Paint foaming test method

A test method and paint technology, applied in the field of automobile manufacturing, can solve problems such as undiscovered treatment methods, increased production costs, and troubles in vehicle manufacturing, and achieve the effect of avoiding large-area paint foaming and reducing the probability of paint foaming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

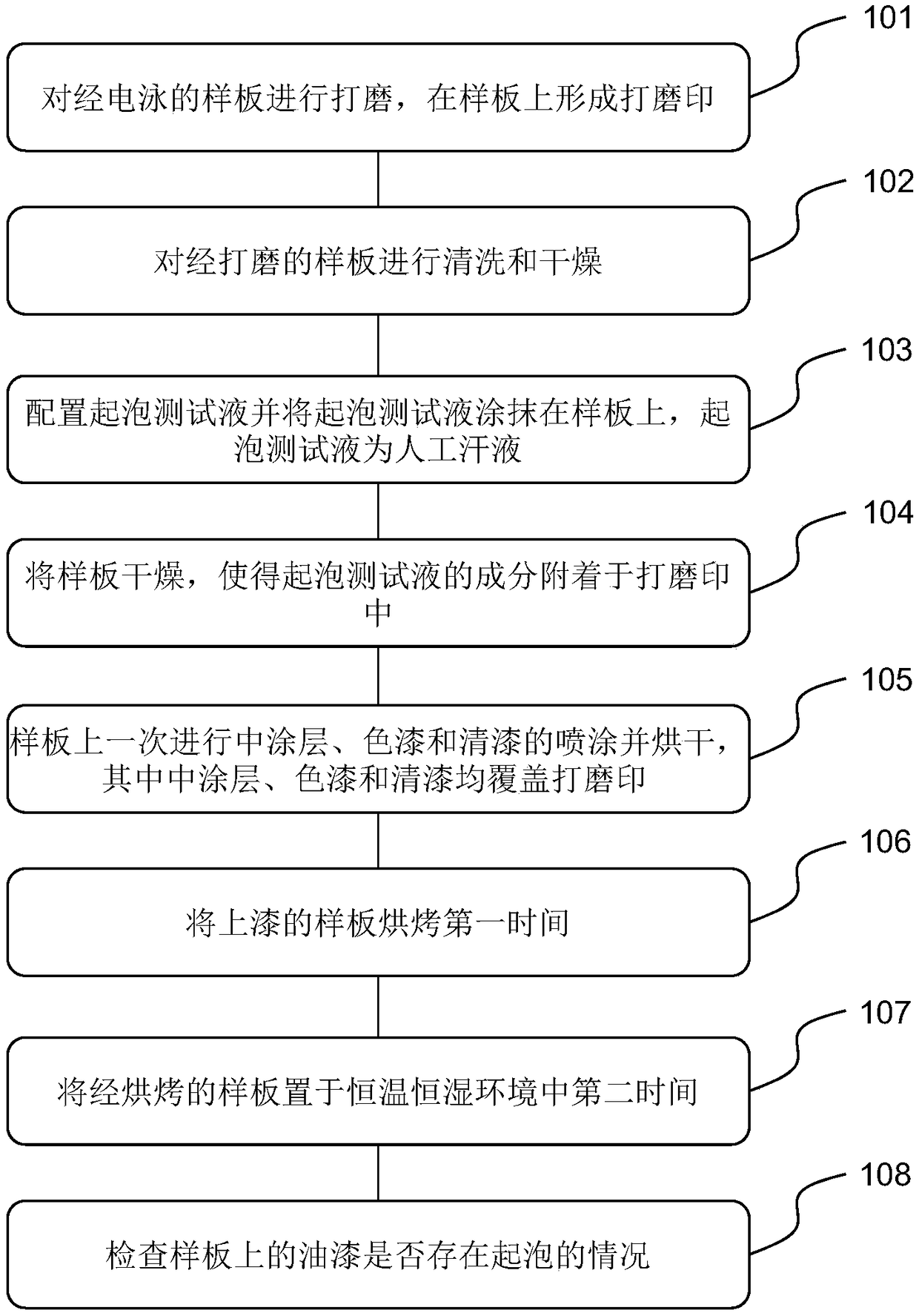

[0025] Before introducing the paint bubbling test method of the present invention, the process of finding the cause of the paint surface bubbling defect is firstly introduced. Finding the cause of blistering defects on the paint surface is as important as proposing a test method for paint blistering.

