Production process of DTY silk yarn

A production process and silk thread technology, which is applied in the field of DTY silk thread production process, can solve problems such as broken wires, and achieve the effects of improving quality, reducing breakage, and reducing broken wires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

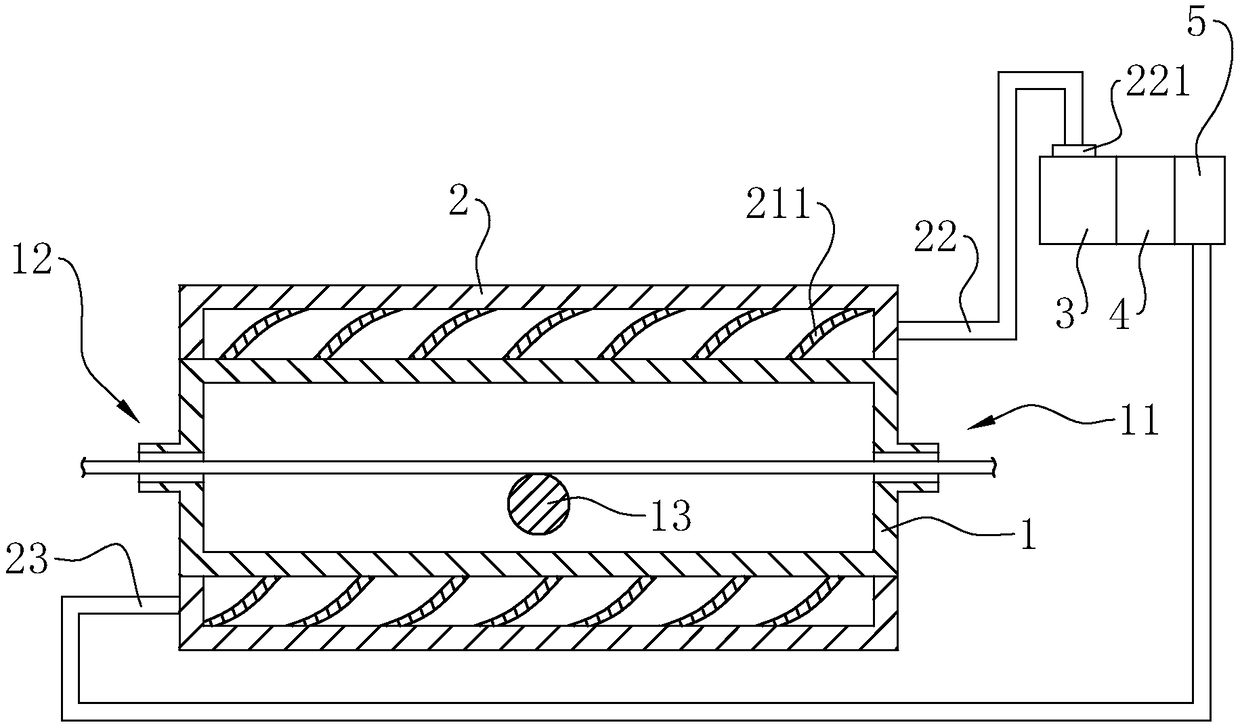

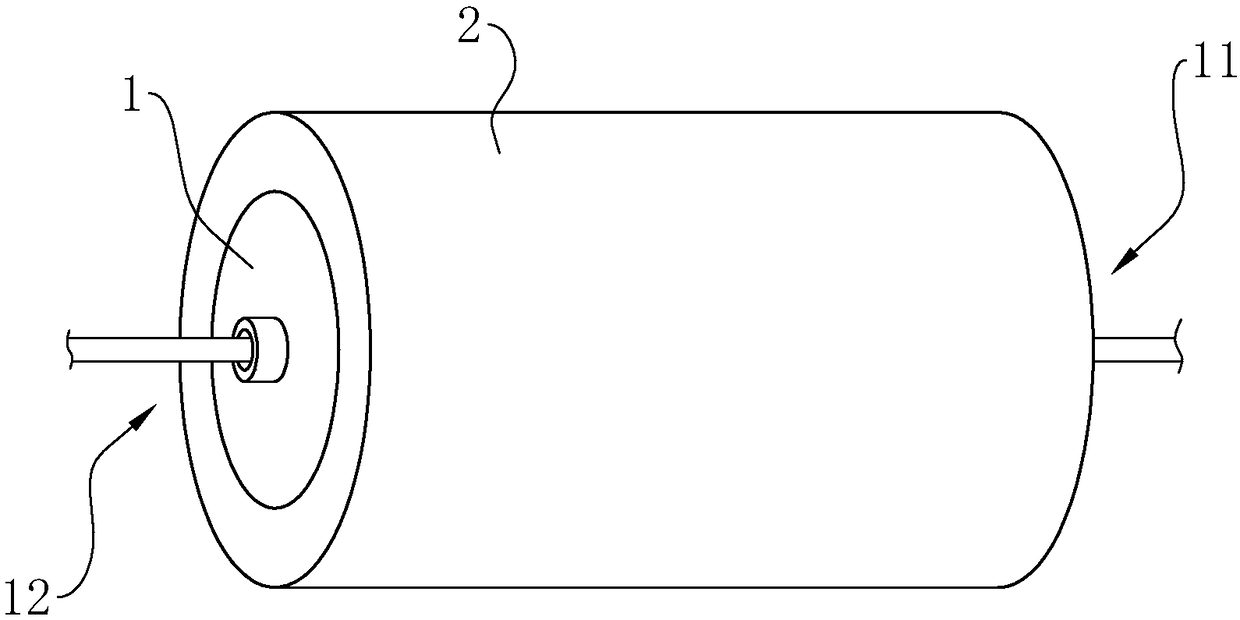

Image

Examples

Embodiment

[0042] Embodiment: a kind of production technology of DTY silk thread, comprises the steps:

[0043] S1, carry out a roller pull on the island POY yarn, and feed it into the first hot box for heating;

[0044] S2, cooling the heated sea-island POY yarn, false twisting the cooled sea-island POY yarn to form a raw yarn;

[0045] S3, carry out two roller pulls on the raw yarn after false twisting, and feed it into the second hot box for heating to form semi-finished yarn, and cool it through the cooling plate;

[0046] S4, feeding the high-shrinkage FDY yarn through the zero roller, so that the high-shrinkage FDY yarn is wound on the outside of the semi-finished yarn to form a preliminary composite yarn;

[0047] S4, spraying air on the preliminary composite yarn, so that network points arranged at intervals are formed on the surface of the preliminary composite yarn, and the DTY composite yarn is output;

[0048] In S5, the DTY composite yarn is pulled by three rollers, and th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap