Optical characteristic measuring system and application method thereof

A technology for measuring systems and optical characteristics, applied in the field of optical testing, which can solve problems such as high demand for detector height ranges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

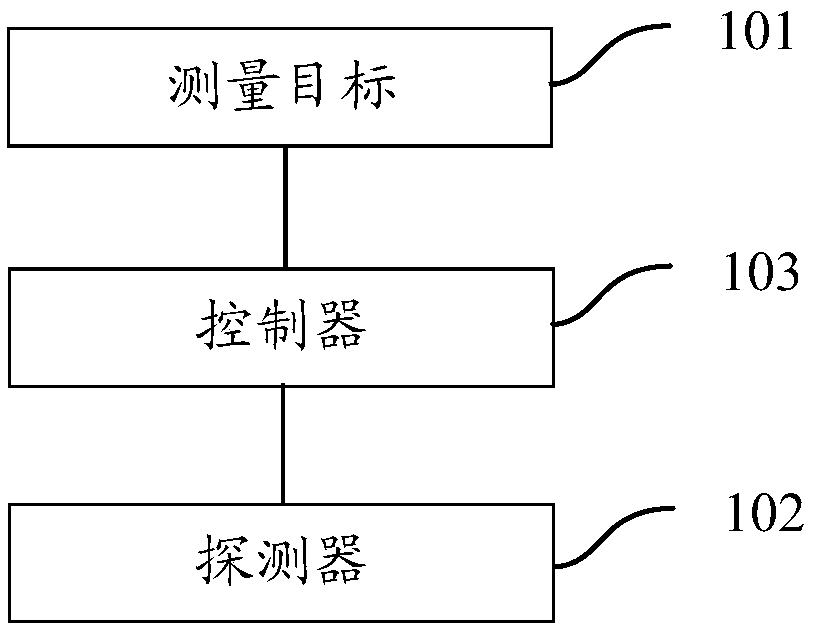

[0094] Such as figure 1 As shown, an optical characteristic measurement system provided by an embodiment of the present invention includes: a measurement target 101, a detector 102, and a controller 103; wherein,

[0095] The measurement target 101 and the detector 102 are located in the same horizontal plane;

[0096] The controller 103 is configured to receive a measurement instruction, determine the target motion posture of the measurement target 101 and the target position information of the detector 102 according to the target incident angle and target detection angle carried in the measurement command; The movement posture of the target is controlled to adjust the movement posture of the measurement target 101; according to the target position information, the detector 102 is controlled to move;

[0097] The measurement target 101 is used to adjust its own movement posture under the control of the controller 103;

[0098] The detector 103 is configured to move to a tar...

Embodiment 2

[0101] Embodiment 2 is basically the same as Embodiment 1, and the similarities will not be described in detail. The difference lies in:

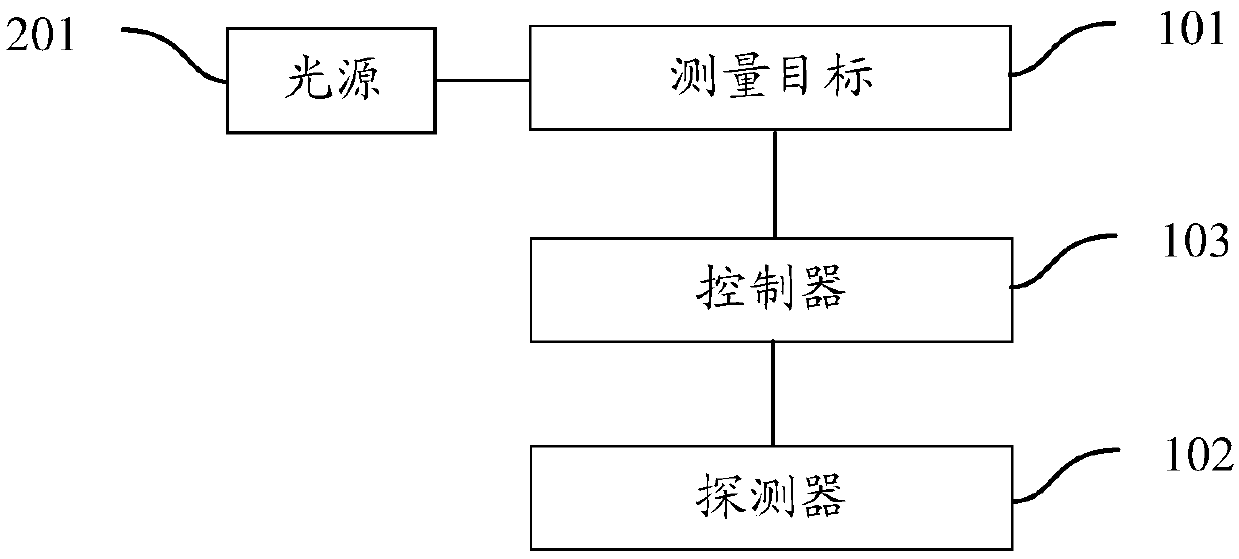

[0102] Such as figure 2 As shown, the optical characteristic measurement system may further include: a light source 201; wherein,

[0103] The light source 201, the measurement target 101 and the detector 102 are located in the same horizontal plane;

[0104] The light source 201 is configured to emit incident rays to the measurement target 101;

[0105] The detector 102 is configured to emit a detection line to the measurement target 101, and measure the measurement target 101 according to the detection line reflected by the measurement target 101;

[0106] The measurement target 101 is further configured to reflect the detection line to the detector 102 according to the detection line;

[0107]The controller 103 is configured to determine an incident azimuth angle and an incident elevation angle according to the target incident angle ...

Embodiment 3

[0114] The third embodiment is basically the same as the second embodiment, and the similarities will not be repeated. The difference lies in:

[0115] Such as Figure 7 As shown, the measurement target 101 includes: a measurement target body 1011, a central axis 1012, an upper arc motion mechanism 1013, a turning mechanism 1014 and a lower arc motion mechanism 1015; wherein,

[0116] The center of the measurement target body 1011 is connected to one end of the central axis 1012;

[0117] The other end of the central shaft 1012 is connected with the first slider in the upper arc motion mechanism 1013;

[0118] The slewing mechanism 1014 is arranged between the upper arc motion mechanism 1013 and the lower arc motion mechanism 1015;

[0119] The turning mechanism 1014 is connected with the second slide block in the lower arc movement mechanism 1015 , and the turning mechanism 1014 is connected with the upper arc movement mechanism 1013 .

[0120] Through the above settings, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com