Can cap and spray can

A technology of can lid and lid, applied in the field of spray device, can solve the problems of inconvenient operation, pollution, waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

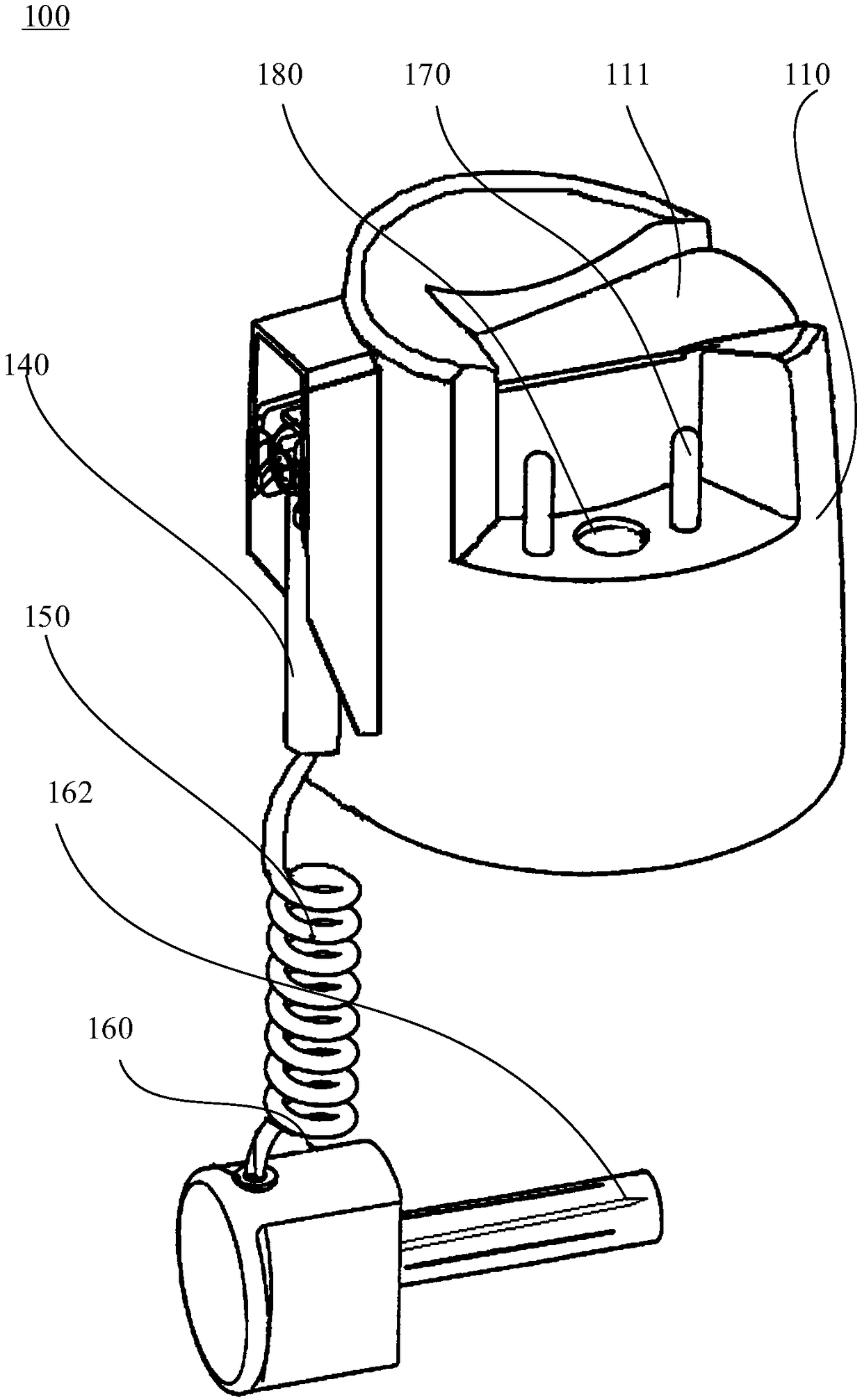

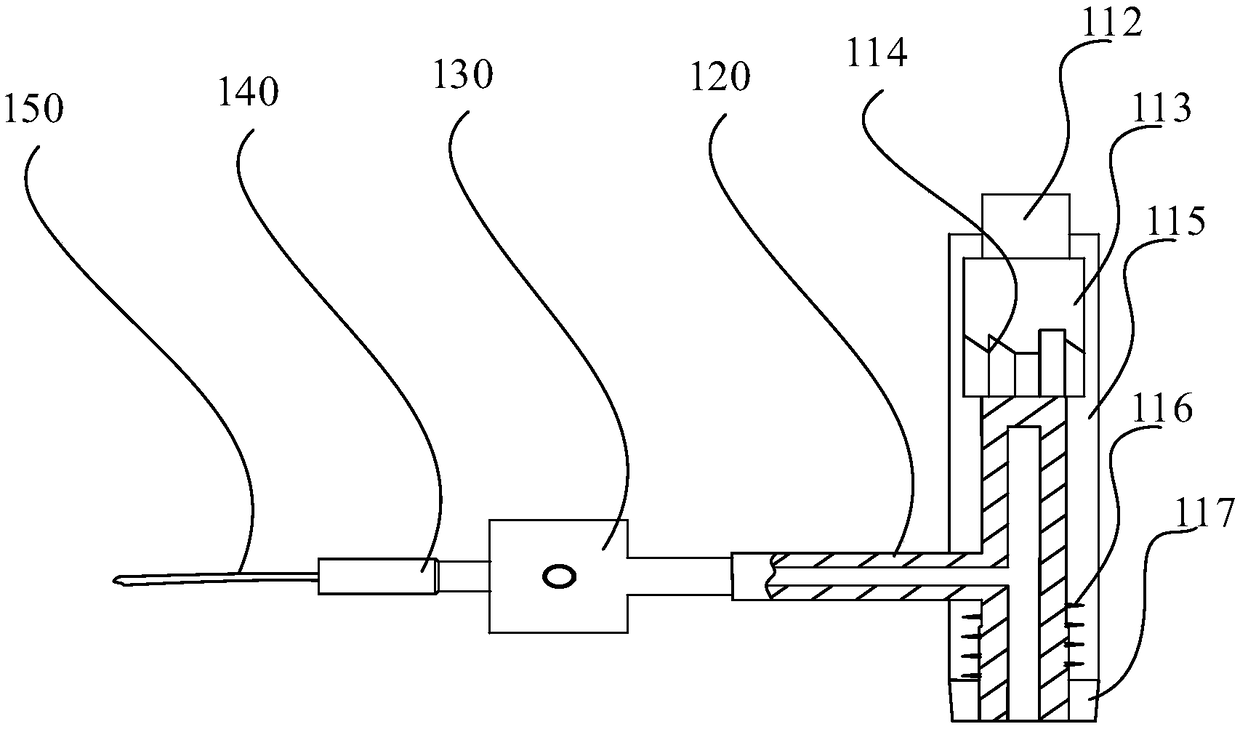

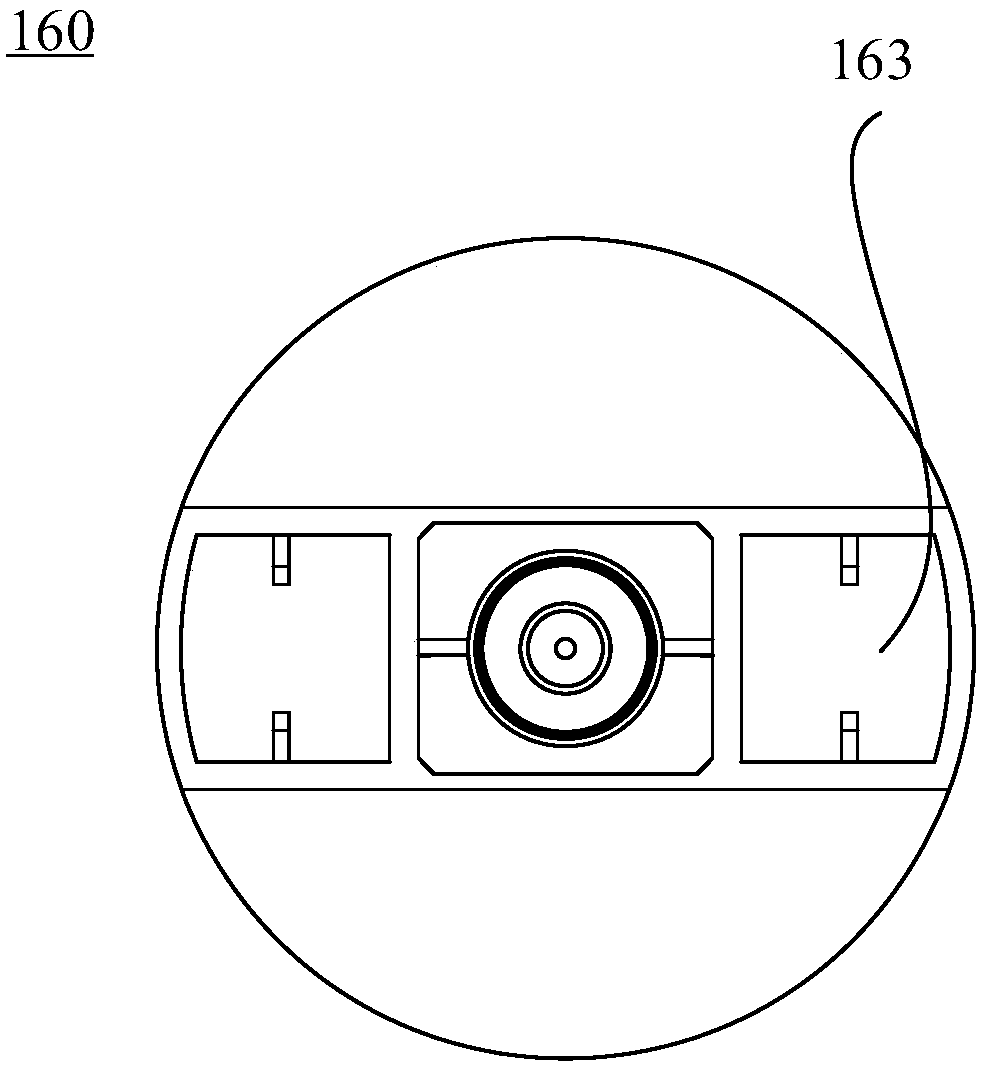

[0031] Please refer to figure 1 , the embodiment of the present invention provides a tank cover 100, including a gland 110, a pressing part 111 is arranged on the gland 110, a push rod 112 is connected under the pressing part 111, and a part of the push rod 112 is arranged in a sleeve 115, and the push rod The end of 112 is provided with a rotating tooth, a chute 113 is arranged below the rotating tooth, a turntable 114 is arranged below the chute 113, and