Automatic feeding machine

An automatic feeding and automatic technology, which is applied in the direction of grinding feed movement, grinding machine parts, metal processing equipment, etc., can solve the problems of low efficiency of manual operation, failure to meet production requirements, high production cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to fully understand the technical content of the present invention, the technical solution of the present invention will be further introduced and illustrated below in conjunction with schematic diagrams, but is not limited thereto.

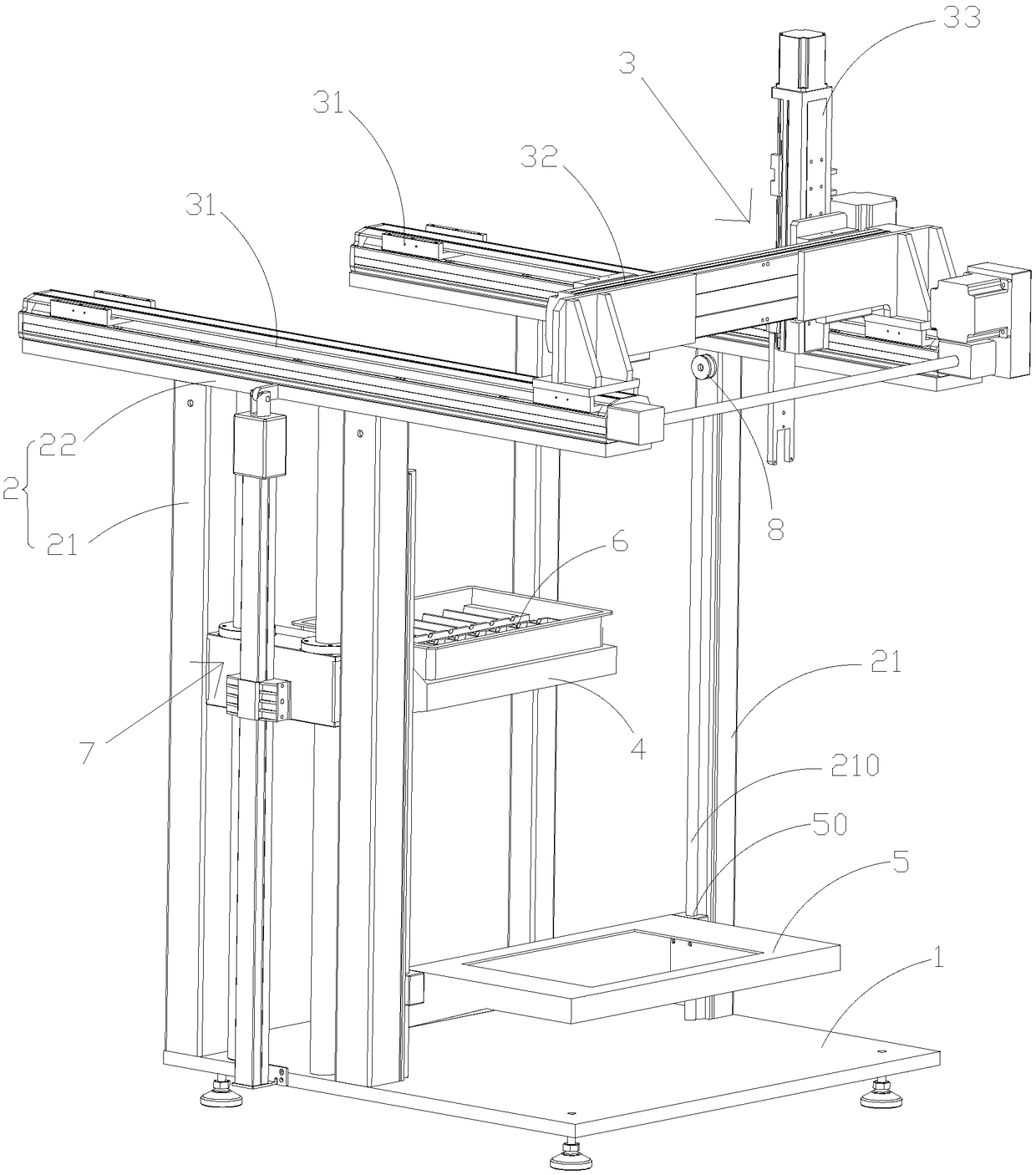

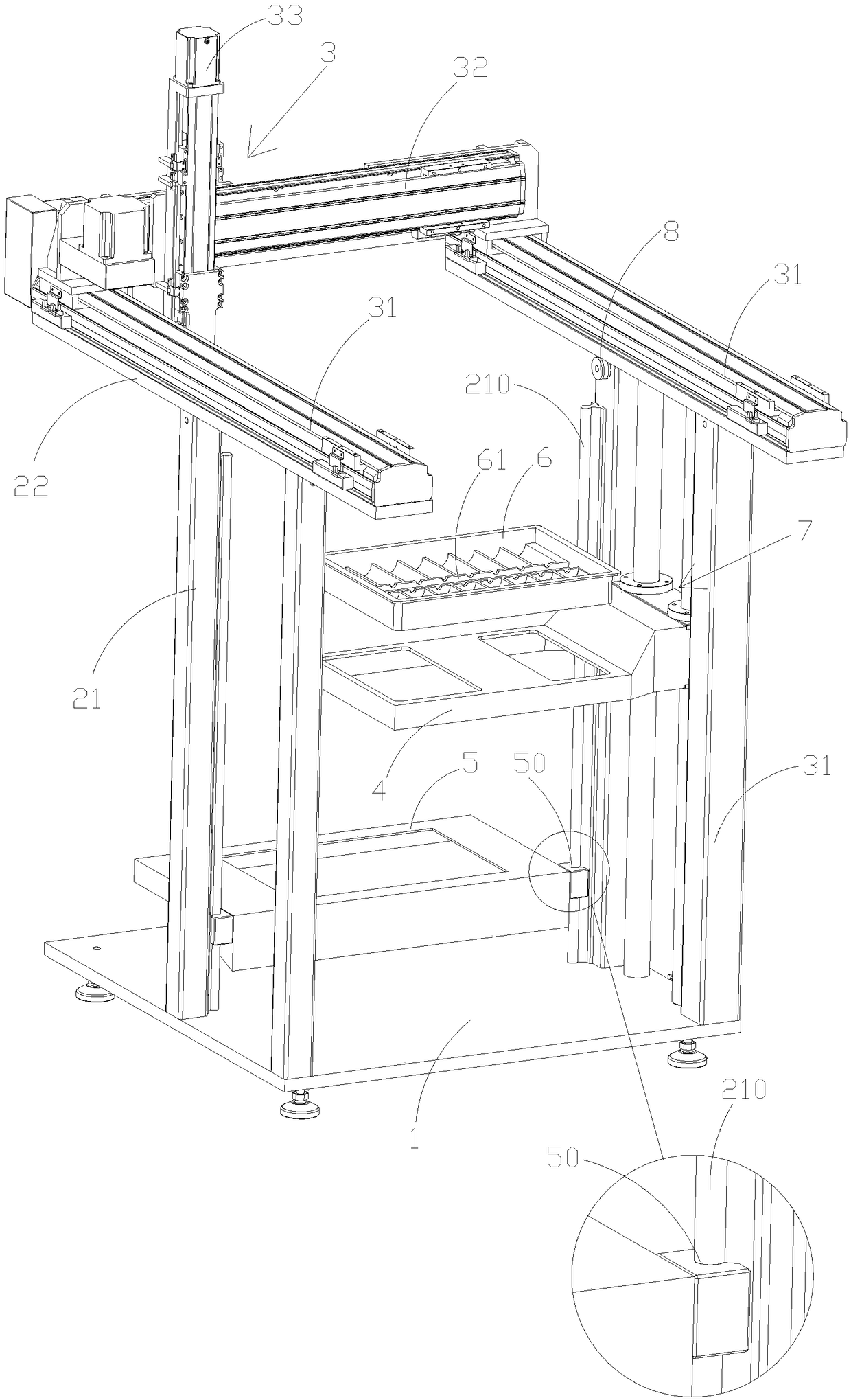

[0019] Such as figure 1 and figure 2 As shown, in this application, the automatic loading machine includes a base plate 1, two supporting devices 2, a three-axis servo mechanism 3, a material bracket 4, an empty tray bracket 5 and a control cabinet (not shown in the figure) , the bottom plate 1 is arranged at the bottom of the automatic feeding machine, which is usually made of metal material or wood; the two supporting devices 2 are respectively vertically fixed on both sides of the bottom plate 1, which are generally made of metal materials; the three-axis servo The mechanism 3 includes two X-axis 31, a Y-axis 32 and a Z-axis 33, the two X-axis 31 are respectively fixed on the upper ends of the two supporting devices 2, the Y-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com