Steel structure engineering capital early warning management system based on BIM (Building Information Modeling)

A management system and steel structure technology, which is applied in the field of BIM-based steel structure project fund early warning management system, can solve the problems of backward management of accounts receivable, failure of analysis precision to meet the comparison requirements, and increase of bad debts. Achieve the effect of saving manpower, material and time resources, avoiding unreasonable production and operation activities, and changing cumbersome and complicated methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing.

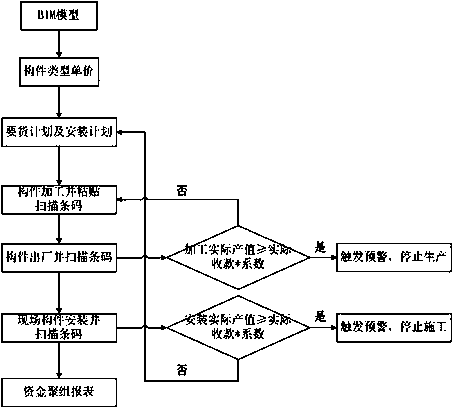

[0028] Such as figure 1 As shown, a BIM-based steel structure engineering fund early warning management system includes a data input module, a data acquisition module, a financial statistics module, a central processing module, an intelligent early warning module and a data display module;

[0029] The data input module is used to provide BIM model and engineering basic metadata entry, including basic data of BIM model components, comprehensive unit price for processing and installation of different component types, the comprehensive unit price is calculated based on weight, and according to the implementation stage goals, The purchase plan and installation plan data formulated on the provided BIM model, the data is associated and matched to the corresponding components of the BIM model through virtual mapping technology;

[0030] The data acquisition module is used for th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com