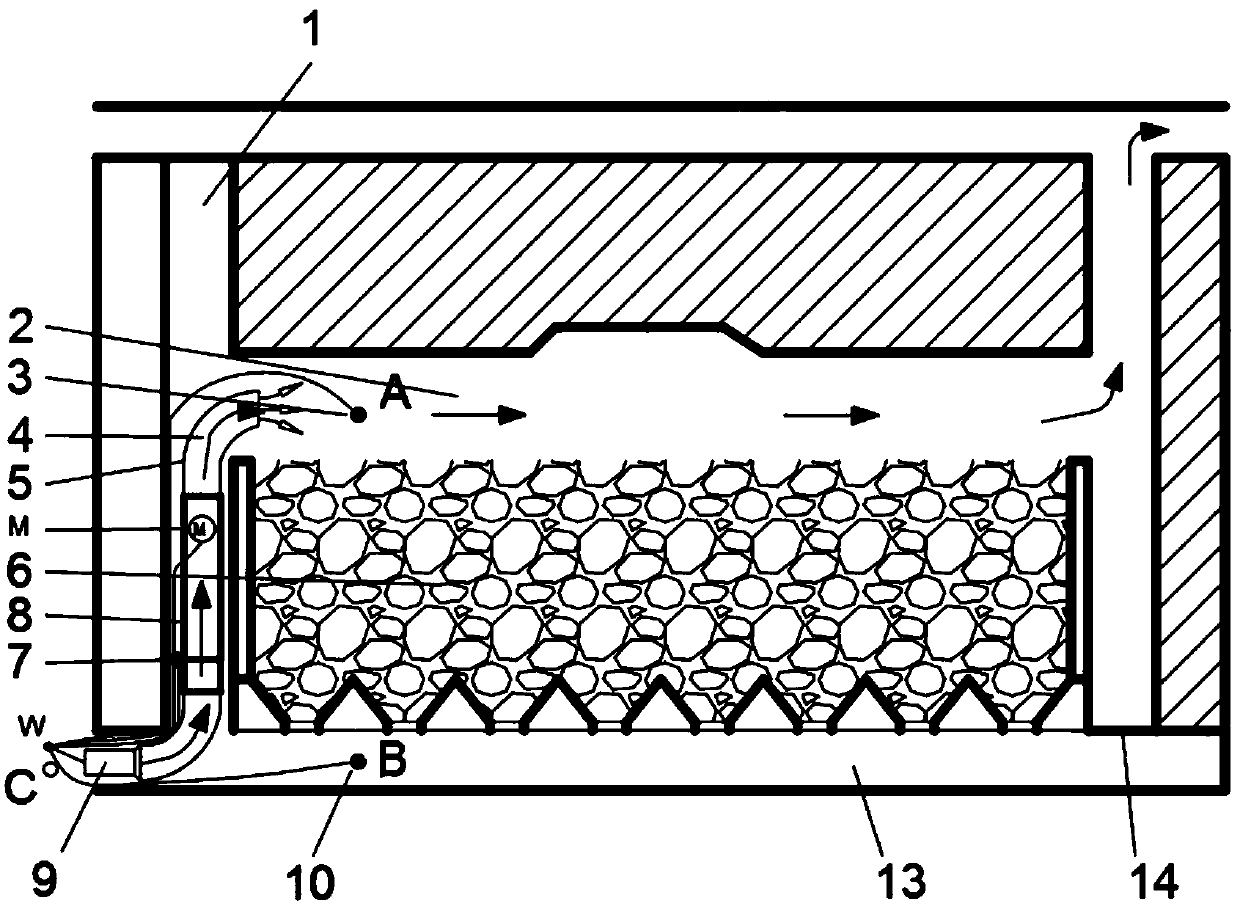

[0048] The purpose of the present invention is to solve such as attached figure 1 , attached figure 2 The problem of the stope ventilation method of the underground uranium mine retention method shown in the control of radon seepage in the stope blasting uranium ore pile. Due to the pressure loss in the air supply process of the Shunlu shaft, there is a large pressure difference between the upper and lower surfaces of the blasted uranium ore pile 6, and there is an airflow passing through the inside of the ore pile (the seepage direction 17 is shown in the figure), which increases the radon in the ore pile. of precipitation. The present invention adjusts and controls the air pressure difference between the upper and lower surfaces of the blasted uranium ore pile 6 through a local mechanical ventilation method, so that the gas seepage velocity in the ore pile is close to zero, minimizes the precipitation of radon generated by the ore pile into the working space of the stope, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com