Integral fan blade de-weighting scissors

A technology of fan blades and scissors, applied in the field of deduplication scissors for fan blades of the whole machine, can solve the problems of low service life, complex structure, low cutting efficiency, etc., and achieve the effects of reducing labor costs, high production efficiency requirements, and smooth hand feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

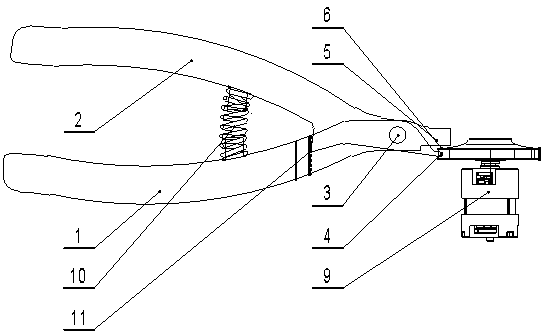

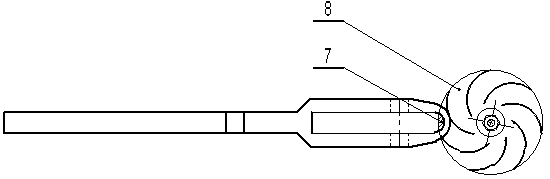

[0017] Such as figure 1 The fan blade weight removal scissors of the whole machine are shown, including the lower handle 1, the upper handle 2, the lever shaft 3, the lower jaw of the scissors mouth 4, the upper jaw of the scissors mouth 5, the blade to be cut 6, the cutting area of the blade 7, and the whole fan blade 8. Fan blade drive motor 9, return spring 10, limit stopper 11, raised part 12, the front section of the upper handle 2 and the lower handle 1 is connected by the lever shaft 3, the upper handle 2 and the lower handle 1 are connected A return spring 10 is provided, the front part of the lower handle 1 is provided with a limit stopper 11, and the front part of the upper handle 2 is provided with a raised part 12, and the raised part 12 corresponds to the limit stopper 11 up and down. The front end of the upper handle 2 is provided with a scissor-mouth jaw 4, and the lower handle 2 is provided with a scissor-mouth upper jaw 5 at the front end. The scissor blade...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com