A device for integrally forming a stereoscopic vamp pattern

A technology of forming shoe uppers and three-dimensional, applied in the direction of household components, household appliances, other household appliances, etc., can solve the problems of material hardening, easy to change material structure, easy to destroy material structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to understand the technical characteristics and practical effects of the present invention in detail, and to realize them according to the contents of the description, the preferred embodiment shown in the figure is further described in detail as follows:

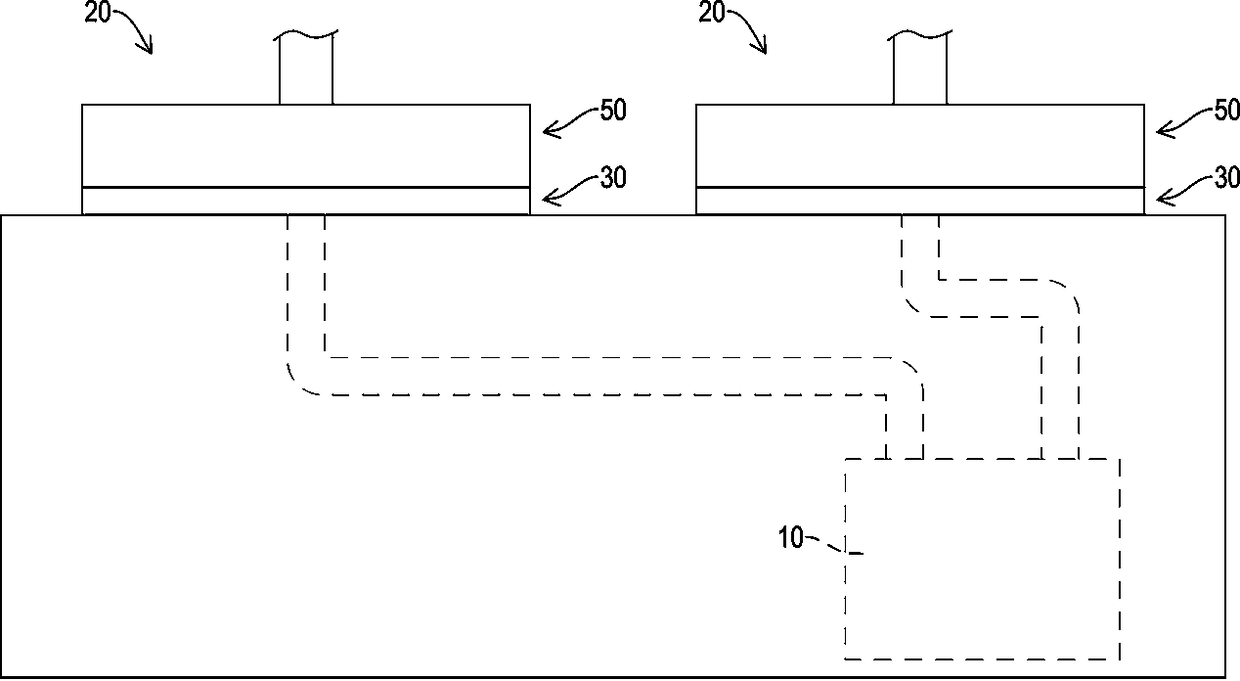

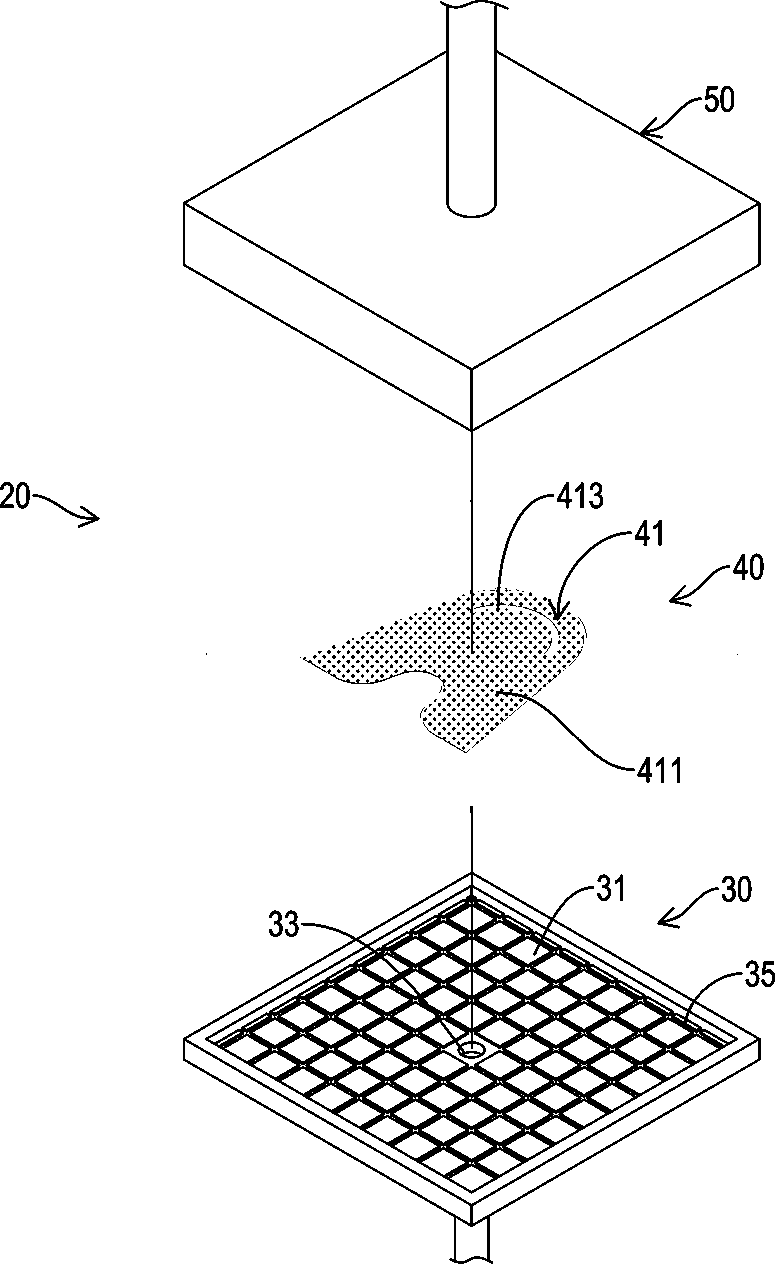

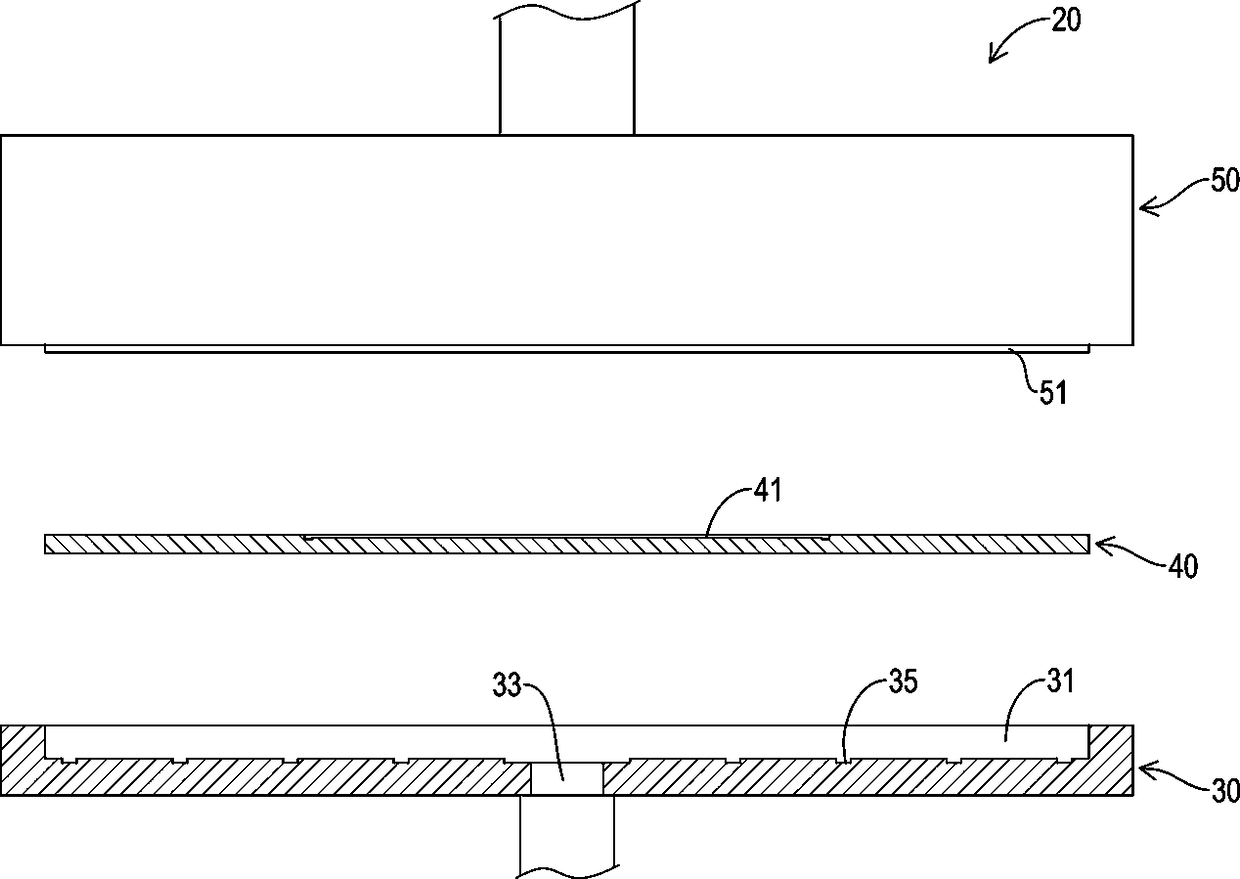

[0021] see figure 1 , is a preferred embodiment of the present invention, which includes a vacuum device 10 and two forming dies 20; the vacuum device 10 is used to generate negative pressure suction, and is connected with the two forming dies 20 by pipelines, please refer to figure 2 and image 3 , each forming die 20 comprises a mold base 30, a ceramic template 40 and a hot press seat 50, wherein:

[0022] The mold base 30 includes an accommodating groove 31 and an air extraction channel 33, the accommodating groove 31 is recessed on the top surface of the mold base 30, and a plurality of criss-cross arrangements are recessed on the bottom surface of the accommodating groove 31 The air pumping channel 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com