Pressure measuring device and bicycle stepping sensor

A technology of a stepping sensor and a measuring device, applied in the field of sensors, can solve the problems such as the inability to arrange the life of the sensor and the limitation, and achieve the effects of simple structure, normal deformation, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

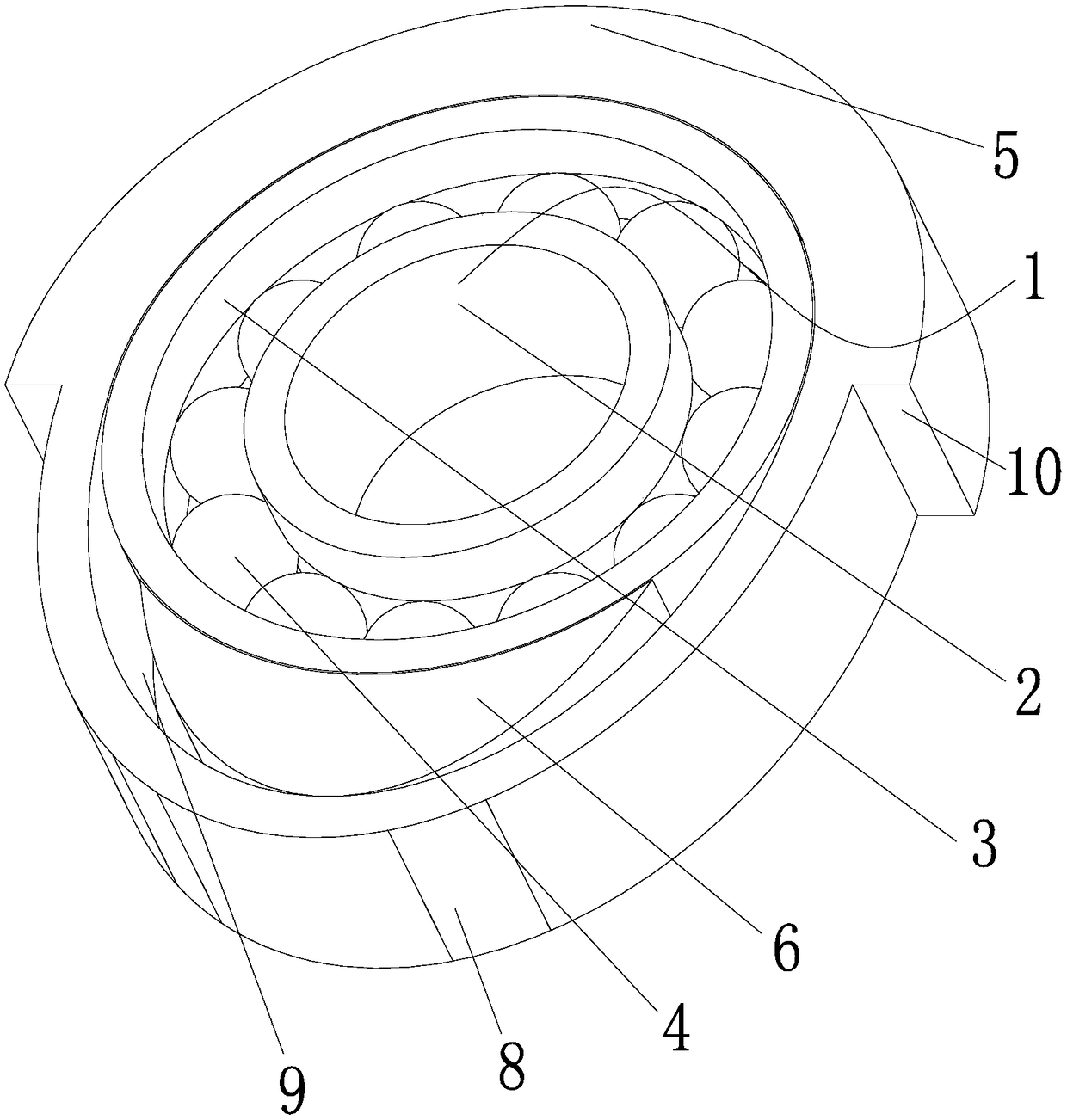

[0030] see figure 1 :

[0031] A pressure measurement device, comprising a bearing 1, an elastic member 5, a cushion block 6 and a force sensor 8, a cushion block 6 is arranged inside the elastic member 5, the elastic member 5 and the cushion block 6 constitute the installation position of the bearing 1, and the bearing 1 is arranged on an elastic In the part 5, the force sensor 8 is arranged on the outside of the elastic part 5, specifically:

