Train control system software test system and method based on event and fault record data

A train control system and fault recording technology, applied in software testing/debugging, electrical digital data processing, error detection/correction, etc., can solve problems such as poor accuracy of test results, lower product quality, and inability to save data in real time, and achieve results Strong continuity, improved test quality, and improved visibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

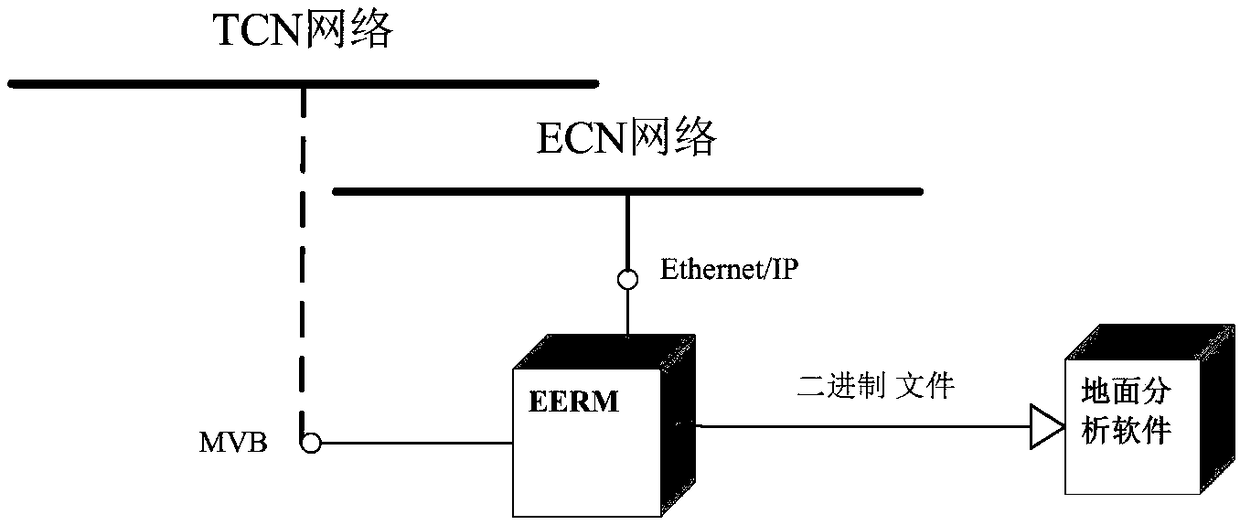

[0041] This embodiment provides a system for testing the software of the train control system based on event and fault record data, such as Figure 5 As shown, it includes the tested module, the accompanying test module, the event recording module for recording input and output data, and the PC loaded with analysis software; the tested module, the accompanying test module, and the event recording module are connected sequentially through the MVB bus; the PC The machine adopts serial port or Ethernet to connect with the test module and the module under test respectively.

[0042] The tested module is tested through the test companion module, and the real-time test results are recorded in the event record module, which is downloaded and analyzed by a PC loaded with analysis software, and the test results are reliable and accurate.

