Miniature spiral mortar stirring machine

A mixer and mortar technology, which is applied to cement mixing devices, clay preparation devices, unloading devices, etc., can solve the problems of low work efficiency, less mortar consumption, and is not suitable for large and medium-sized mixers, so as to reduce labor intensity and improve work efficiency. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

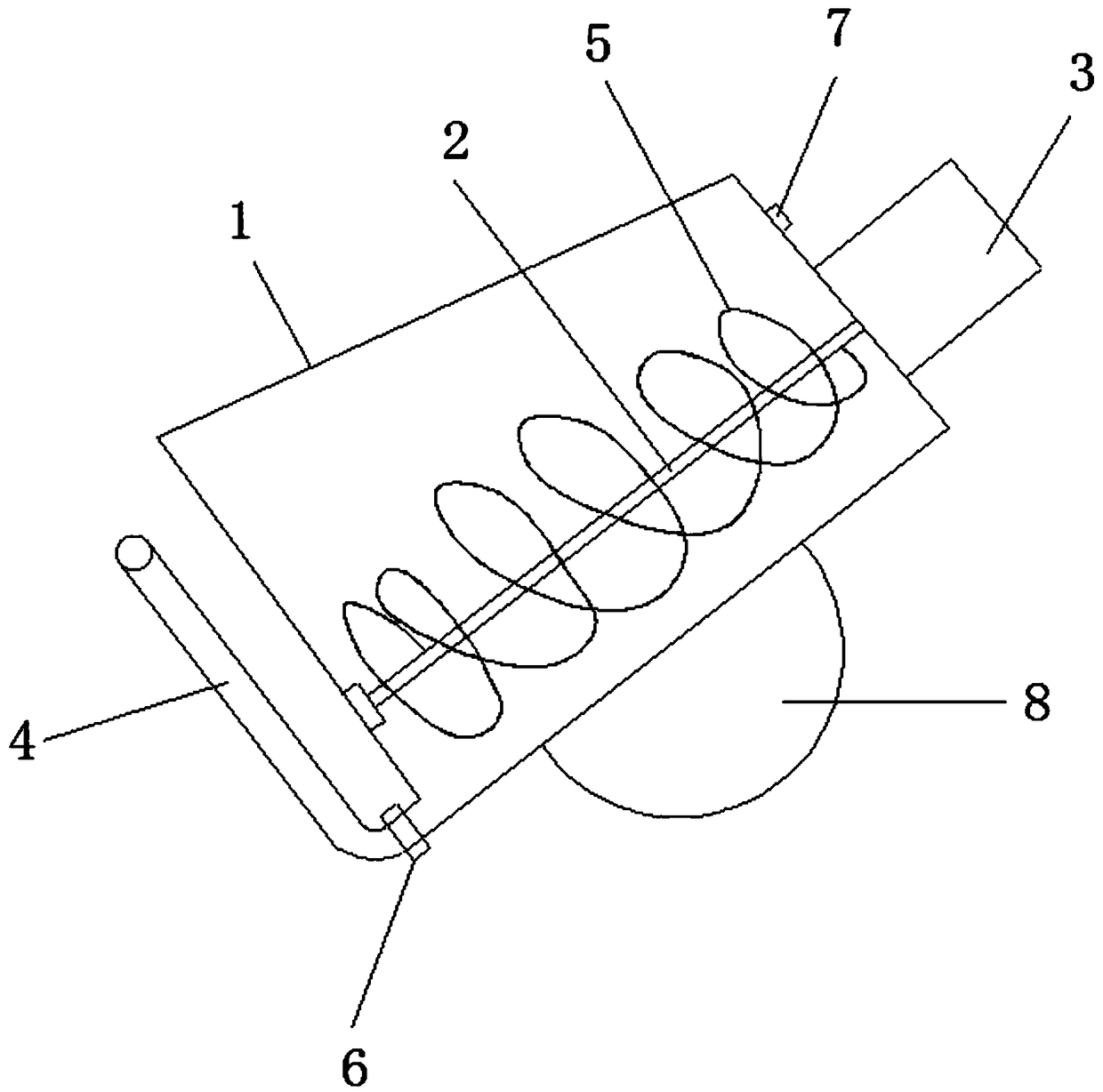

[0017] Such as figure 1 As shown, a miniature spiral mortar mixer includes a hopper 1, a rotating shaft 2, a reduction motor 3 and a discharge pipe 4. Mortar is housed in the hopper 1, and the reduction motor 3 that can be rotated forward and reverse is fixed on the outer side of one end thereof. The hopper 1 is provided with a button 7 for controlling the geared motor 3 to rotate forward to stir the mortar or reversely to discharge the stirred mortar from the discharge pipe 4 after triggering. One end of the rotating shaft 2 is rotatably mounted on the inner wall of one end of the hopper 1, and the other end extends horizontally along the axial direction of the hopper 1 toward the direction of the geared motor 3 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com