A welding method for q500qe high-strength bridge steel corner joints

A welding method and high-strength technology, applied in the field of steel bridge manufacturing, can solve the problems of high-strength steel cold straightening, affecting the service life of fatigue, and small deformation of plate units after welding, so as to ensure the welding quality easily, solve welding deformation, Effect of Welding Defect Reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

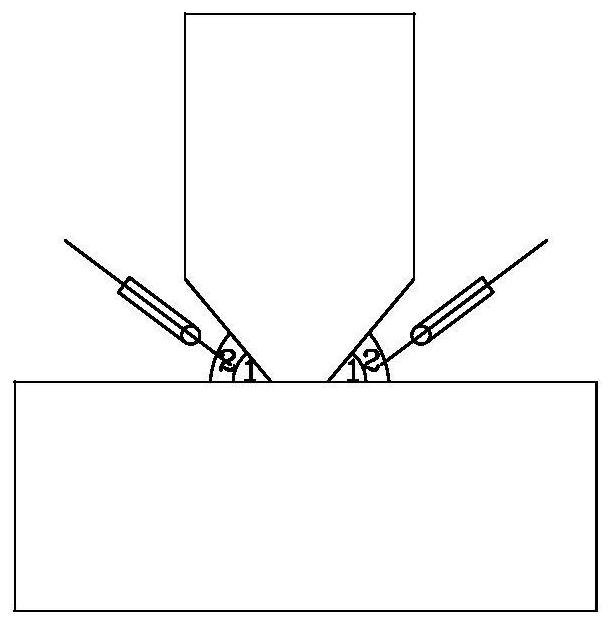

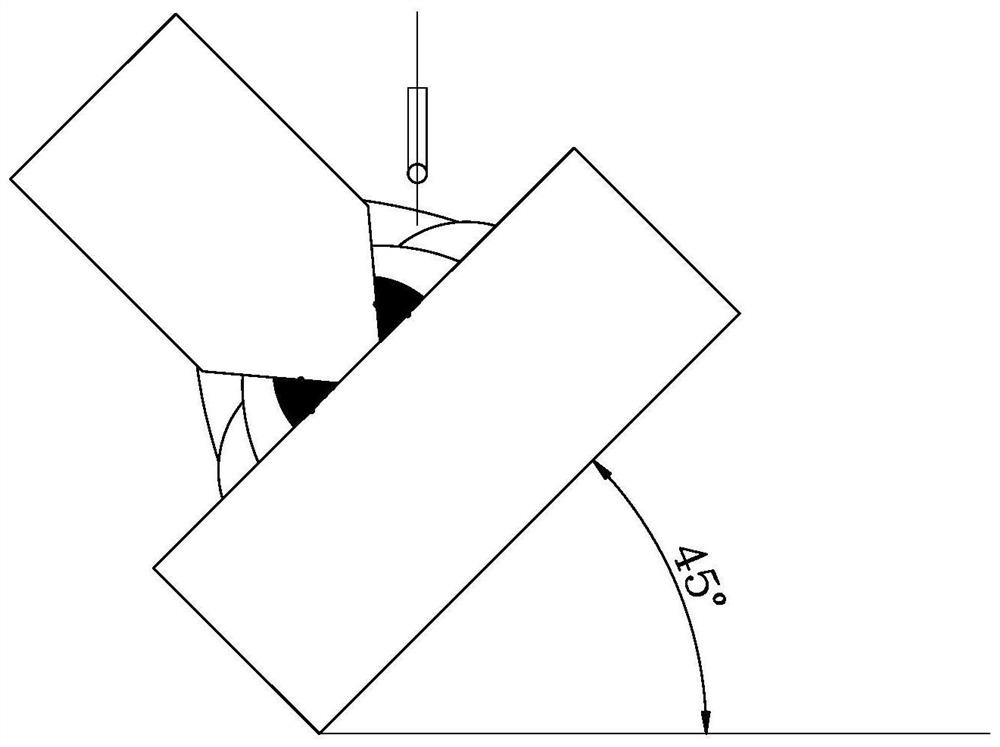

[0019] Attached below figure 1 , 2 , 3 and specific embodiments The present invention will be described in further detail.

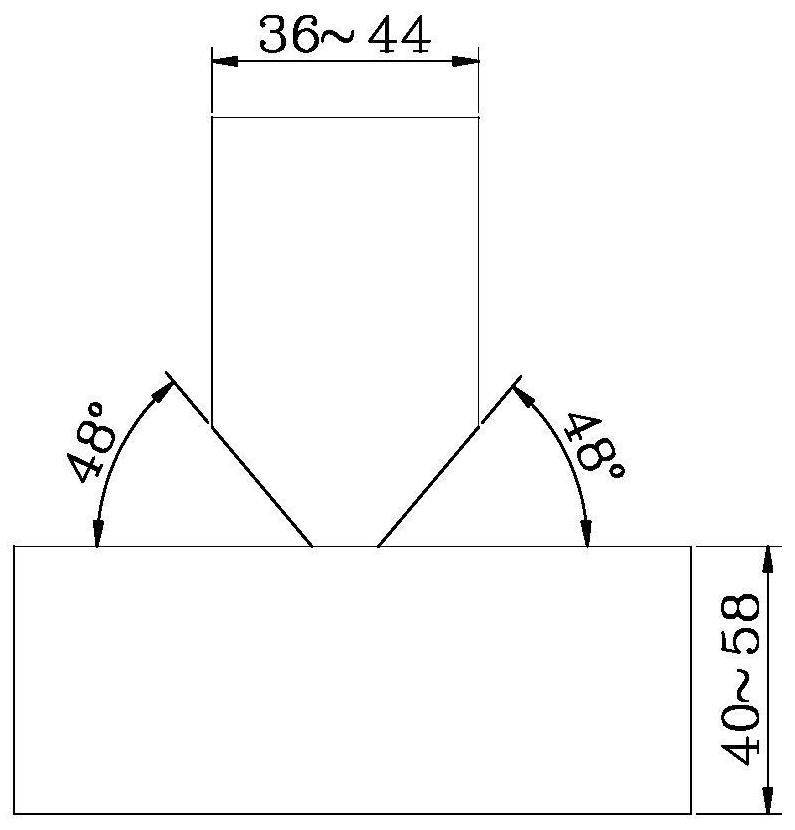

[0020] 1) Welding base metal: the thickness of the bottom plate is 40-58mm, and the thickness of the ribs (stiffeners) is 36-44mm; the bottom plate and the ribs are both Q500qE high-strength bridge steel, and their longitudinal and transverse tensile strengths are 659-730MPa , the longitudinal and transverse yield strengths are 528-573MPa, the elongation is 20.5%-26%, the low-temperature impact (-40°C) is 232-300J, and the shear section rate (-40°C) is 90%-100%;

[0021] 2) Welding groove: Partial penetration double-sided symmetrical grooves are opened on both sides of the ribs, and the groove angle is 48°. The double-sided groove angle of the existing partial penetration weld is 45° or 50°. When the 45° groove is used for welding, penetration is easy to occur, that is, incomplete fusion occurs at the weld root. 50° groove is used, because the plate i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com