Concrete maintenance device for highway project construction in winter

A technology of engineering construction and concrete, which is applied in the field of concrete pouring, can solve the problems of large cold shock stress, high surface temperature, hidden cold shock cracks, etc., and achieve the effects of reducing impact stress, ensuring integrity and preventing cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

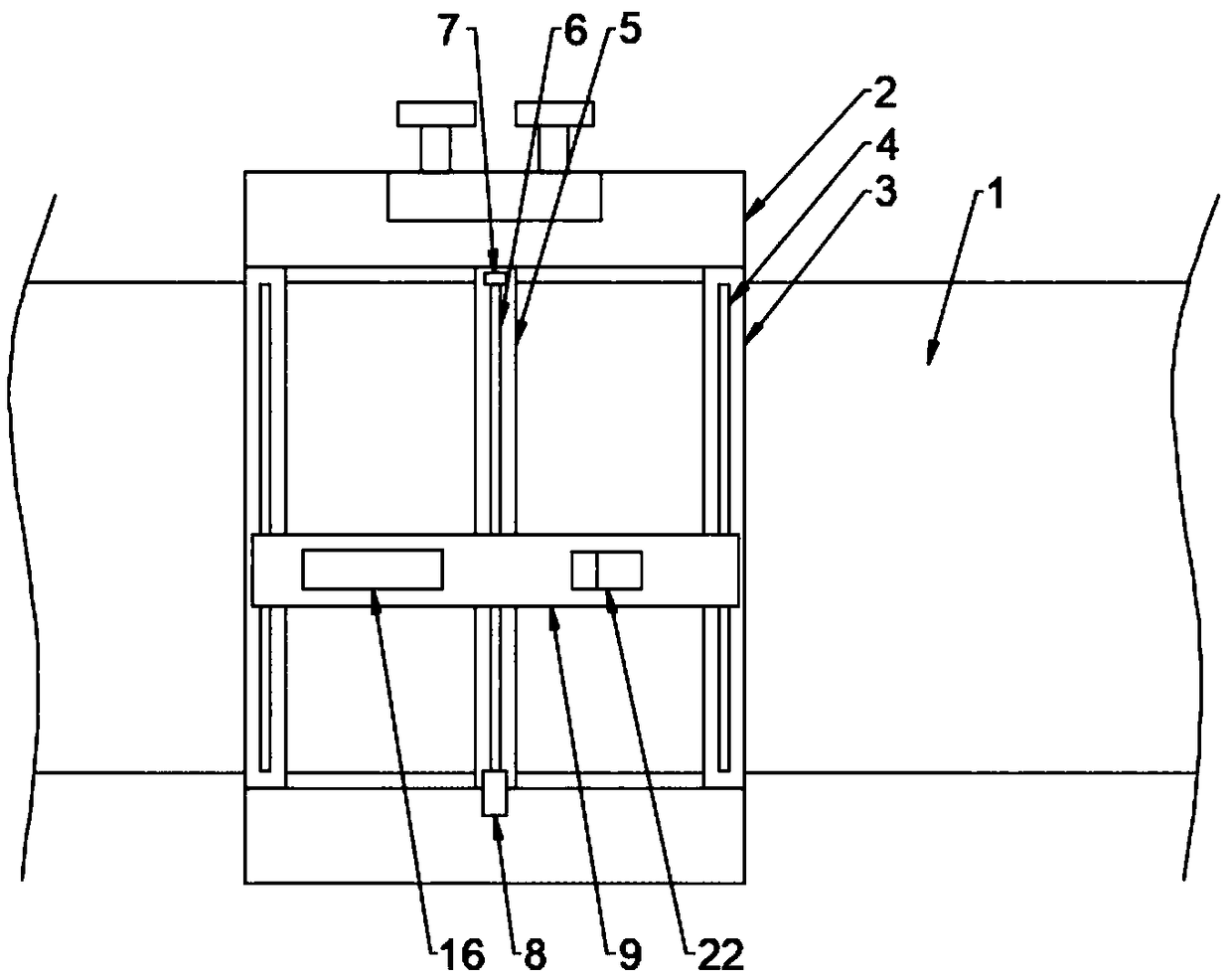

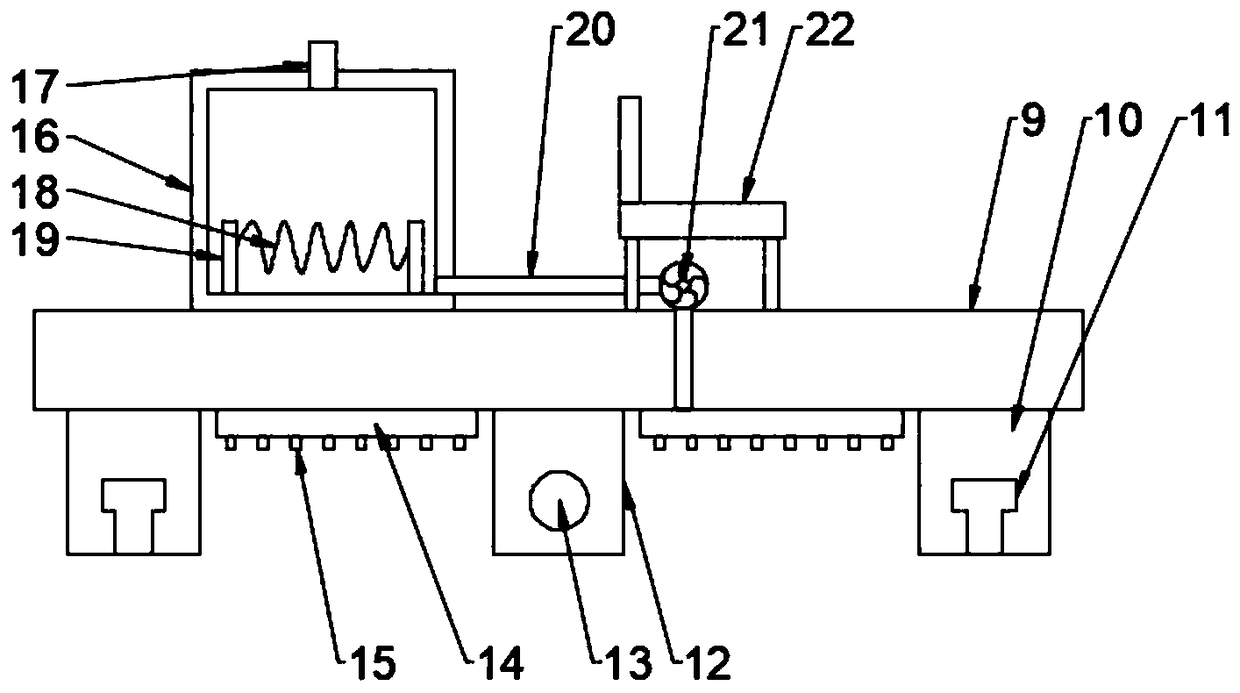

[0027] Embodiment 1, the whole device can walk slowly along the front and rear sides of the road body 1 through the walking wheels 201. Before spraying maintenance, add water to the water tank 16 and use the heating resistor 18 to heat the water to increase the water temperature. Then under the action of the water pump 21, the spray device 14 is drawn in, discharged through the nozzle 15, sprayed on the road body 1, the motor 8 is started, and the screw 6 is driven to rotate forward and reverse, and the water spray beam 