Oil casing shaft casing damage image feature pattern recognition method

An image feature and pattern recognition technology, applied in character and pattern recognition, image analysis, image data processing, etc., can solve problems such as unpublished technology, no reference and improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

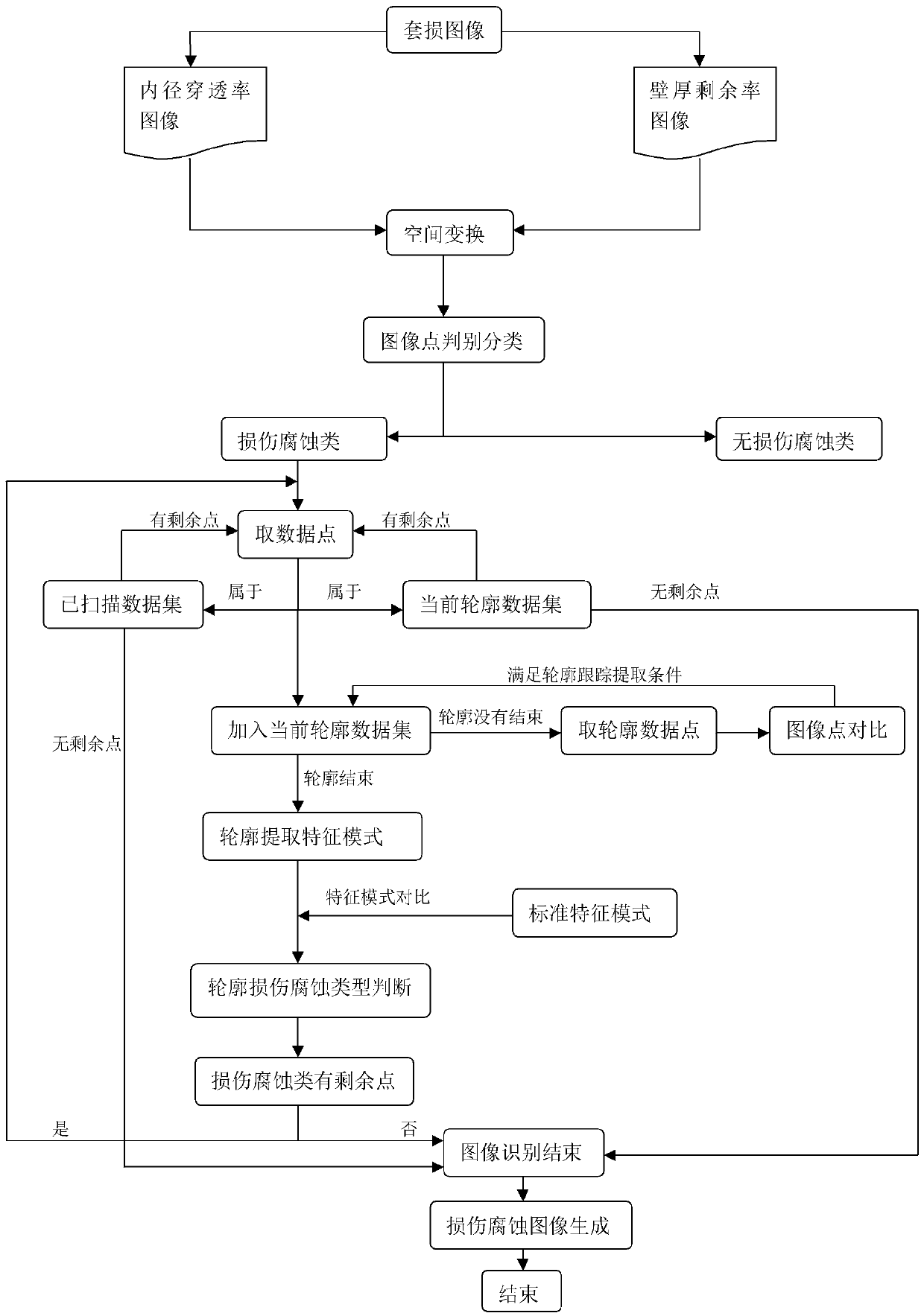

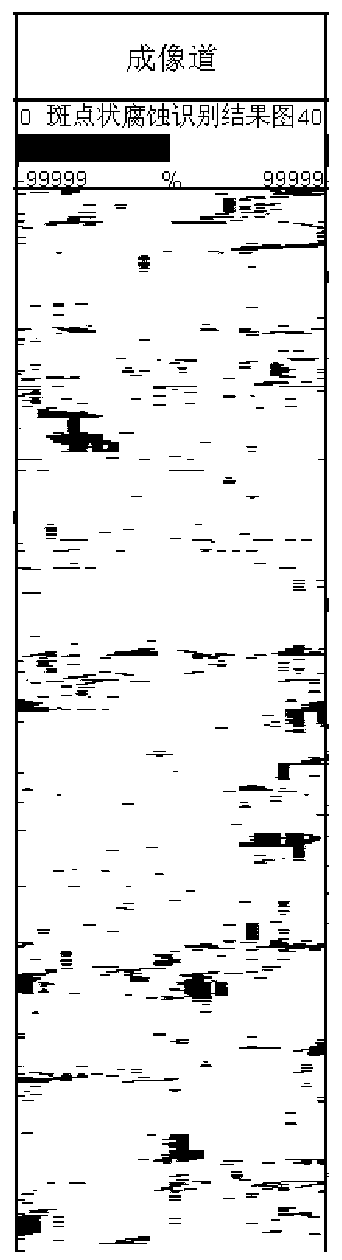

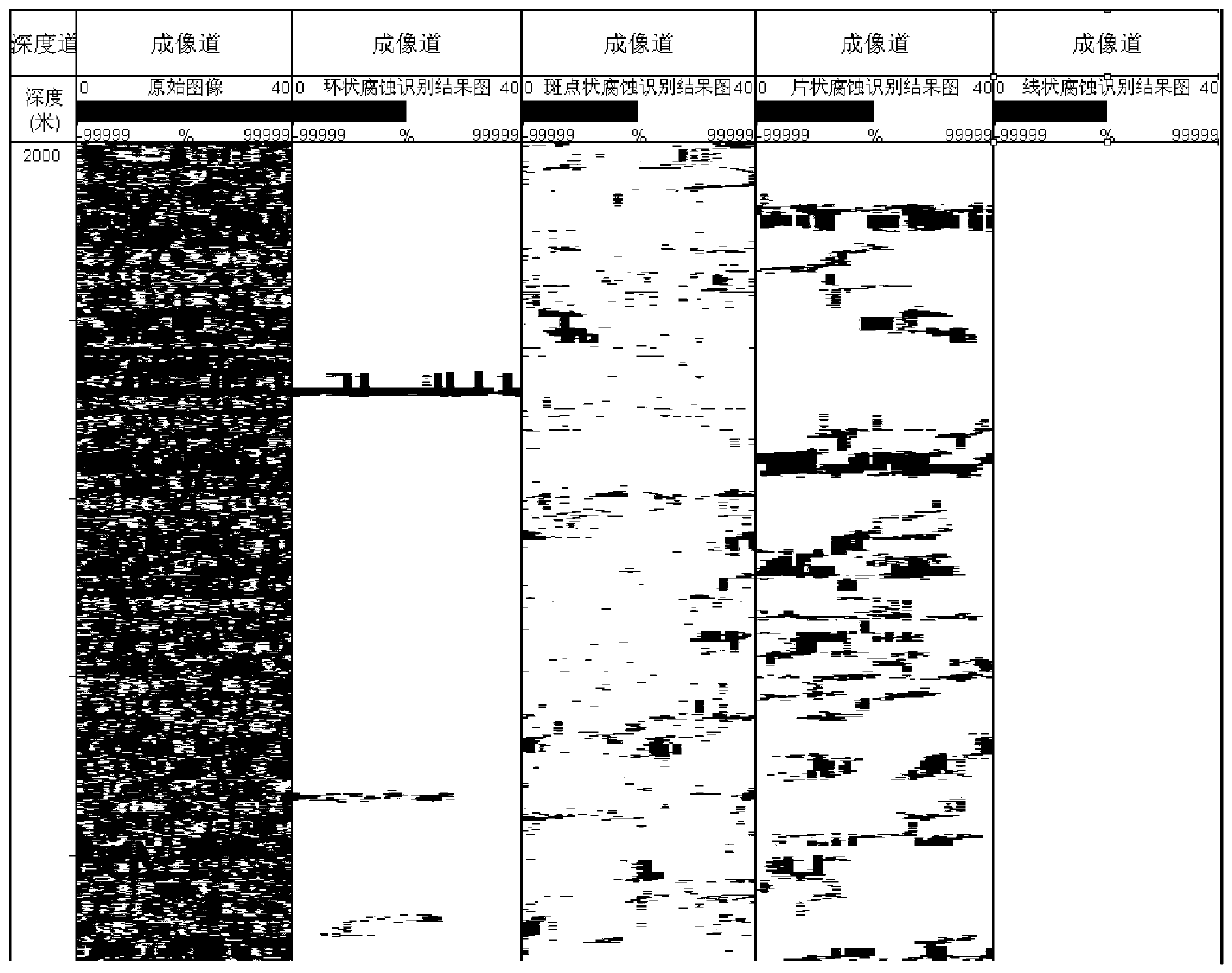

[0143] Figure 10 It shows the results of pattern recognition of damage and corrosion characteristics on the inner diameter penetration rate image of the oil casing of a multi-arm borehole caliper imaging logging tool for a certain well using the method of the present invention. The depth sampling interval of the original logging data corresponding to the inner diameter penetration rate image of the tubing and casing in this well is 0.003048 meters, and the multi-arm caliper imaging logging tool has 40 measuring arms. According to the actual casing situation of this well and the thinking of the present invention, define four kinds of damage corrosion type classification standards, that is, the standard characteristic mode is as follows,

[0144] Annular corrosion: the radial direction is greater than 50% of the circumference of the casing, and the axial direction is less than 2 times the inner diameter of the tubing;

[0145] Linear corrosion: the radial direction is less tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com