CCM double sided sealed layer laminating method

A technology of sealing layer and sealing bottom layer, which is applied in the direction of chemical instruments and methods, lamination, lamination devices, etc., can solve the problems of high lamination deviation of sealing layer, reduce product optimization and protection, and achieve the goal of preventing excessive deviation Effect

Inactive Publication Date: 2018-11-16

贵州贵安新区众鑫捷创科技有限公司

View PDF3 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The current CCM double-sided sealing layer bonding method has the following shortcomings. It cannot calibrate the accuracy of the double-sided sealing layer to the greatest extent. After the double-sided sealing layer is bonded, it may increase the problem of excessive deviation of the sealing layer. , and it is not possible to perform trimming cutting, chamfering and vacuum packaging after the CCM double-sided sealing layer is pasted, which reduces the maximum product optimization and protection of the CCM after the CCM double-sided sealing layer is pasted.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

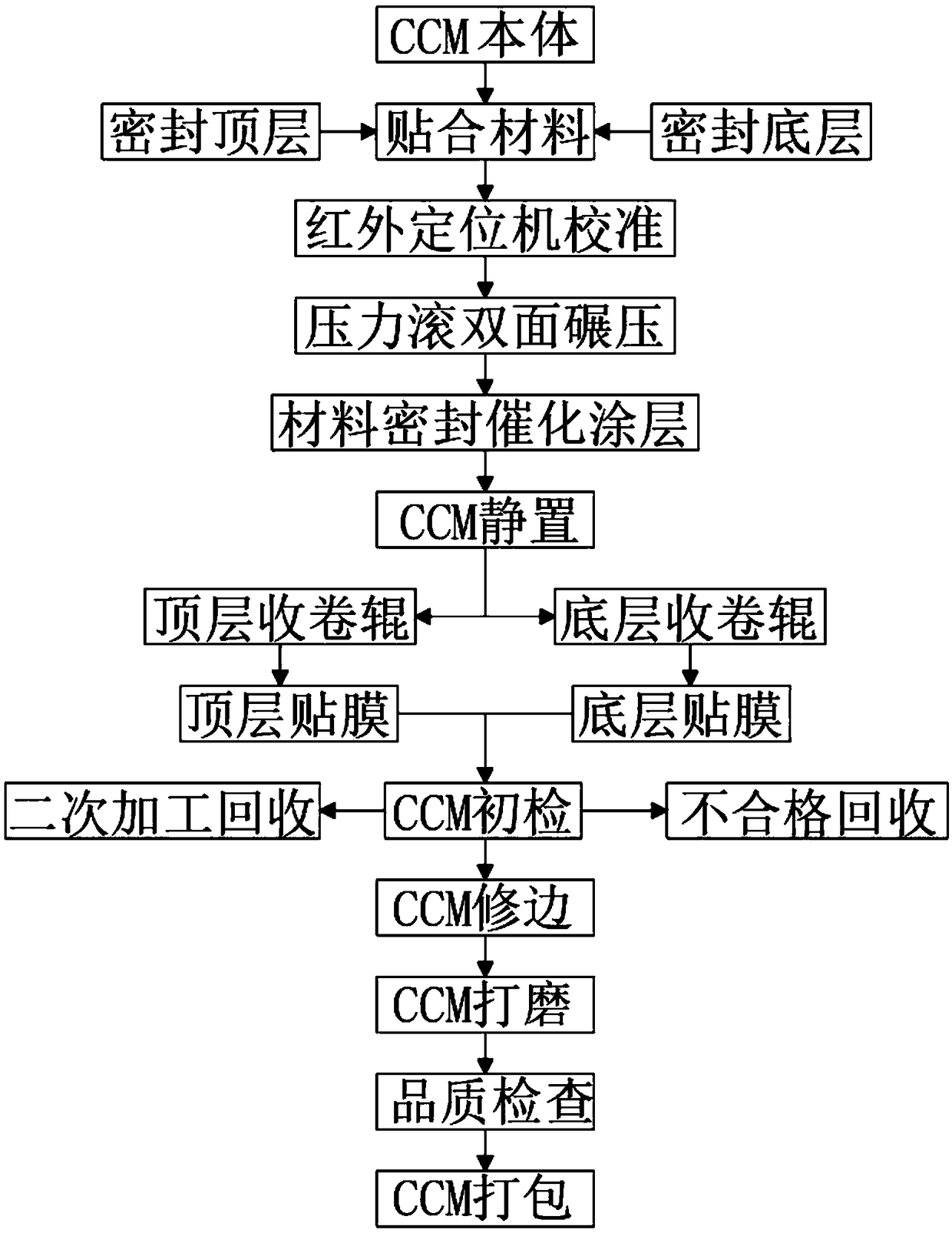

[0035] Such as Figure 1-3 The shown CCM double-sided sealing layer bonding method includes the following steps:

[0036] S1, CCM body: select the CCM body and fix it on the laminating machine;

[0037] S2. Sealing top layer, bonding material and sealing bottom layer: Place the sealing top layer and sealing bottom layer mixed with bonding materials on both sides of the CCM body;

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a CCM double sided sealed layer laminating method, which comprises following steps: CCM body preparation, top layer sealing, material lamination, bottom layer sealing, infraredpositioning machine calibration, pressure roller double sided rolling, catalytic coating sealing, CCM standing, top layer roller winding, top layer film pasting, bottom layer roller winding, bottom layer film pasting, CCM primary examination, second processing and recovering, disqualified product recovering, CCM trimming, CCM polishing, quality detection, and CCM packaging. The method has the advantages that in the CCM double sided sealed layer laminating method, steps of infrared positioning machine calibration, CCM trimming, CCM polishing, and CCM packaging are added; the step of infrared positioning machine calibration can maximally improve the precision of double sided sealed layer lamination and calibration, the problem of large deviation in double sided sealed layer lamination is solved; CCM trimming and CCM polishing can maximally optimize the CCM after double sided sealed layer lamination; in the CCM packaging step, CCM is packed in vacuum, and thus the CCM is maximally protected during the long process of transportation and storage.

Description

technical field [0001] The invention relates to the field of catalyst-coated membranes (CCM for short), in particular to a bonding method for double-sided sealing layers of CCMs. Background technique [0002] The CCM double-sided sealing layer bonding method is to attach a sealing layer to the catalytic coating on both sides of the CCM before the actual use of the CCM to protect the CCM for a long time, so that the CCM catalytic coating is well protected. It can guarantee the performance of CCM to the greatest extent when using it. [0003] The current CCM double-sided sealing layer bonding method has the following shortcomings. It cannot calibrate the accuracy of the double-sided sealing layer to the greatest extent. After the double-sided sealing layer is bonded, it may increase the problem of excessive deviation of the sealing layer. , and it is not possible to perform trimming cutting, chamfering and vacuum packaging after the CCM double-sided sealing layer is attached,...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B32B37/10B32B38/10B32B38/18B32B43/00B32B38/00

CPCB32B37/0053B32B37/10B32B38/00B32B38/0012B32B38/10B32B38/1841B32B43/003B32B2038/0016

Inventor 余锦旺

Owner 贵州贵安新区众鑫捷创科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com