Pushing type wooden board cutting device for construction

A cutting device and push-type technology, applied in the direction of feeding devices, sawing components, sawing equipment, etc., to achieve the effect of preventing accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

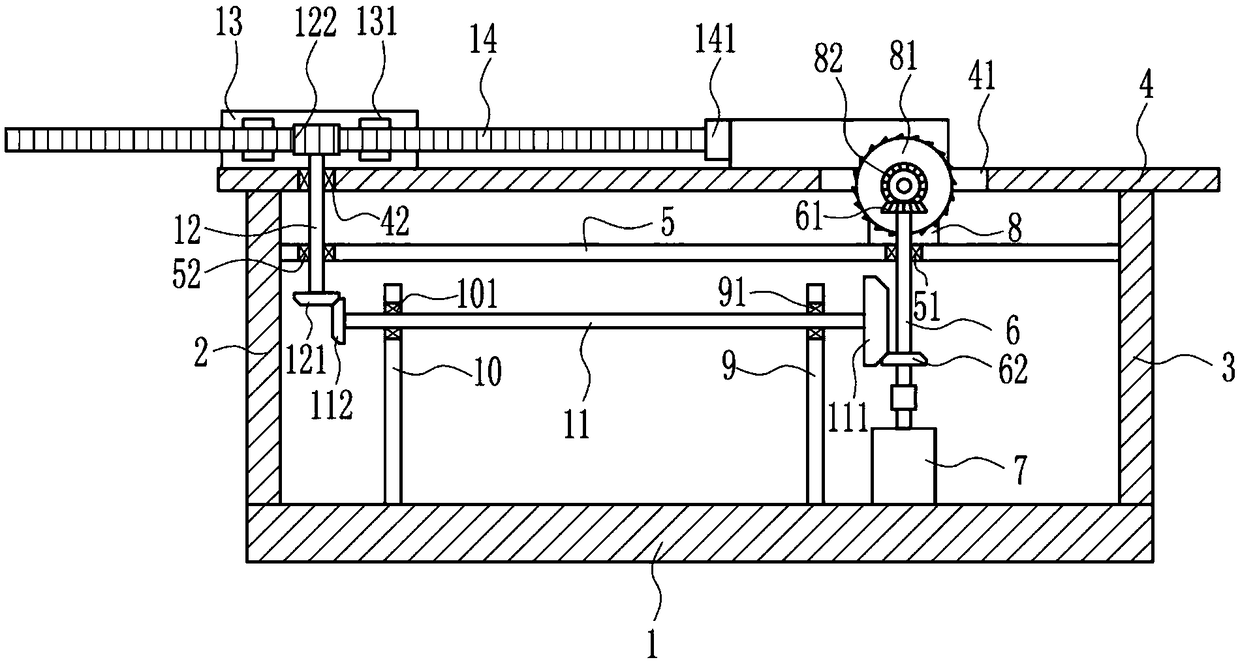

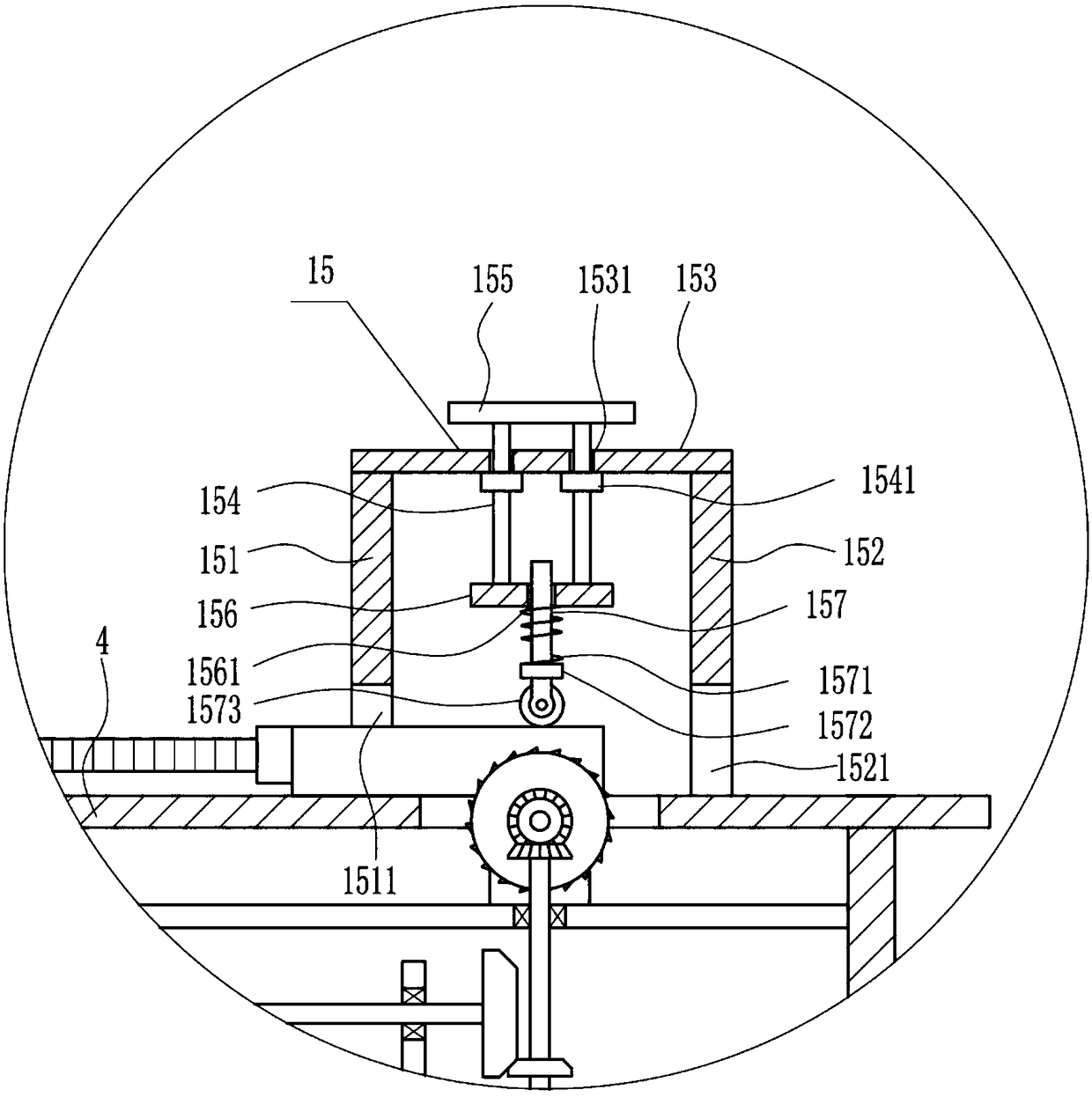

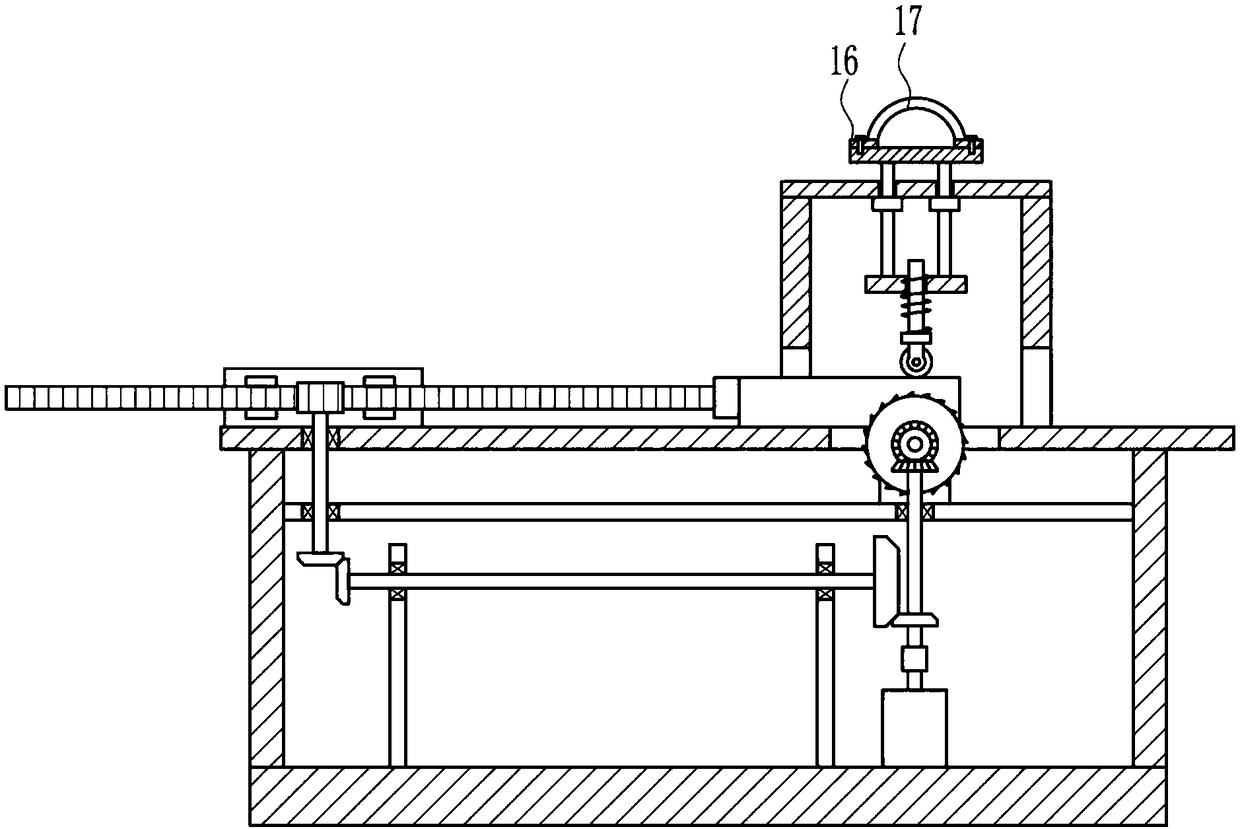

[0017] A push-type plank cutting device for construction, such as Figure 1-3 As shown, it includes a base 1, a first support 2, a second support 3, a workbench 4, a first bearing 42, a third support 5, a second bearing 51, a third bearing 52, a first shaft 6, a first Bevel gear 61, second bevel gear 62, motor 7, mounting plate 8, cutting piece 81, third bevel gear 82, fourth bracket 9, fourth bearing 91, fifth bracket 10, fifth bearing 101, second shaft Rod 11, fourth bevel gear 111, fifth bevel gear 112, third shaft rod 12, sixth bevel gear 121, spur gear 122, slide rail 13, slider 131, rack 14 and push plate 141, above base 1 The left side is fixedly connected with the first bracket 2, the right side above the base 1 is fixedly connected