Method and system for testing gap values of workpieces on basis of laser light

A gap and workpiece technology, applied in the field of measuring workpiece gap value based on laser, can solve the problems of low measurement accuracy and insufficient automatic judgment ability, and achieve the effect of high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

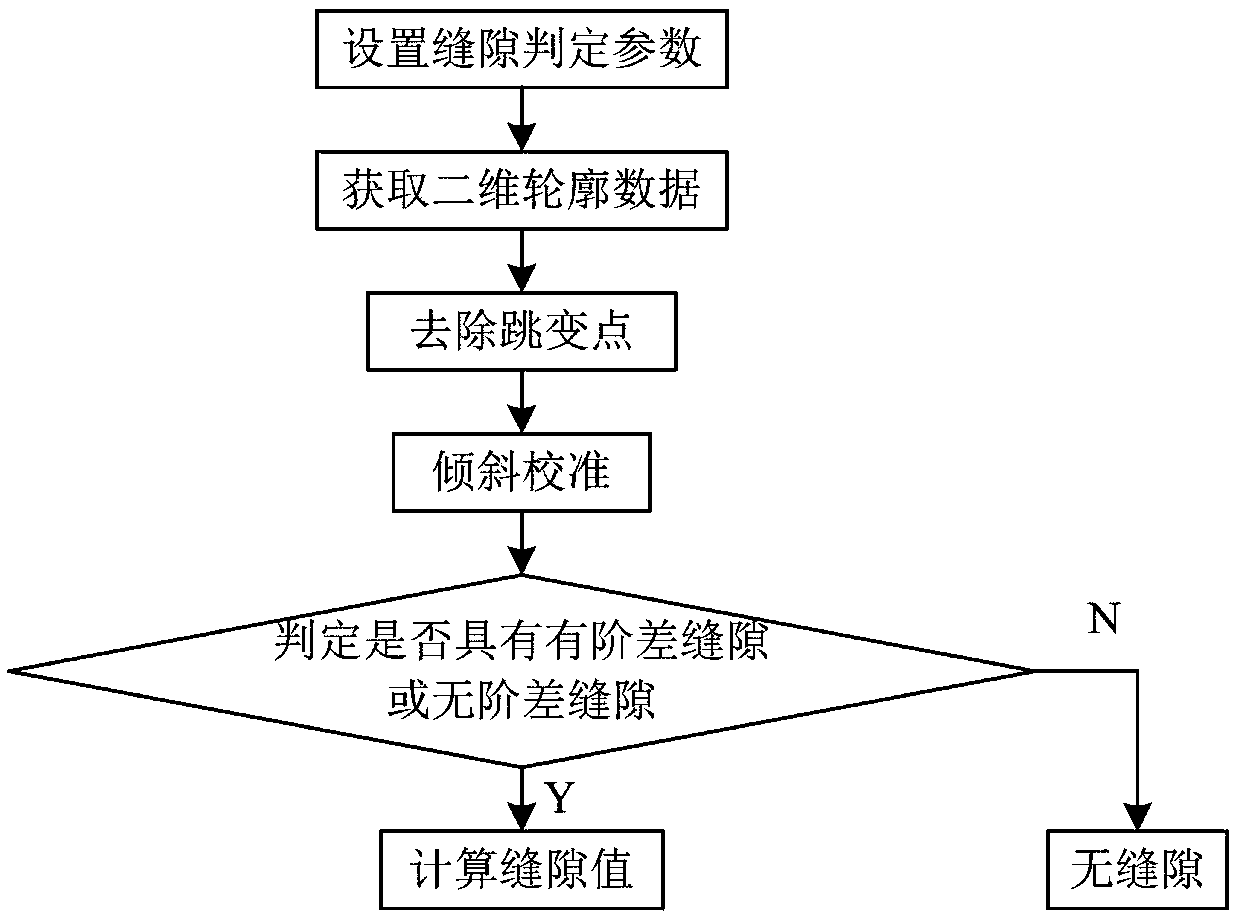

[0076] When two objects are close but not in direct contact, the distance between them is called the gap. The calculation of the gap also includes two parts, which are the judgment of the gap and the calculation of the size of the gap.

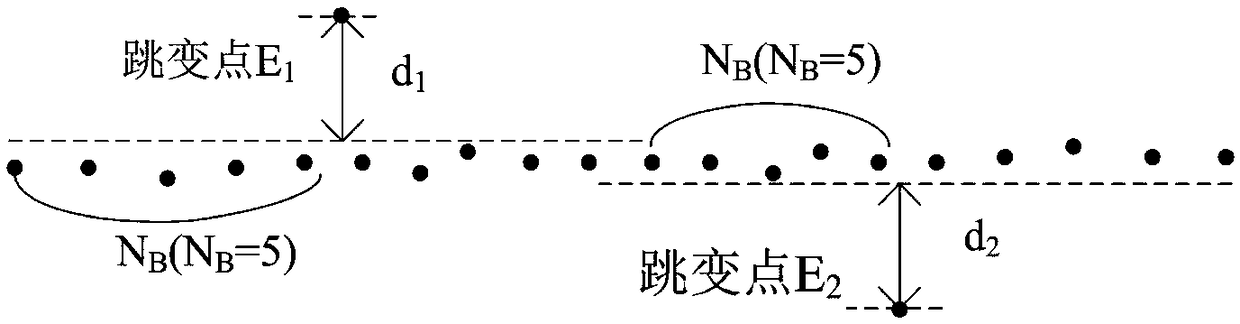

[0077] The idea of gap judgment and gap size calculation in the present invention is: the step difference gap judgment method is to use the gap judgment parameters to judge whether there are three consecutive planes in the two-dimensional contour data measured by the laser line scanning sensor, and the middle plane is located on the left and right planes Below , if it exists, the object has a gap with a step difference, and the size of the gap is equal to the length value of the middle plane in the contour data, that is, the intersection point B of the first plane and the second plane 1 and the intersection point C of the second plane and the third plane 1 The absolute value of the difference of the x-axis values. The non-step difference g...

