Heat radiator used for machine room server heat radiation

A server and radiator technology, used in instruments, electrical digital data processing, digital data processing components, etc., can solve the problems of poor heat dissipation, not easy to dissipate heat, and the temperature of server heating parts cannot be lowered, and achieve rapid reduction, The heat conduction is smooth and the heat dissipation effect is obvious.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

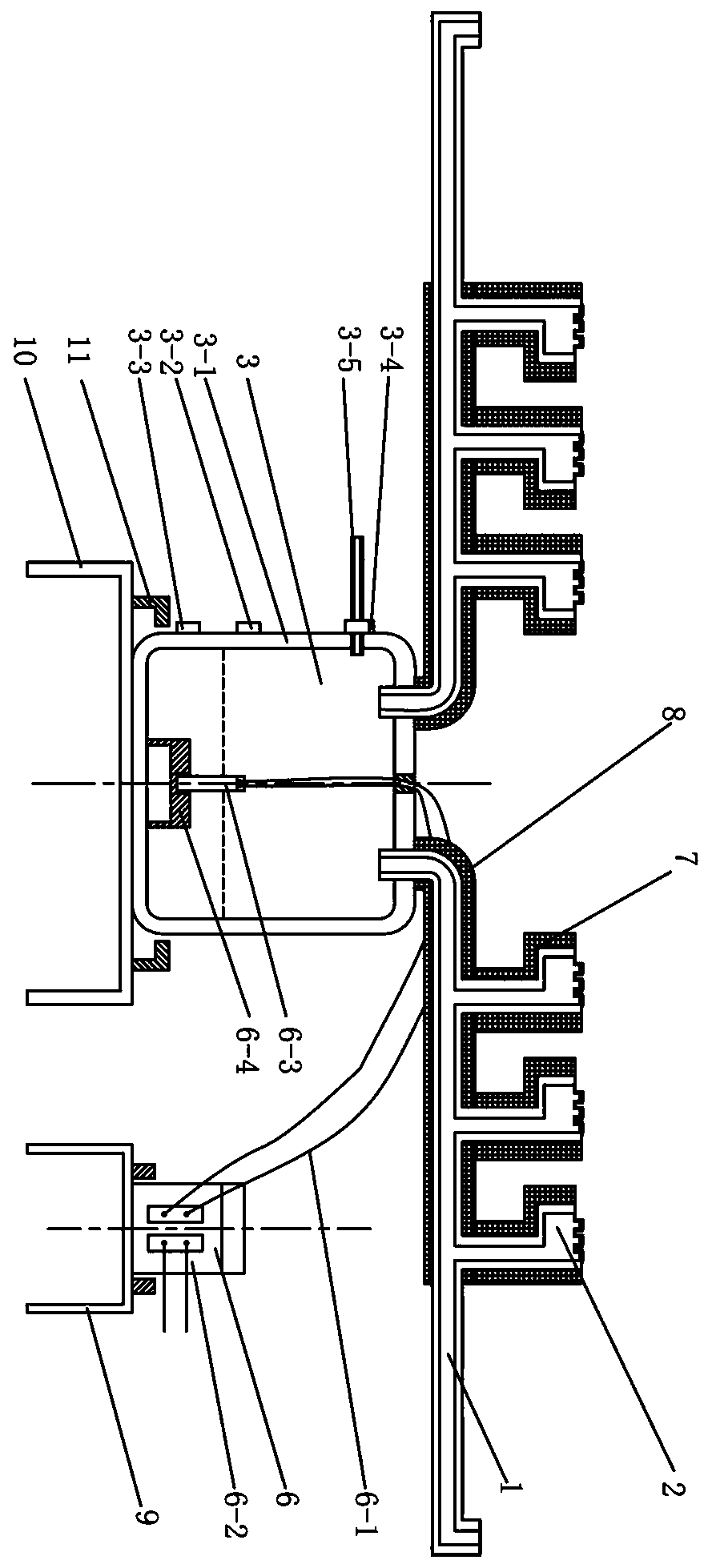

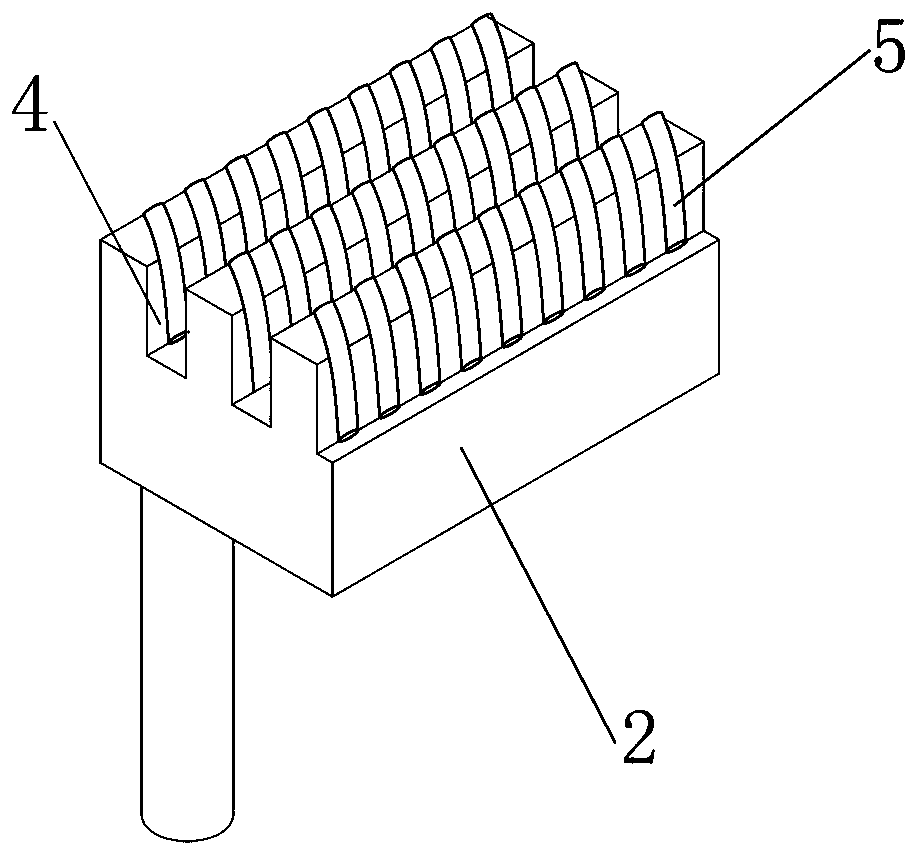

[0022] Such as Figure 1 ~ Figure 2 As shown, a radiator for server cooling in a computer room includes an air guide pipe 1, a heat sink 2 connected to a server heating component, and a liquid nitrogen heat preservation device 3. At least two guide tubes are arranged on the top of the liquid nitrogen heat preservation device 3. Air pipe 1, several heat sinks 2 are distributed side by side on each air pipe 1 at intervals, the distance between two adjacent heat sinks 2 does not exceed 4.2cm to 4.7cm, the end of the air pipe 1 extends out of the machine room, and the temperature after use The raised nitrogen gas is discharged into the outdoor atmosphere to prevent the nitrogen content in the computer room from being too high, so as to affect the safety of the staff in the computer room. conduction, heat sink 2 and server heating components are c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com