Yarn stripe cloth, shoe pads, manufacturing method of yarn stripe cloth, and manufacturing method of shoe pads

A production method and threaded cloth technology, applied in insoles, footwear, clothing, etc., can solve problems such as poor shape retention, troublesome insole production, poor air permeability of soles, etc., achieve good ventilation effect, improve ventilation effect, thickness and hardness adjustable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to further explain the technical solution of the present invention, it will be described in detail below in conjunction with the accompanying drawings.

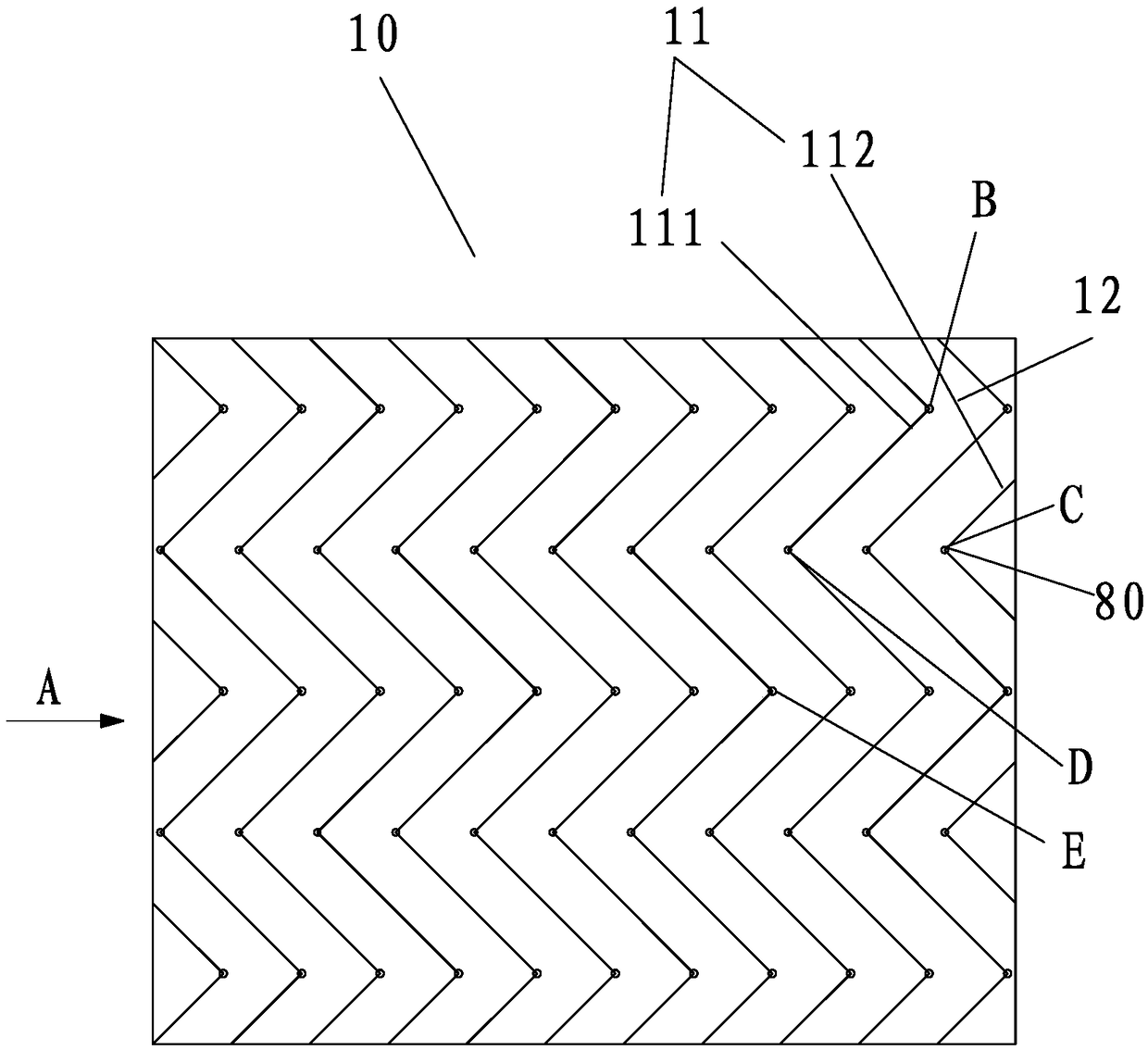

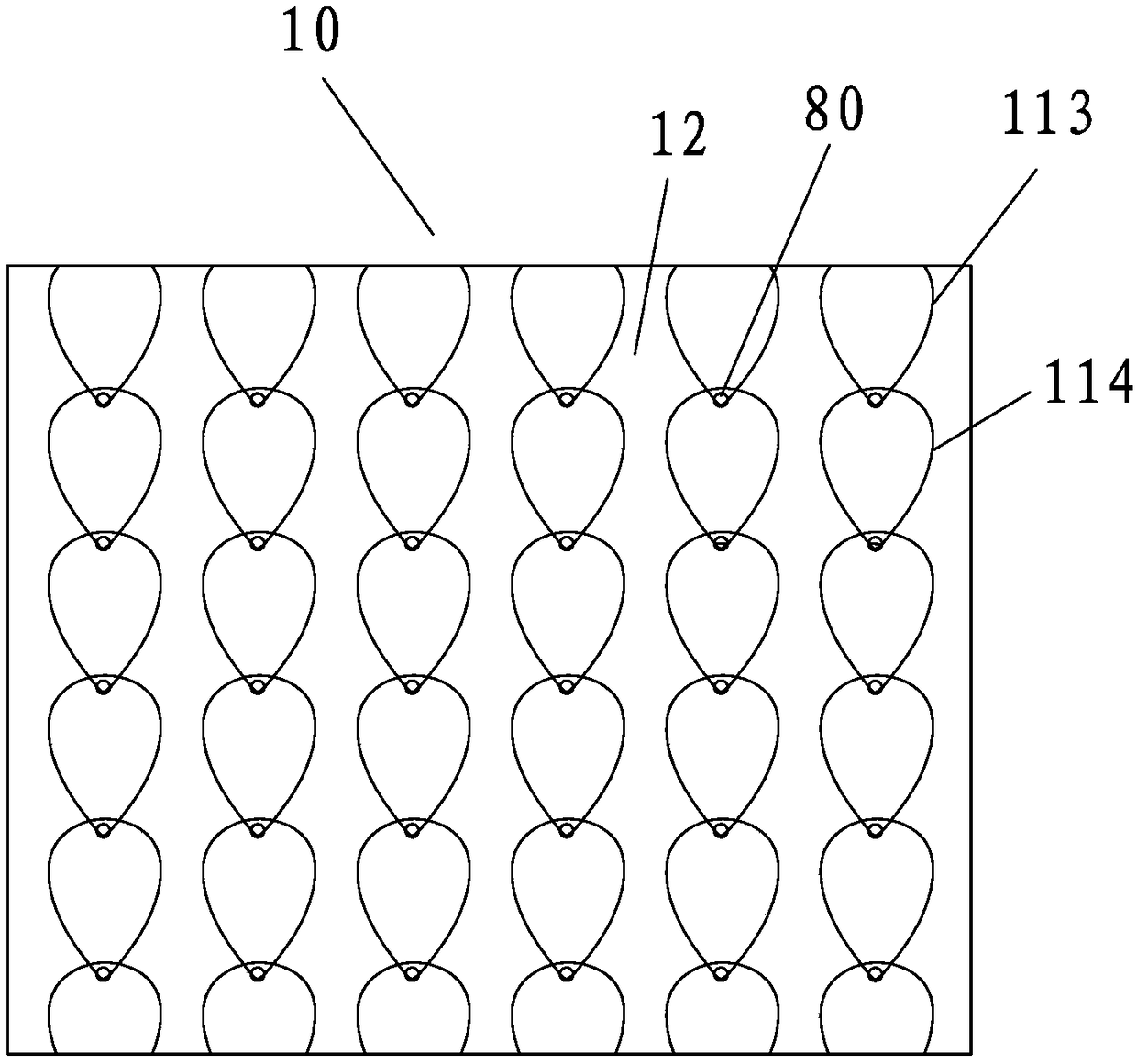

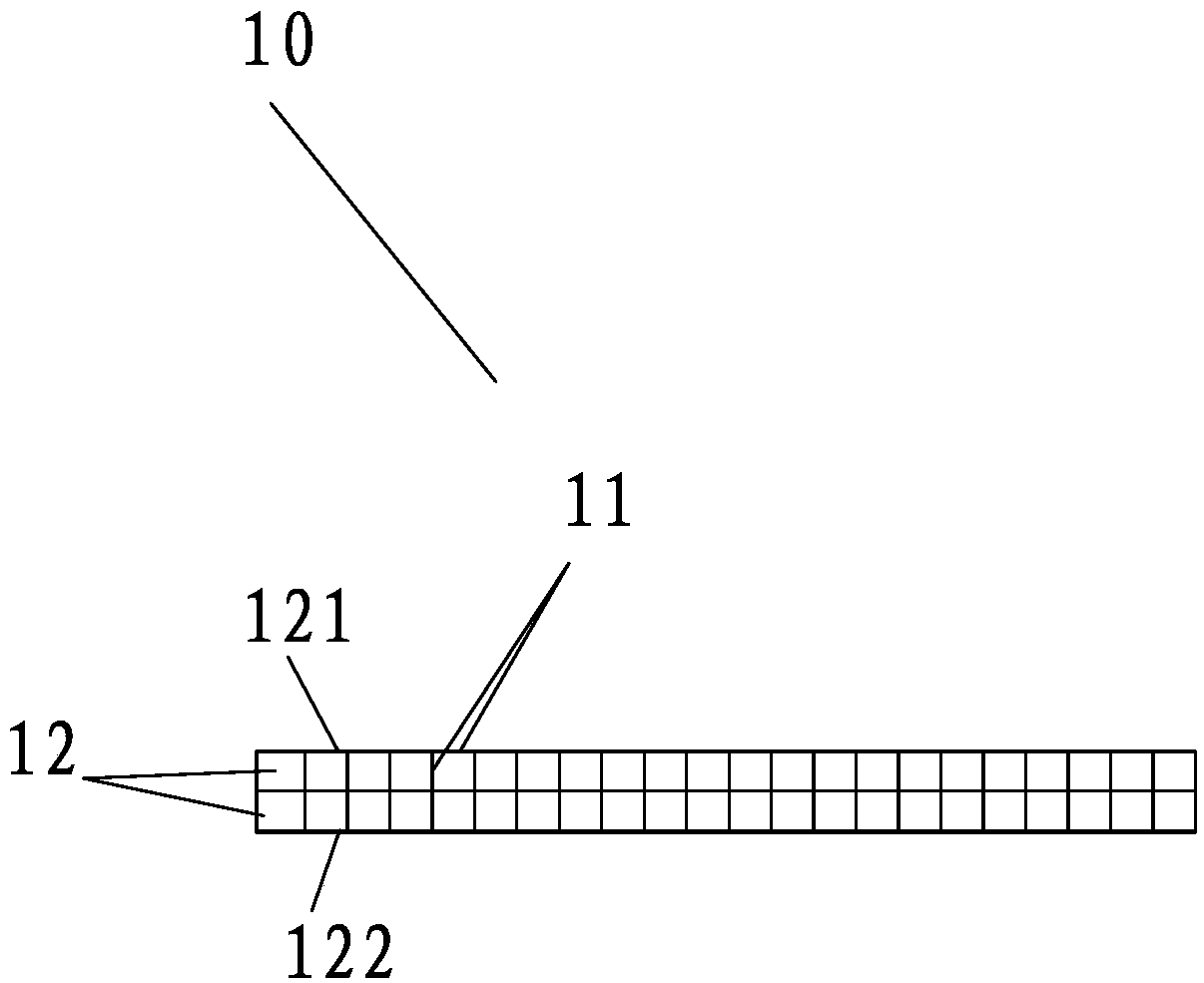

[0048] refer to Figure 1 to Figure 10 , threaded cloth 10, including a pad body 12 and a plurality of yarns woven on the pad body 12, the thickness and hardness of the pad body 12 can be selected according to the design requirements of the threaded cloth 10, and the pad body 12 is selected to have certain flexibility Pad body, to ensure that the knitting needles can pierce the pad body 12 under normal working conditions, the pad body 12 has a first surface 121 and a second surface 122 oppositely arranged, and the first surface 121 and the second surface 122 are threaded cloth 10 when placed flat on the upper surface and the lower surface, the pad body 12 is provided with a plurality of through holes 80 (for the convenience of viewing, the figure is not drawn according to the actual scale), and the through hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com