[0032] An elastic member 5 is sleeved on the outer side of the bearing 1, and the elastic member 5 is made of spring steel or other elastic materials to ensure the measurement life. The elastic member 5 is a cylinder, and the inner side of the elastic member 5 is provided with an oval hole, and the outer periphery of the elastic member 5 can be circular or also oval. The oval hole includes a semicircular part and an elliptical part or a parabolic part, the semicircular part and the elliptical part or parabolic part form a whole, the ...

no. 2 example

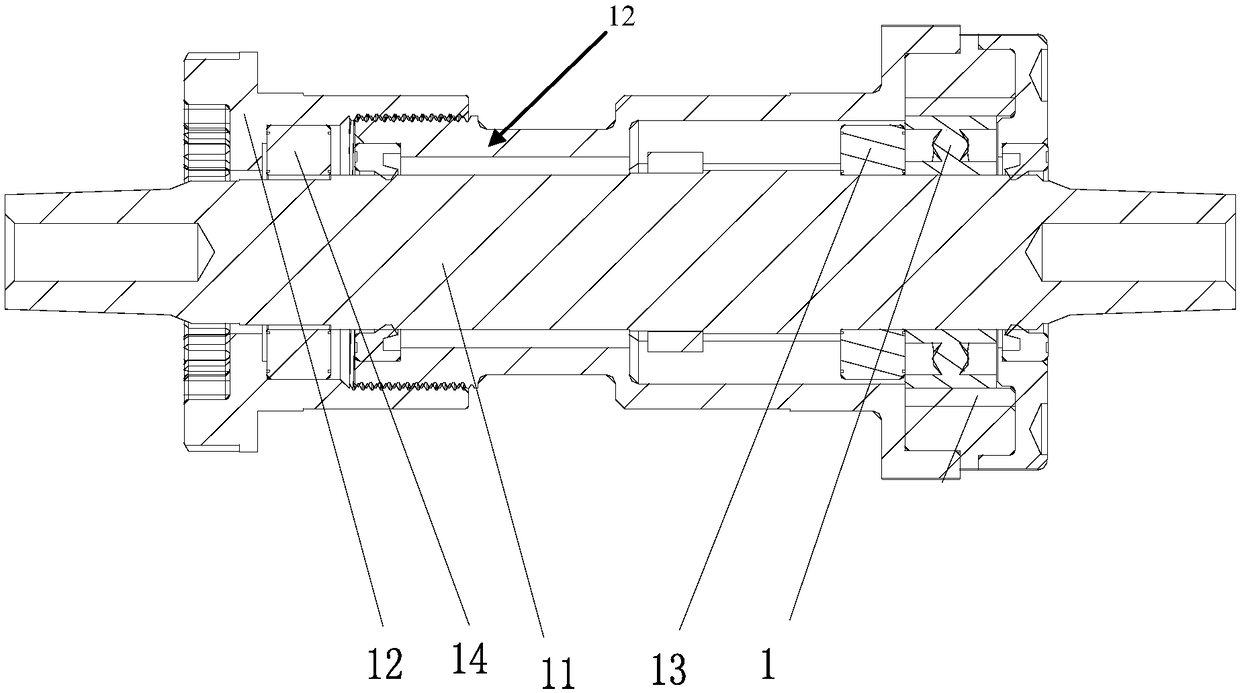

[0049] see Figure 1-3 :

[0050] This embodiment is the application of the pressure measuring device on the bicycle axis torque sensor 8, specifically:

[0051] The outer side of the bearing 1 is sleeved with an elastic piece 5, the elastic piece 5 and the arc part of the pad 6 constitute the installation position of the bearing 1, the elastic piece 5 is columnar, and the columnar elastic piece 5 includes an oval hole, which includes A semicircular part and an elliptical part, the semicircular part and the elliptical part form a whole, the outer side of the semicircular part bearing 1 is closely attached, the elastic part 5 is arranged in the end cover of the moment axis, and the elastic part 5 The curvature of the periphery at the top position of the oval hole is greater than the curvature at other positions, so that the periphery of the elastic member 5 is not in contact with the central axis at the top position of the oval hole, and the periphery of the elastic member 5 i...

