Temperature compensation based charging control and protection method for nickel-hydrogen battery pack

A nickel-metal hydride battery, temperature compensation technology, applied in battery circuit device, safety/protection battery circuit, arrangement of multiple synchronous batteries, etc. Guarantee normal use, simple and feasible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

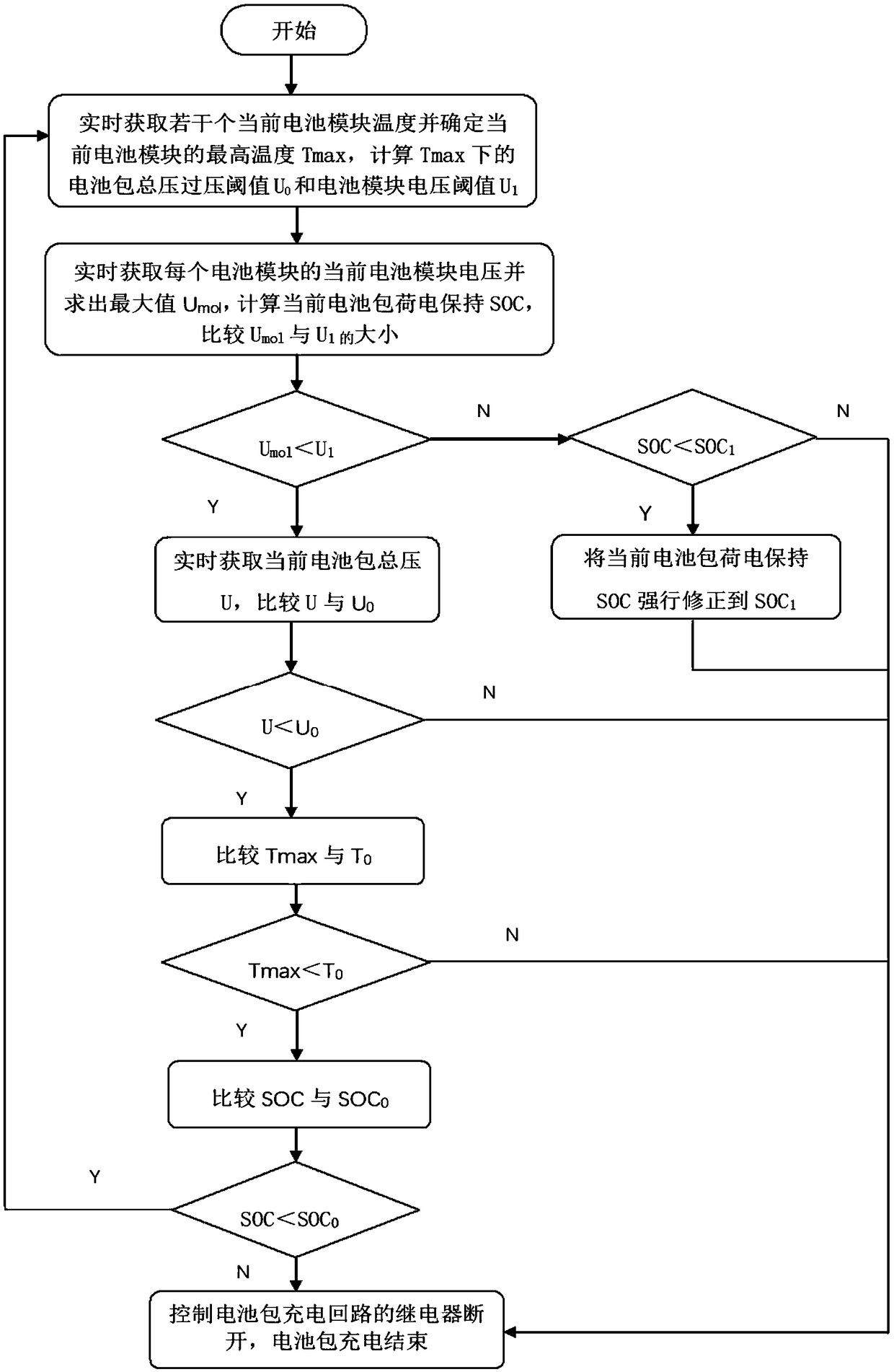

[0026] A charging control and protection method for Ni-MH battery pack based on temperature compensation, the process control diagram is as follows figure 1 As shown, the battery pack includes a number of battery modules connected in series, and the battery module includes a number of single batteries connected in series. The steps are as follows:

[0027] S1: Obtain the temperature of several current battery modules in real time and determine the maximum temperature Tmax of the current battery module, and calculate the total voltage overvoltage threshold U of the battery pack at the maximum temperature Tmax 0 and battery module voltage threshold U 1 , then execute step S2;

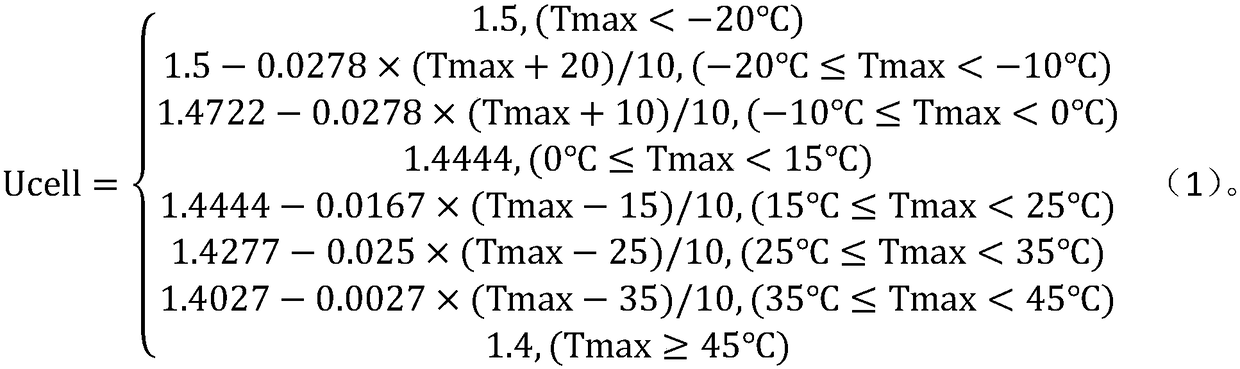

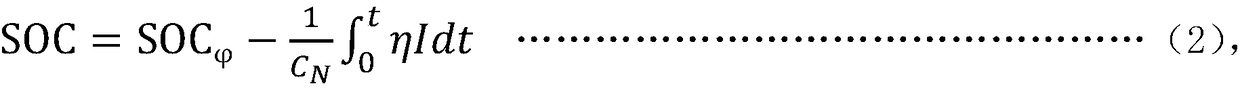

[0028] The battery module voltage threshold U at the highest temperature Tmax of the battery module 1 is N×Ucell, where N is the number of single cells in the battery module, and Ucell is the voltage threshold of a single cell fully charged at the highest temperature Tmax of the battery module, and Ucel...

Embodiment 2

[0039] A temperature compensation-based charging control and protection method for Ni-MH battery packs, the steps of which are basically the same as those of the temperature-compensated Ni-MH battery pack charging control and protection method in Embodiment 1, except that in step S2, The current battery pack charge maintains SOC at a rate of 3% / second and is revised to SOC 1 ; In step S4, the battery module maximum temperature threshold T 0 The value is 60°C; in step S5, the battery pack is charged with the highest charge retention threshold SOC 0 The value is 95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com