with the second bracket 3, the top of the first bracket 2 and the second bracket 3 are fixedly connected with the workbench 4, and the left side of the workbench 4 is provided with a first slot Hole 41, a first bearing 42 is embedded on th...

Embodiment 2

[0019] A push-type plank cutting device for construction, such as Figure 1-3As shown, it includes a base 1, a first support 2, a second support 3, a workbench 4, a first bearing 42, a third support 5, a second bearing 51, a third bearing 52, a first shaft 6, a first Bevel gear 61, second bevel gear 62, motor 7, mounting plate 8, cutting piece 81, third bevel gear 82, fourth bracket 9, fourth bearing 91, fifth bracket 10, fifth bearing 101, second shaft Rod 11, fourth bevel gear 111, fifth bevel gear 112, third shaft rod 12, sixth bevel gear 121, spur gear 122, slide rail 13, slider 131, rack 14 and push plate 141, above base 1 The left side is fixedly connected with the first bracket 2, the right side above the base 1 is fixedly connected with the second bracket 3, the top of the first bracket 2 and the second bracket 3 are fixedly connected with the workbench 4, and the left side of the workbench 4 is provided with a first slot Hole 41, a first bearing 42 is embedded on the...

Embodiment 3

[0022] A push-type plank cutting device for construction, such as Figure 1-3 As shown, it includes a base 1, a first support 2, a second support 3, a workbench 4, a first bearing 42, a third support 5, a second bearing 51, a third bearing 52, a first shaft 6, a first Bevel gear 61, second bevel gear 62, motor 7, mounting plate 8, cutting piece 81, third bevel gear 82, fourth bracket 9, fourth bearing 91, fifth bracket 10, fifth bearing 101, second shaft Rod 11, fourth bevel gear 111, fifth bevel gear 112, third shaft rod 12, sixth bevel gear 121, spur gear 122, slide rail 13, slider 131, rack 14 and push plate 141, above base 1 The left side is fixedly connected with the first bracket 2, the right side above the base 1 is fixedly connected with the second bracket 3, the top of the first bracket 2 and the second bracket 3 are fixedly connected with the workbench 4, and the left side of the workbench 4 is provided with a first slot Hole 41, a first bearing 42 is embedded on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com