no. 3 example

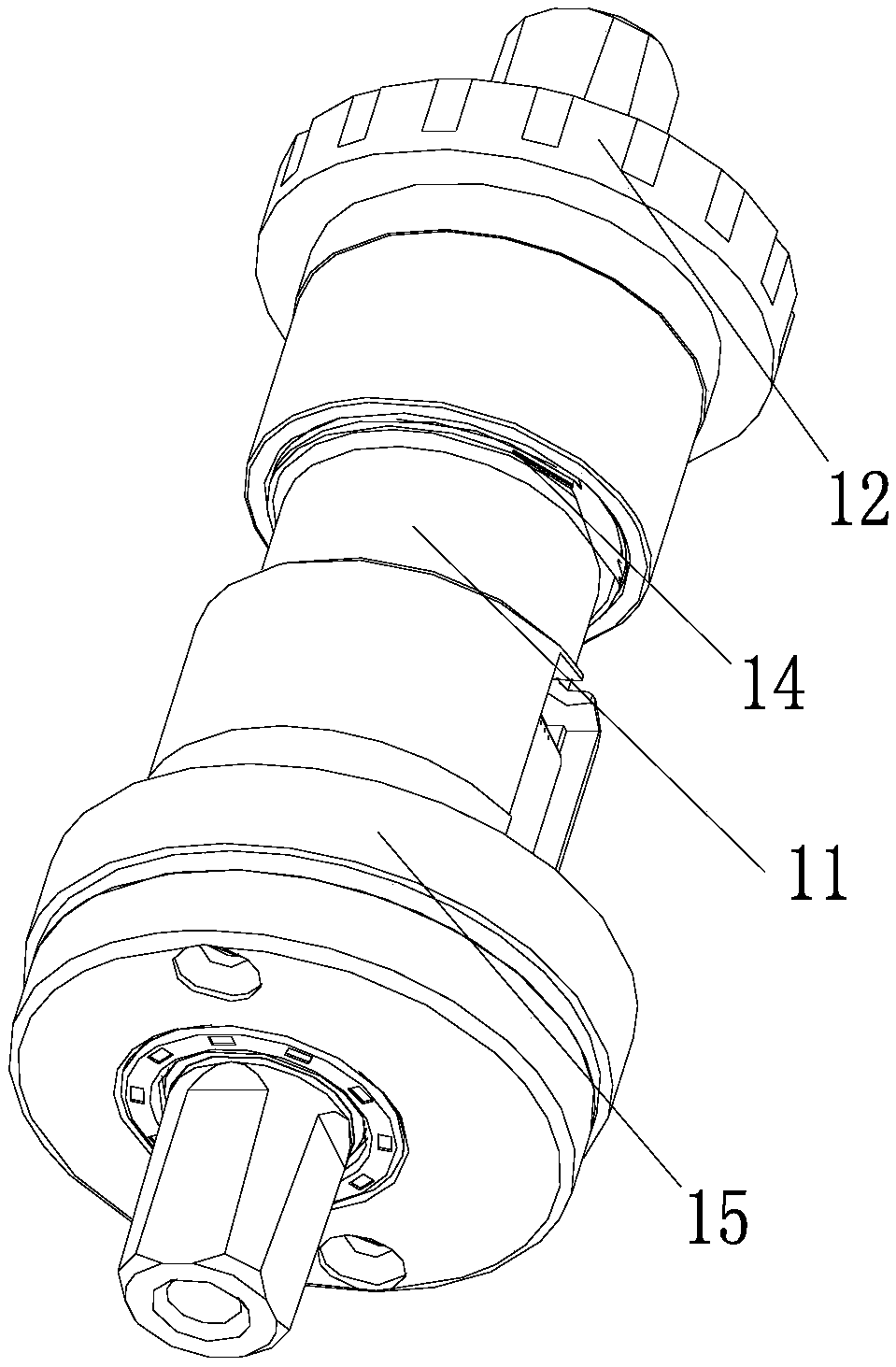

[0064] see figure 1 , Figure 4 with Figure 5 :

[0065] Compared with Embodiment 1 and Embodiment 2, this solution does not set a mounting protrusion and directly uses elastic parts to mount it. Compared with Embodiment 2, this solution cancels the protection of the bearing and uses the mounting position of the end cover to achieve protection. Specifically:

[0066] A pressure measurement device, comprising a bearing 1, an elastic member 5, a cushion block 6 and a force sensor 8, a cushion block 6 is arranged inside the elastic member 5, the elastic member 5 and the cushion block 6 constitute the installation position of the bearing 1, and the bearing 1 is arranged on an elastic Inside the member 5, the force sensor 8 is arranged outside the elastic member 5.

[0067] An elastic member 5 is sleeved on the outer side of the bearing 1, and the elastic member 5 is made of spring steel or other elastic materials to ensure the measurement life. The elastic member 5 is a cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com