A self-adaptive waste cutting method for a cutting bed

A self-adaptive, scrap technology, applied in the field of cutting bed, to ensure the quality of cutting, improve the efficiency of manual material collection, and liberate the labor force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

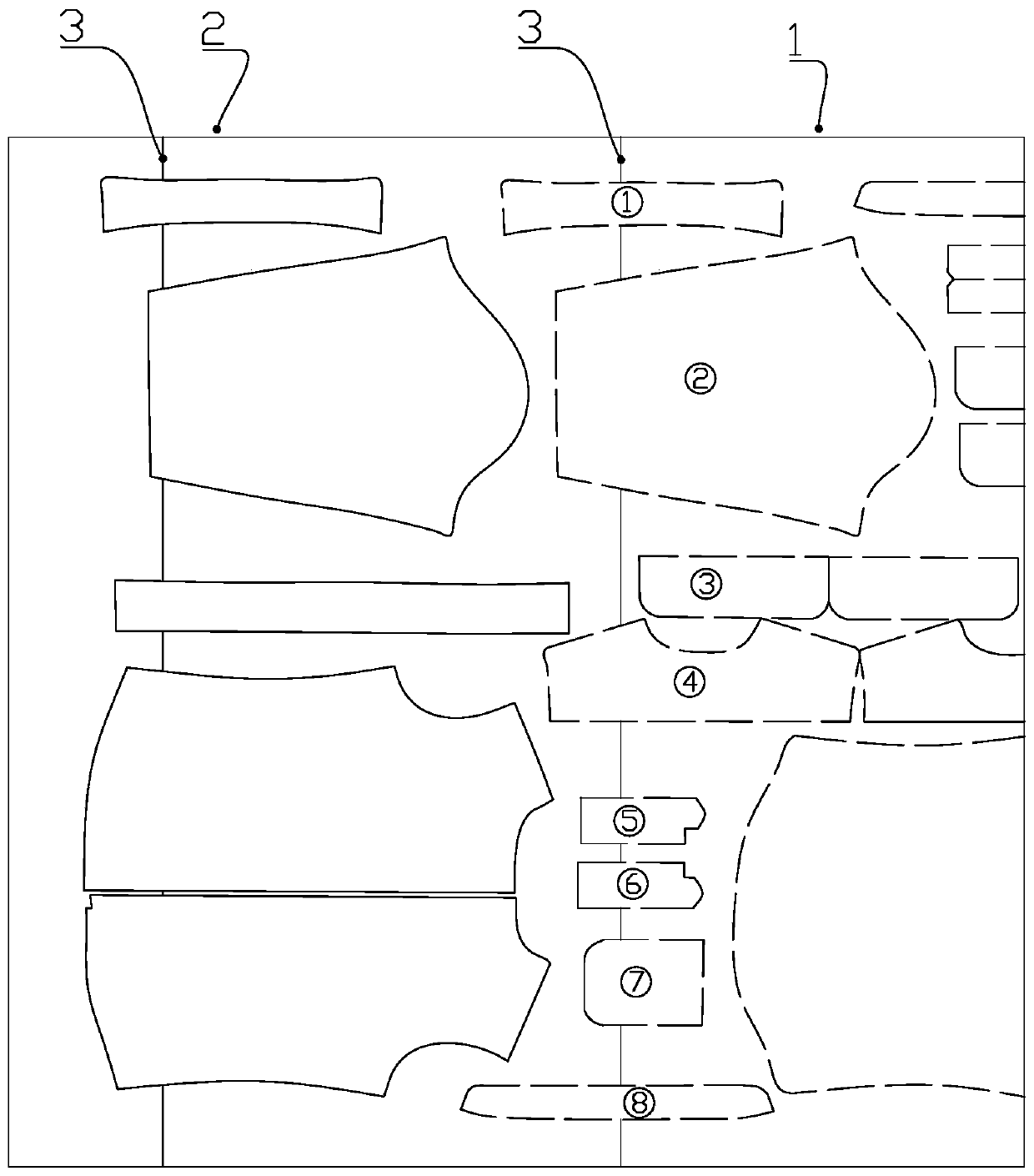

[0019] The present invention will be further described below with specific embodiment, see figure 1 :

[0020] A cutting bed adaptive waste cutting method, comprising the following steps:

[0021] (1) Load the CAD drawing, analyze and generate the cutting diagram; the CAD drawing is the whole cutting diagram.

[0022] (2) Obtain the cutting piece data of the current window 1 and the next window 2 in the cutting diagram, and calculate the reasonable vertical waste cutting position of the current window 1; figure 1 As shown, the dotted line in the figure shows the current window 1, and the solid line shows the next window 2.

[0023] Because of the different sizes and positions of the pieces, there are always some pieces located between the two windows, that is to say, they belong to both the current window 1 and the next window 2. We call this type of piece A and define it Cut piece A is the next window cut piece. The current window 1 needs to ensure that the cutting area o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com