Circular hoist for construction

A hoisting machine and construction technology, applied in hoisting devices, portable lifting devices, etc., can solve the problems of wasting physical strength, high operators, and personnel falling, and achieve saving installation operations, low cost and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

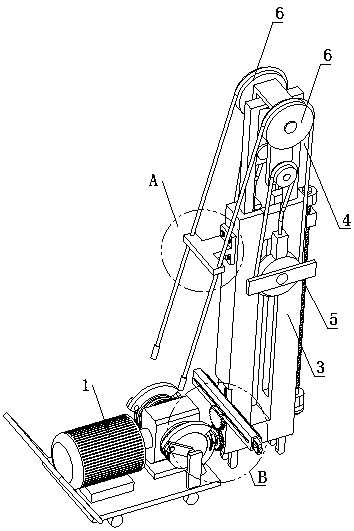

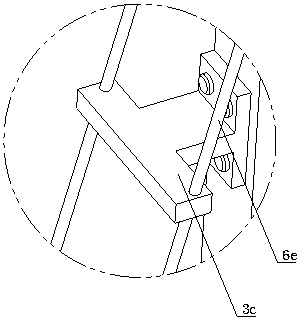

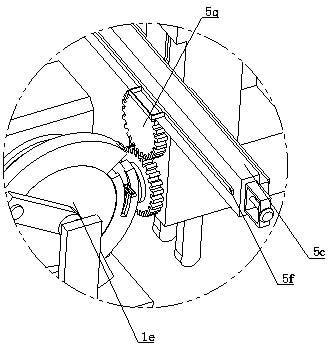

[0024] refer to Figure 1 to Figure 9 The circular hoist for construction shown includes a two-way drive device 1, a load-bearing body 3, a load-bearing auxiliary body 4, a manual lifting device 5, and two pulley blocks 6, and the load-bearing auxiliary body 4 can move vertically through the manual lifting device 5. The two pulley blocks 6 are respectively installed on the front and rear sides of the bearing sub-body 4 , and both are located at the top of the bearing sub-body 4 . The two-way driving device 1 includes a servo motor 1c and two symmetrically arranged quick-release discs 1e. The servo motor 1c is respectively connected to a detachable pulley block 6 through the two quick-release discs 1e. The servo motor 1c is used to drive the two quick-release discs 1e. The disks 1e can rotate around their own axes r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com