Clamping fixture of displacement sensor

A displacement sensor and clamping tooling technology, applied in workpiece clamping devices, manufacturing tools, etc., can solve the problem of inconvenient adjustment of the displacement sensor, and achieve the effects of quick disassembly, reliable tooling, and improved measurement efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to further understand the present invention, the patent of the present invention will be further described in detail below in conjunction with the accompanying drawings, but it should not be understood that the scope of the above-mentioned subject of the patent of the present invention is limited to the above-mentioned embodiments.

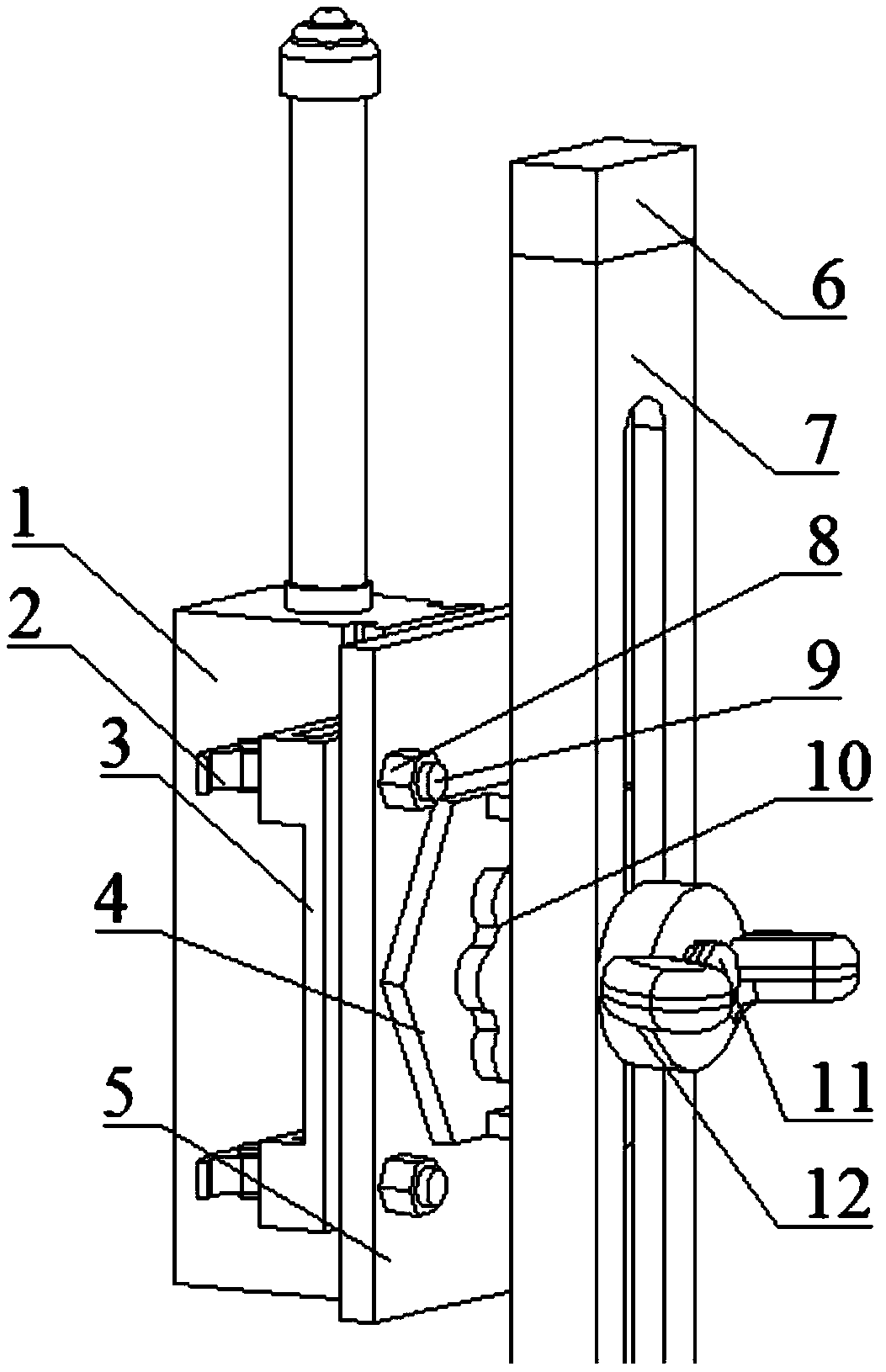

