Movable and lockable equipment base

A locking and equipment technology, applied in the direction of mechanical equipment, mobile frame, engine frame, etc., can solve the problems of troublesome locking, unreliable locking, small contact area between the universal wheel and the ground, etc., and achieve beautiful appearance, Overcoming the effect of wheel leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

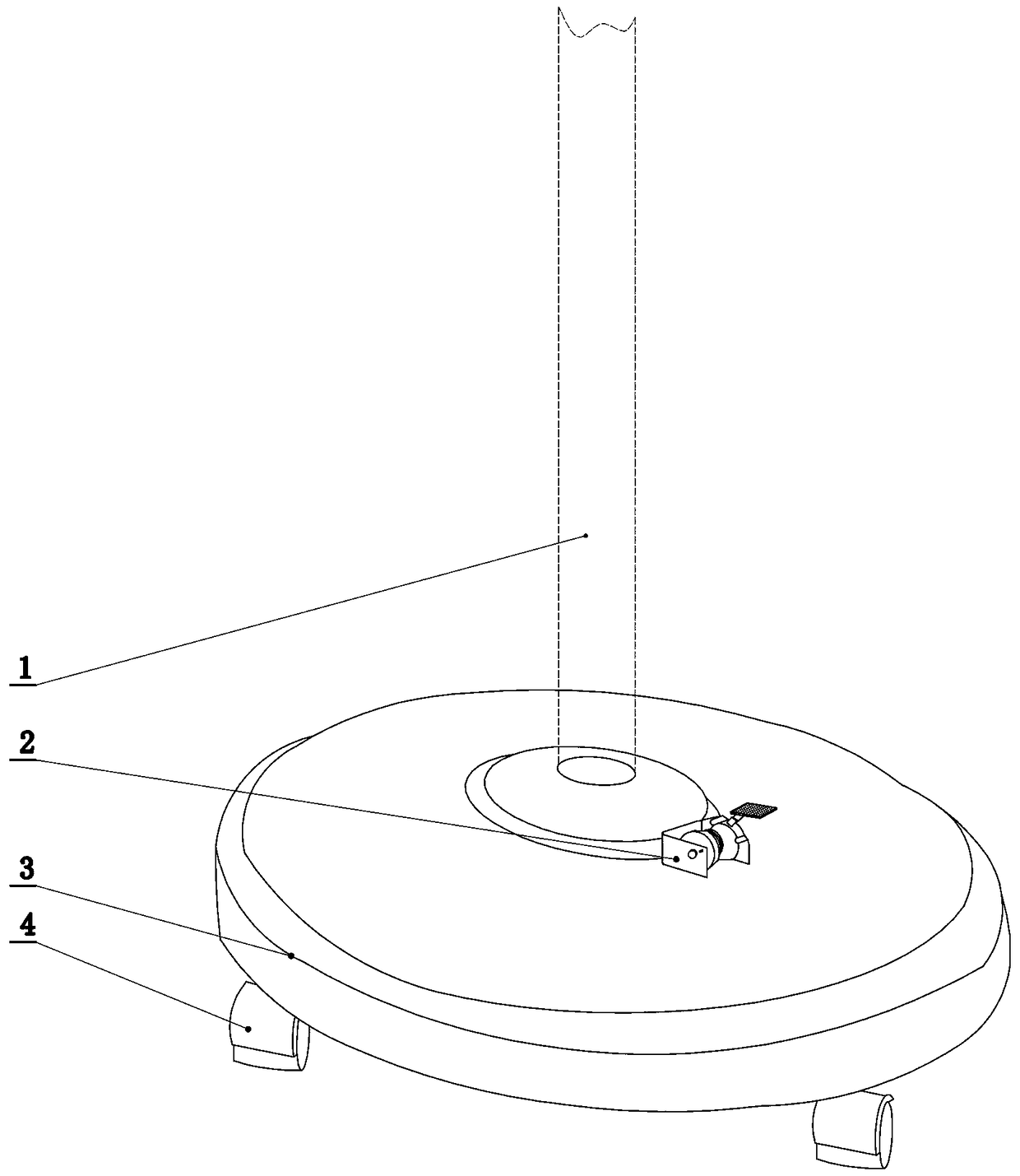

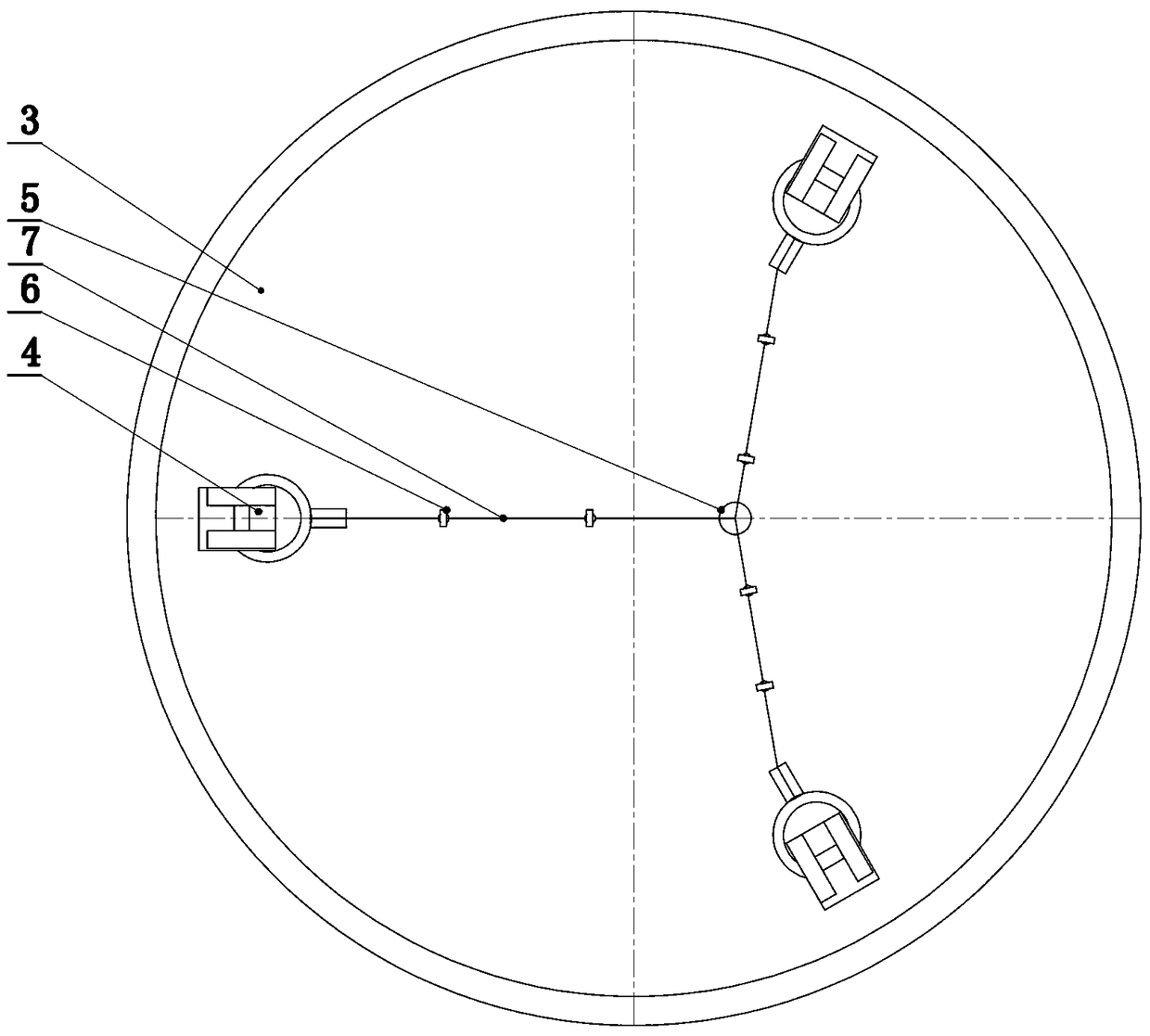

[0037] Below in conjunction with accompanying drawing, take floor fan base as example, the present invention will be further described. like Figure 1-2 As shown, a movable and locking equipment base includes: a base 3 with three base mounting holes 301 at the bottom, a universal wheel lifting