Embodiment 2

[0134] Based on the above method, the present invention also provides a system for testing workpiece gap value based on laser, including:

[0135] The parameter setting module is used to set parameters, and the parameters include gap determination parameters, de-trip point parameters and tilt calibration parameters;

[0136] Workpiece contour acquisition module: used to scan the measured workpiece with a laser sensor, obtain the measured workpiece contour data, and analyze the measured workpiece contour data into two-dimensional contour data, the two-dimensional contour data is X containing N collection points Axis data and Z-axis data containing N collection points, where N is the total number of all collection points in the measured workpiece contour data;

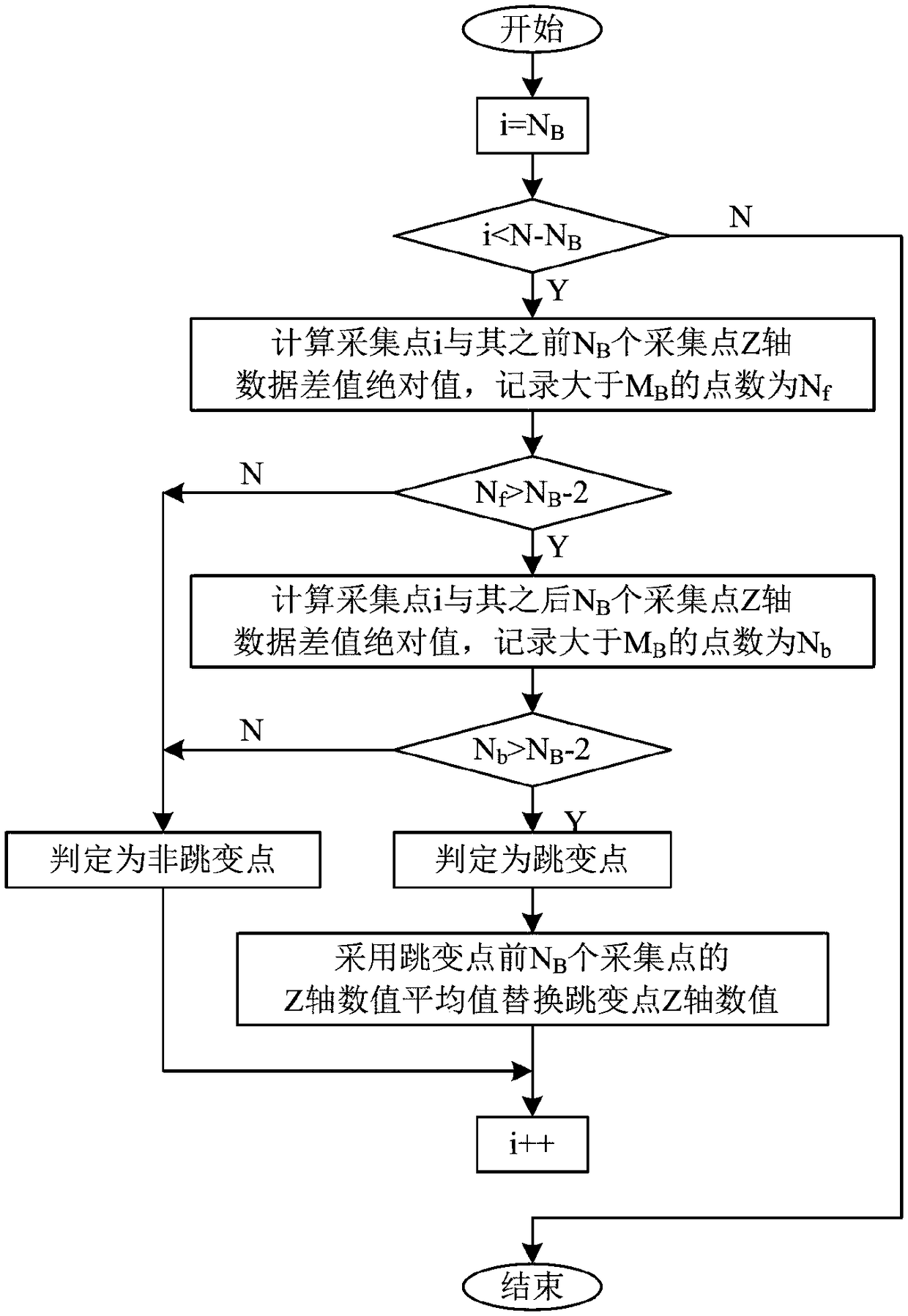

[0137] The trip point removal module is used to perform trip point removal processing on the two-dimensional contour data according to the trip point removal parameter;

[0138] An inclination calibration module, config...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com