Self-reset single-side bolt fastener system

A unilateral bolt and fastener technology, applied in the direction of threaded fasteners, screws, connecting components, etc., to achieve the effects of uniform bearing, good compressive and shear mechanical properties, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

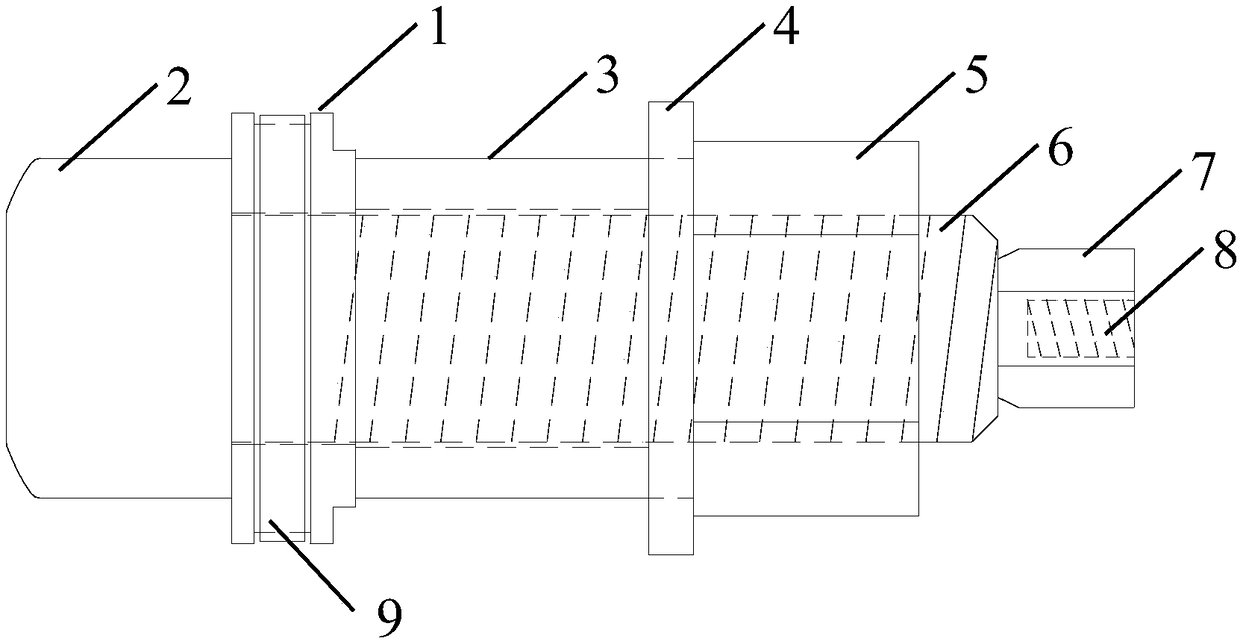

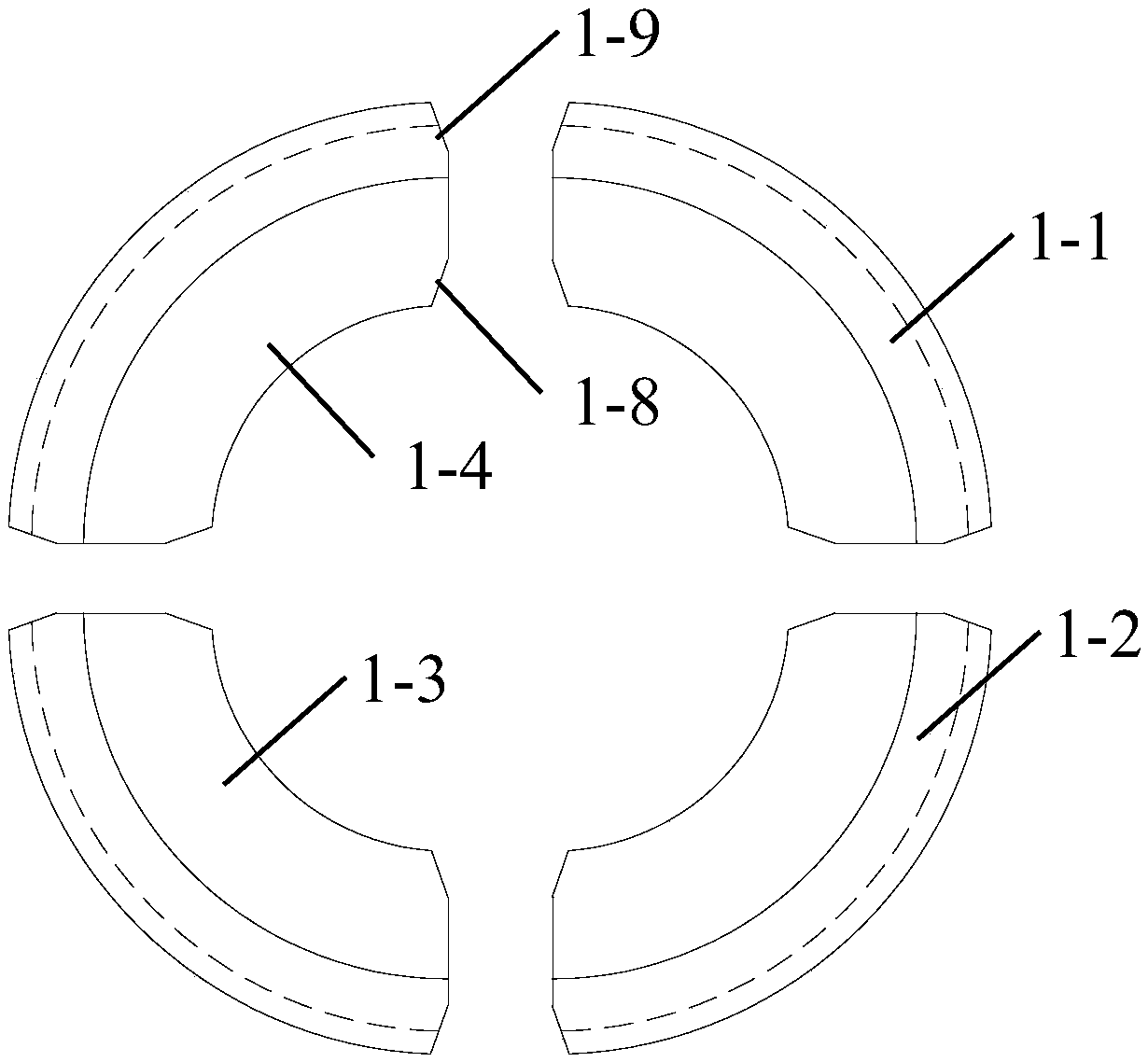

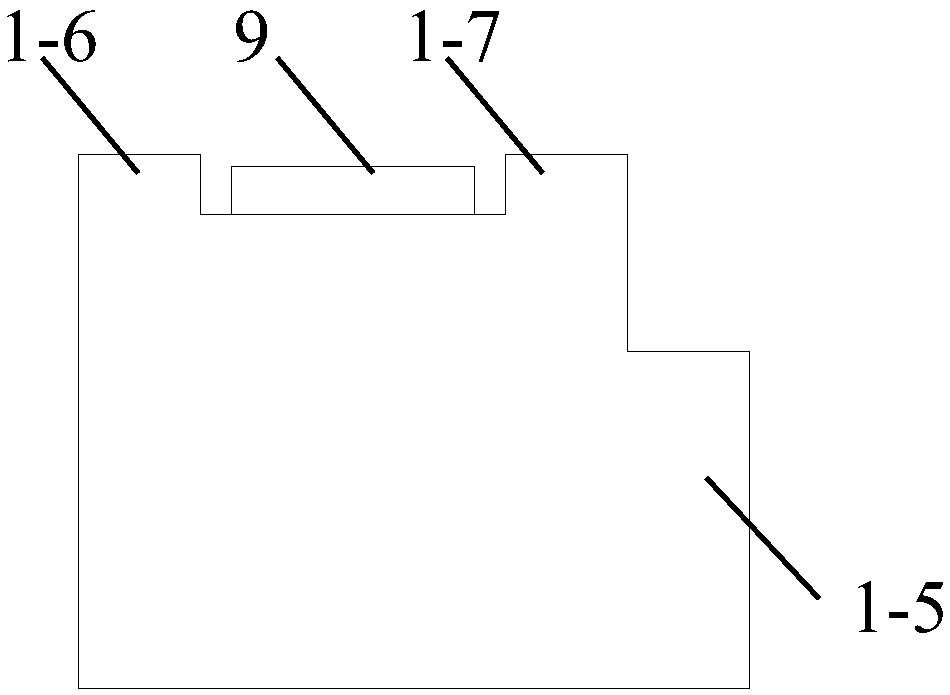

[0026] Embodiment 1: The present invention includes split machining gasket 1-1, split machining gasket 1-2, split machining gasket 1-3, split machining gasket 1-4, round head bolts 2. Sleeve 3, washer 4, nut 5, plum blossom head 7, shape memory alloy flat ring 9, etc. The round head bolt 2 and the four split machining gaskets 1-1 to 1-4 are positioned and installed through the operating rod 8-2 and the operating top hook 8-4.

[0027] The shapes of the four split machining gaskets 1-1 to 1-4 are exactly the same, and the cut corners 1-8 and 1-9 are processed at the ends to facilitate the extrusion of the extrudable composite gasket. During the process, press against each other and keep stable.

[0028] Installation method:

[0029] 1. First assemble the four split machining gaskets 1-1~1-4 and the shape memory alloy flat ring 9 into an extrudable combined gasket 1 (such as Figure 5 shown), then insert the extrudable combined gasket 1, sleeve 3, washer 4, and nut 5 into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com