Welding device for metalworking practice teaching of college students

A metalworking practice and welding device technology, applied in auxiliary devices, teaching models, educational appliances, etc., can solve problems such as low safety, increased welding difficulty for workpieces, and inability to effectively exercise students' practical ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

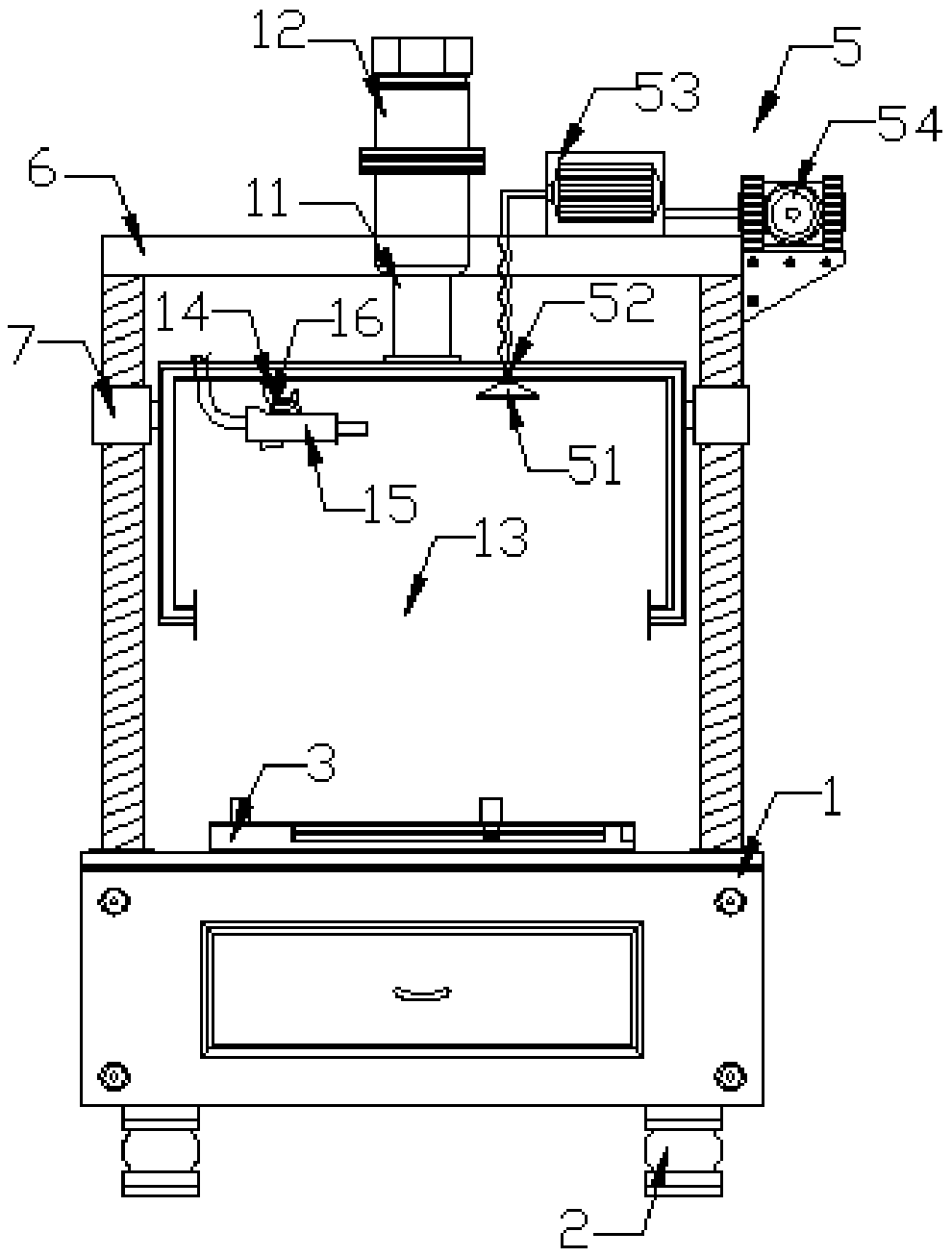

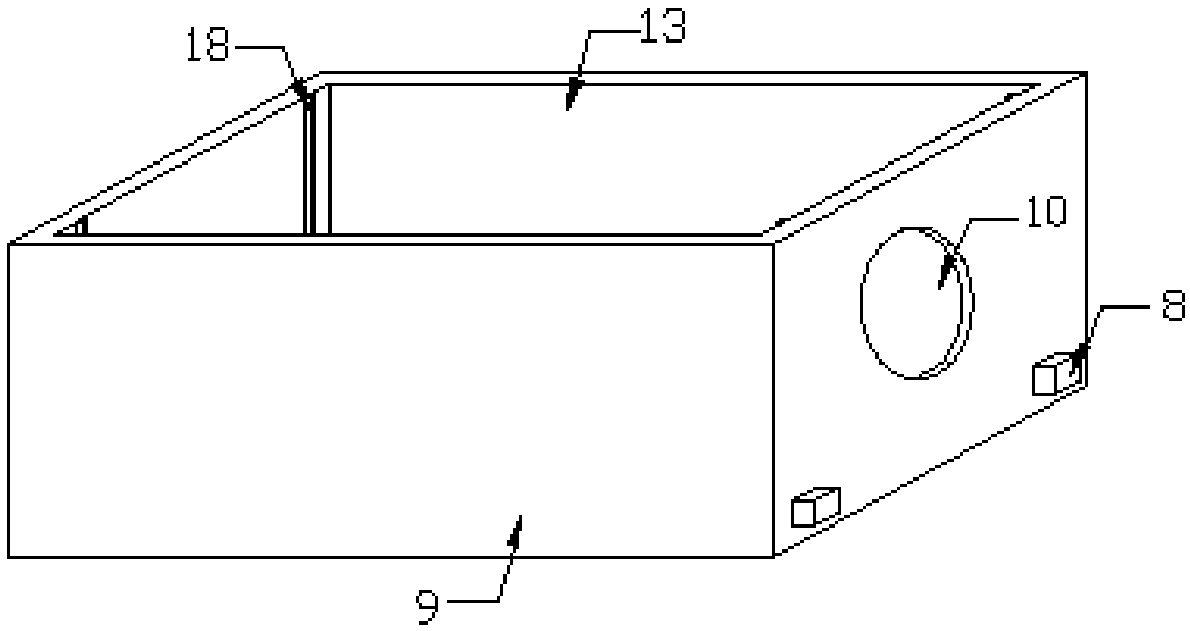

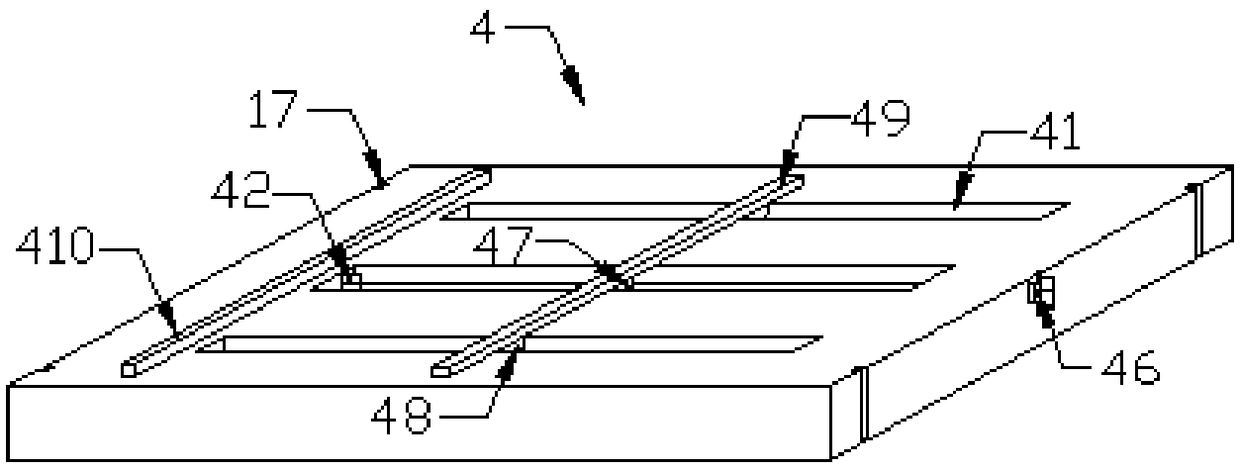

[0022] Such as Figure 1-5 As shown, this specific embodiment adopts the following technical solutions: a welding device for metalworking practice teaching for college students, including a bearing base 1, a shock absorber 2, a welding console 3, a workpiece fixing mechanism 4, a welding exhaust gas treatment device 5, a machine frame 6, sliding sleeve 7, connector 8, transparent protective cover 9 and telescopic cylinder 12, the bottom of the bearing base 1 is fixedly equipped with a shock absorber 2, and the shock absorber 2 is provided with four, and the bearing base 1 is fixedly installed with a welding console 3, the welding console 3 is provided with a workpiece fixing mechanism 4, and the supporting base 1 on the opposite side of the welding console 3 is fixedly installed with a frame 6, and the welding operation A welding tail gas treatment device 5 is installed on the frame 6 at the top of the platform 3, a sliding sleeve 7 is set on the frame 6, and a connecting piec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com