High-pressure fuel pump for a fuel injection system

A fuel injection system and high-pressure fuel pump technology, applied in fuel injection pumps, fuel injection devices, charging systems, etc., can solve problems such as piston sticking, achieve increased service life, internal friction optimization, and large rotational movement components Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

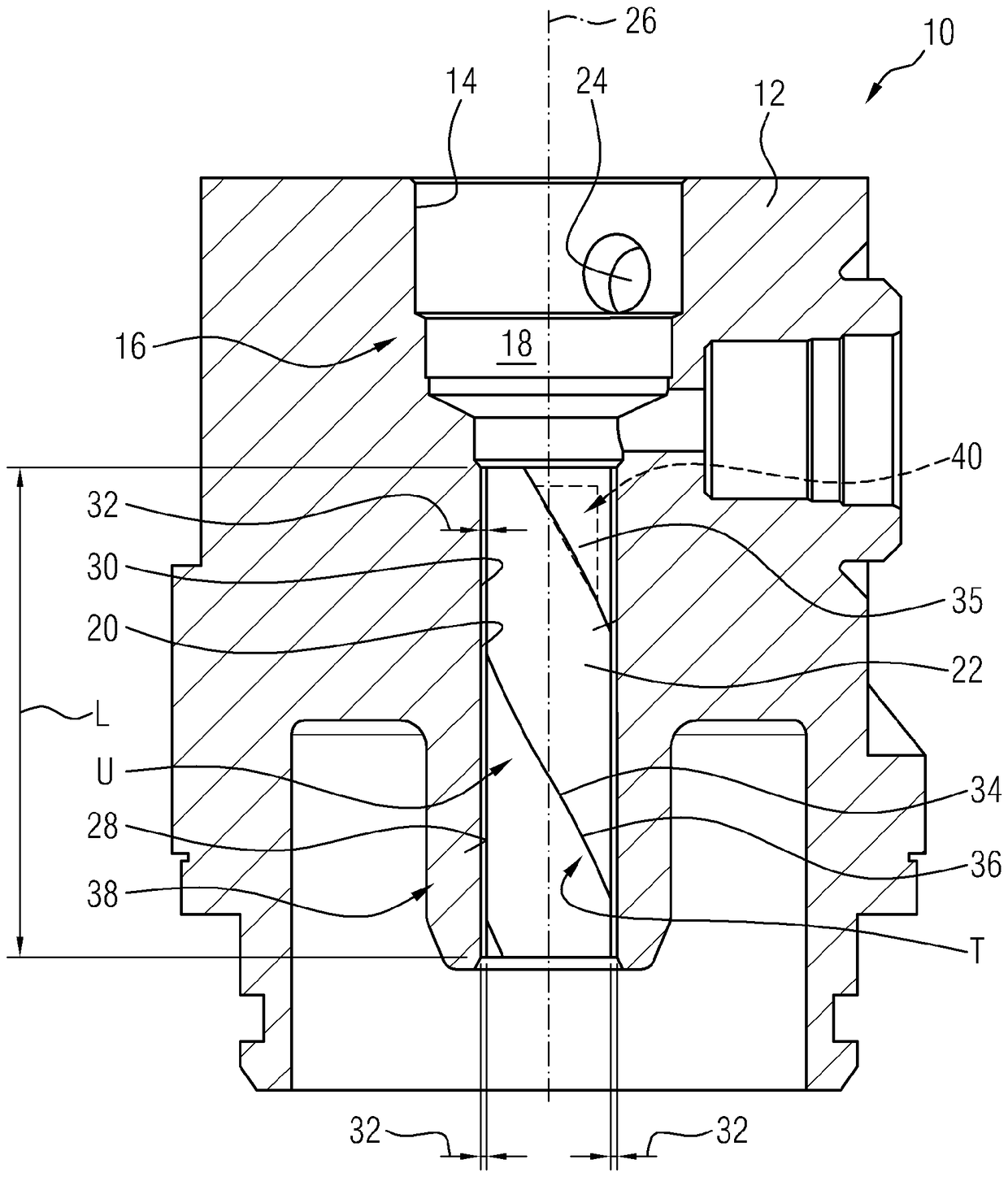

[0032] figure 1 A schematic sectional view of a high-pressure fuel pump 10 is shown, with which high pressure is applied to fuel, in particular gasoline. The high-pressure fuel pump 10 has a housing 12 in which a housing bore 14 is formed, which forms a pressure chamber 18 at an end region 16 . Adjacent to the end region 16 , the housing bore 14 forms a guide bore 20 in which a pump piston 22 is arranged. During operation, fuel is supplied to the pressure chamber 18 via the feed hole 24 . The pump piston 22 moves upwards and downwards along the displacement axis 26 in the guide bore 20 and thus reduces the volume of the pressure chamber 18 . In this way, the fuel located in the pressure chamber 18 is compressed and thus has a high pressure applied thereto.

[0033] In the current embodiment, the guide hole 20 is directly formed in the housing 12 . However, it is also conceivable that an additional sleeve is inserted into the housing bore 14 , in which sleeve the guide bore...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com