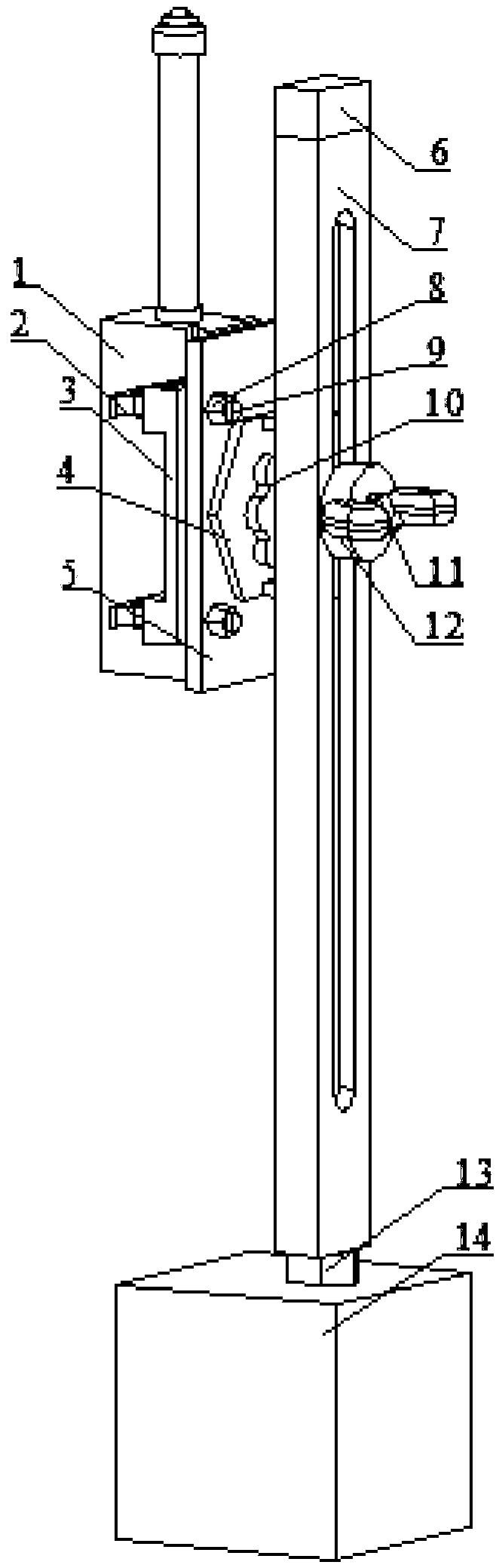

[0034] combined with figure 1 And attached Figure 5 , the displacement sensor 1 is an electronic component wrapped inside a metal casing, and there are slots on both sides of the metal casing, which are used to set the displacement sensor 1 in the U-shaped structure of the fixed block 3, and the cam wrench 2 and the rubber washer 15 are used to place the displacement sensor 1 The U-shaped structure is fixed and locked. When it is necessary to replace different sensors, the cam wrench 2 is loosened, and the metal shell is taken out from the U-shaped structure of the fixing block 3 .

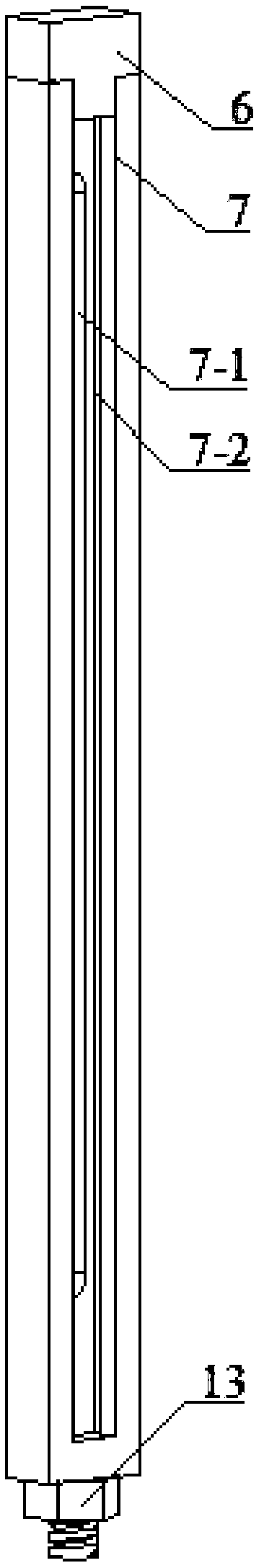

[0035] combined with figure 2 , 3 , 4 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com