Embodiment 2

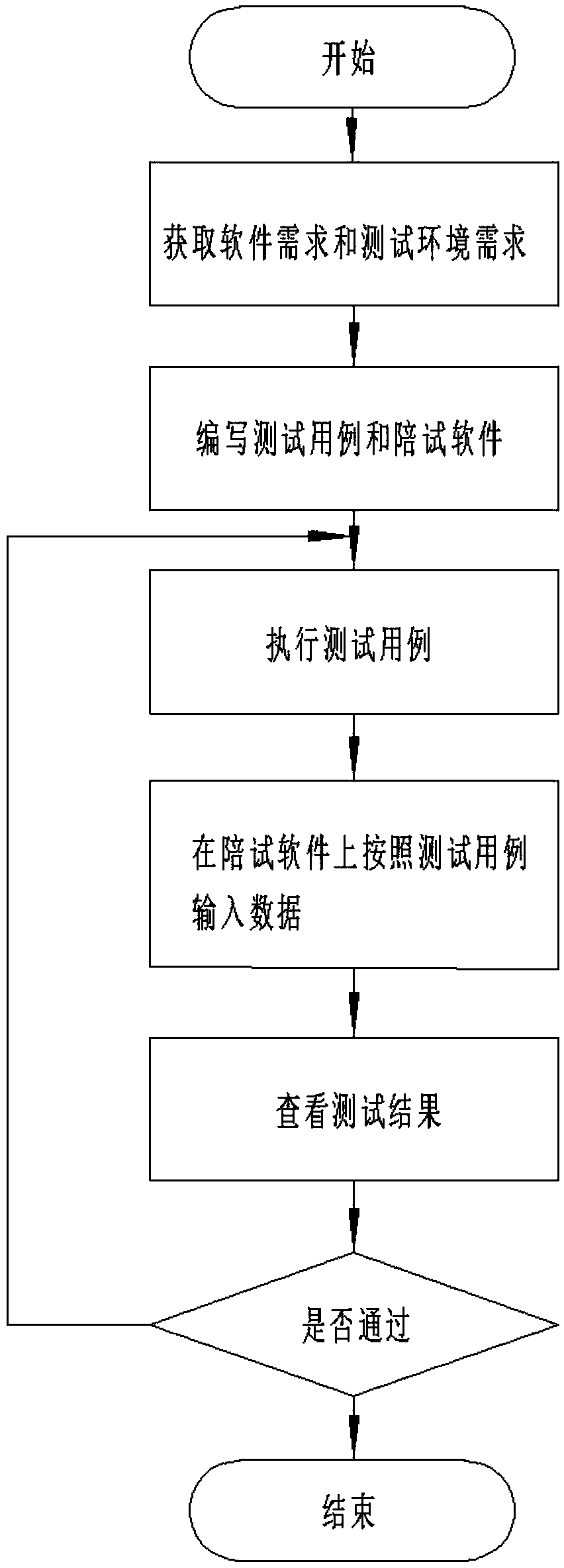

[0044] Such as figure 1 As shown, in the existing test method, after inputting data according to the test case on the accompanying test software, the test result can only be viewed through the method of display and monitoring variables, which cannot save data in real time and has poor accuracy (such as display The displayed speed can reach up to 0.1s), while the human eye and reaction time cannot reach the millisecond level and are prone to fatigue, and the accuracy of the test results is poor. This method of observing results has poor real-time performance, lack of continuity in data, and cannot know the analysis process, nor can it judge the error situation in the test process. When testing some control function points, it is easy to cause errors and reveal defects to the site, which reduces the quality of the product.

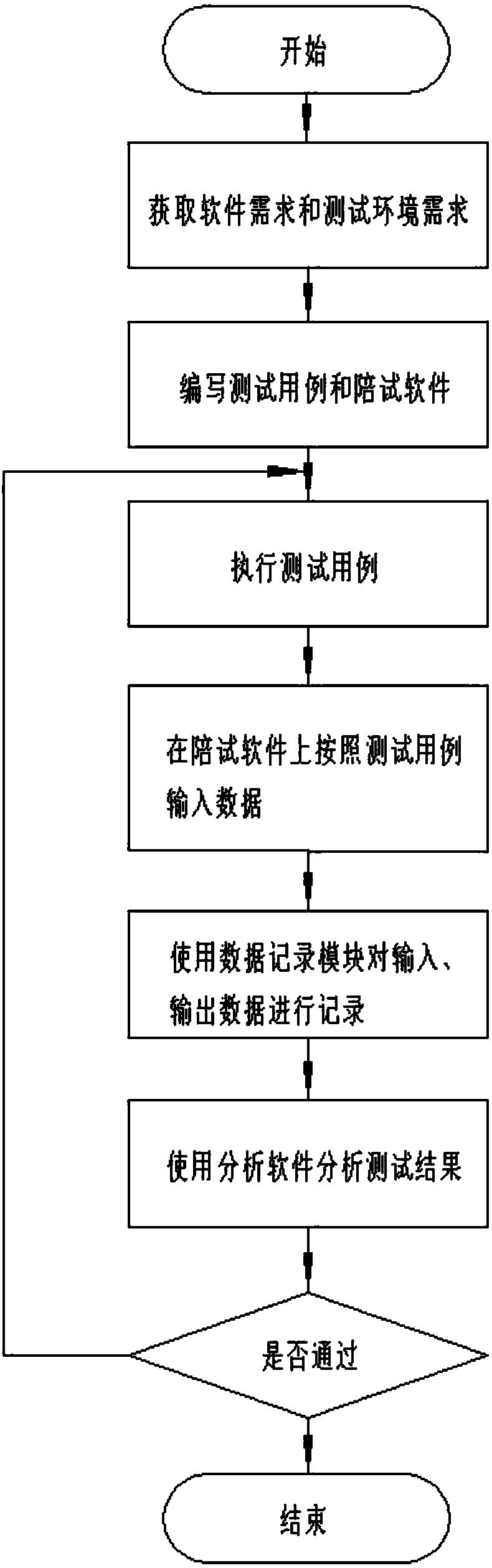

[0045] Such as image 3 and Figure 4 As shown, the present embodiment provides a method for testing the train control system software based on event and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com