9 is pushed along the The guide rail 4 moves back and forth, thereby evenly spraying on the entire front and back of the road body 1, so that the top surface of the entire road body 1 is maintained.

Embodiment 2

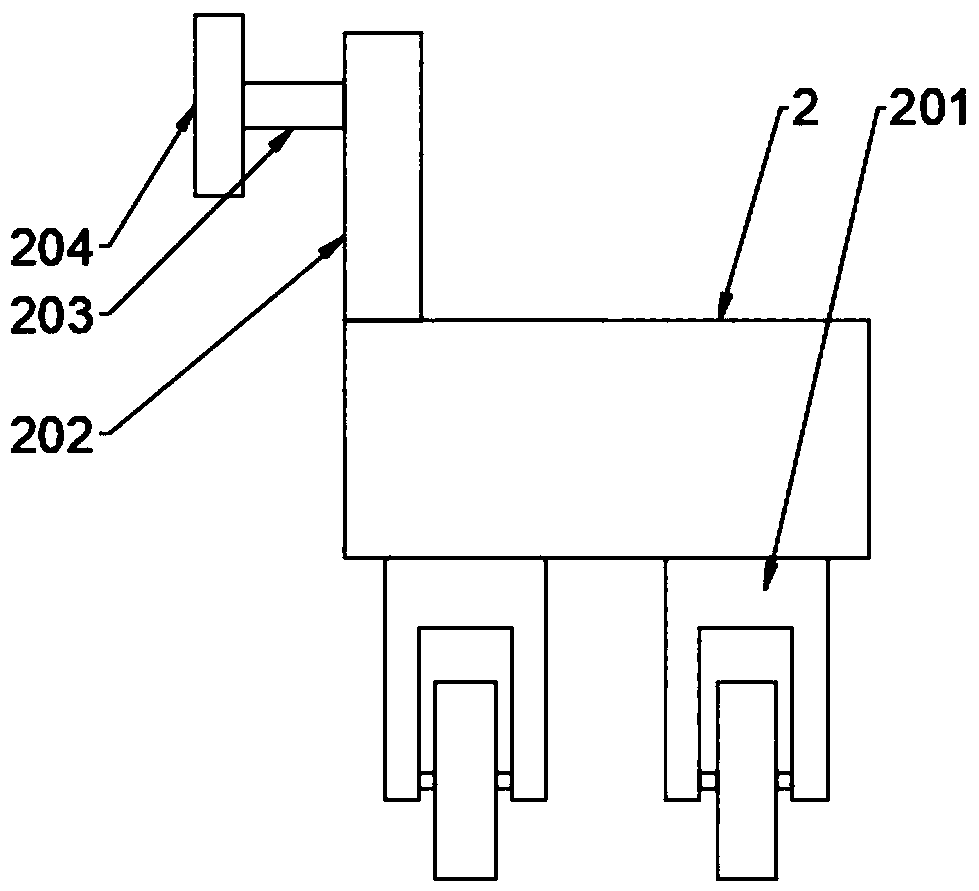

[0028] Embodiment 2, the difference between this embodiment and Embodiment 1 is: a support frame 202 is provided on the outside of the top surface of the support stand 2, and a number of fixed rods 203 are evenly provided on the top of the outer end of the support frame 202, All the fixed rods 203 are arranged side by side in parallel, and the other ends of the fixed rods 203 are fixedly connected to the connecting flange 204, and the connecting flange 204 is uniformly provided with several threaded holes, and is connected to the tractor through the connecting flange 204. The tractor drives the whole device to walk along the road body 1, which is convenient for watering and maintaining the road body 1 in all directions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com