assembly installed in the base mounting holes, and an inner sleeve for locking the universal wheel lifting assembly Tube locking assembly, locking winding wheels and swivel wheels for controlling base movement and locking status.

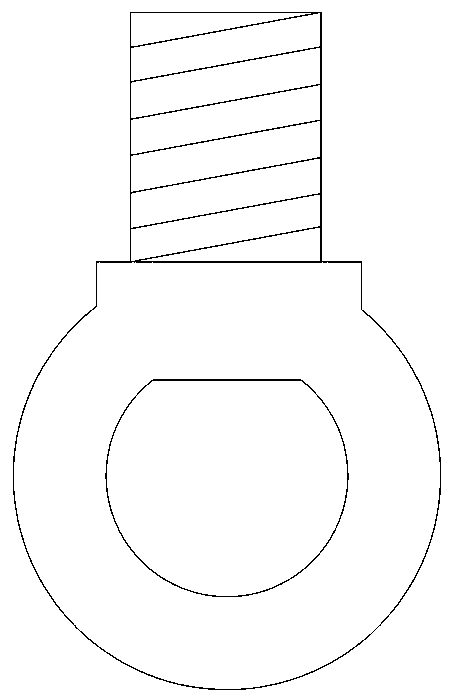

[0038] The universal wheel lifting assembly is formed by two inner and outer metal sleeves, and the outer sleeve 401 is installed on the bottom of the base through interference fit or through threads. The lifting sliding plate 406 on the upper end of the inner casing is located in the lifting chute 405 of the outer casing 401 , and the lifting compression spring 402 is installed on the inner casing 403 . The inner casing slides up and down along the lifting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com