a plurality of convex ribs are evenly distributed on the side wall of the turntable 114, and the number of the chute 113 and the convex ribs are the same and are arranged in cooperation with each other. The rotating gear abuts against the rotating disk 114, and a T-shaped connecting rod 120 is arranged below the rotating disk 114. A wing end of the T-shaped connecting rod 120 is provided with a spring 116, and the sleeve 115 is provided with a limit sleeve 117 at the end of the spring 116. To limit the position of the spring...

Embodiment 2

[0056] The embodiment of the present invention also provides a spray can, comprising a tank body, a nozzle pipe and any one of the above-mentioned tank caps 100, the tank cap 100 is arranged on the tank body, and the T-shaped connecting rod 120 of the tank cap 100 communicates with the nozzle pipe.

[0057] The tank body is a pressure-resistant tank, and there is a preparation in the tank, which is used for spraying to repel or kill insects. The composition and dosage of the preparation are set according to actual needs. Spray cans have different repelling and insecticidal principles depending on the preparation in the tank. For example, when the spray can is used as an aerosol spray can, there are stock solution and propellant in the tank, and the stock solution and propellant are packaged together in the can In vivo, when used, the formulation sprayed in mist form can have an anthelmintic or insecticidal effect.

[0058] In the spray tank provided by the embodiment of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com