[0026] In order to find the cause of the blistering defect on the paint surface, a large amount of data on the blistering defect on the paint surface was first collected. Through the analysis of the big data, it was obtained that the blistering defect on the paint surface has the following characteristics:

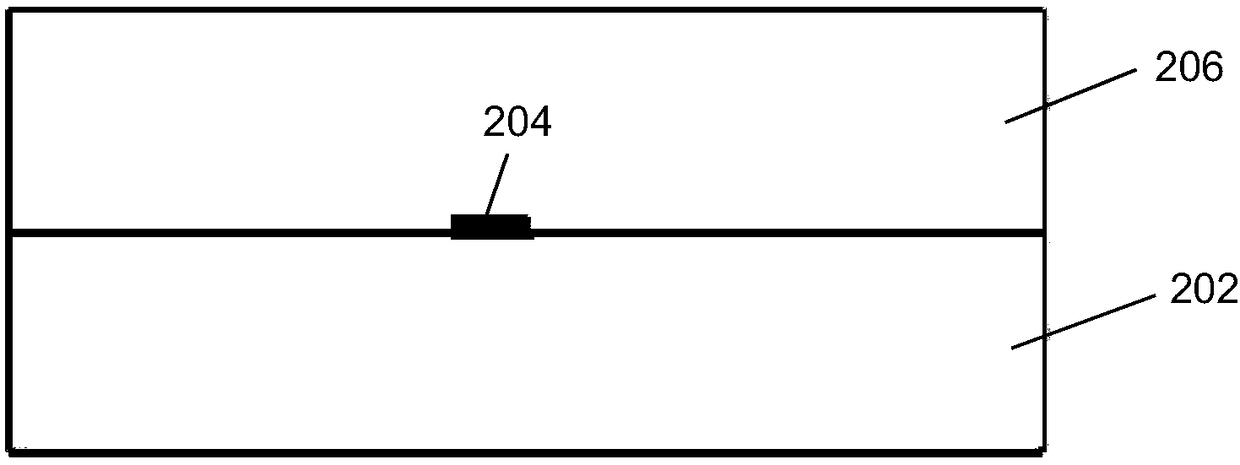

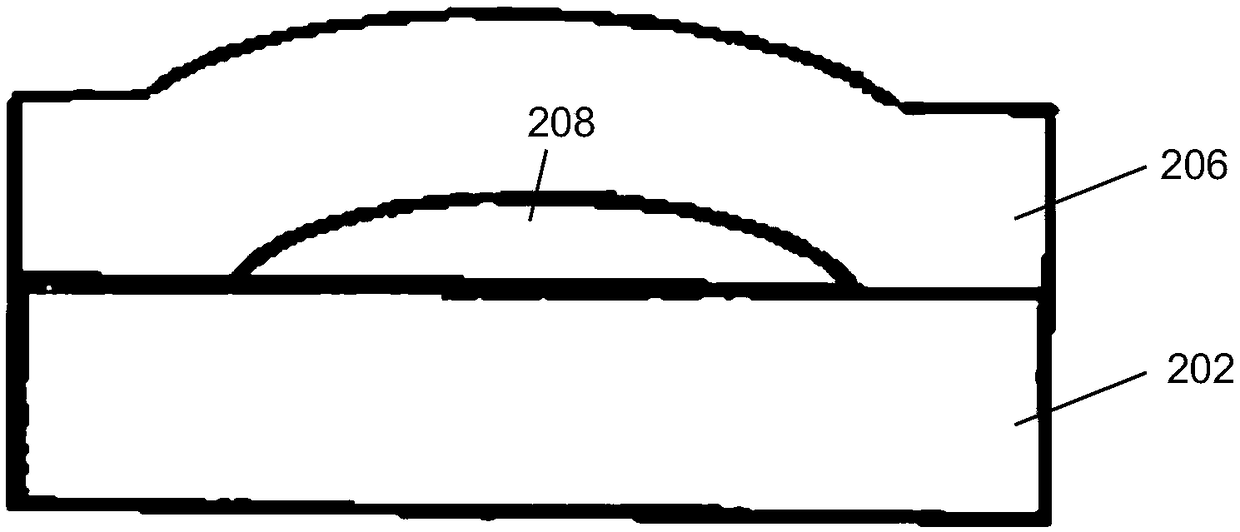

[0027] ●Looking from the appearance, the blisters on the paint surface are dense and raised, similar to pore groups. Blistered areas generally show the outline of handprints or have significant or polished wipe marks, indicating that there are obvious traces of human manipulation in defective areas.

[0028] ●Looking at the location, most of the blistering defects are locat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com