Bending-shear stress separated fabricated shear wall and construction method thereof

A shear wall and prefabricated technology, applied to walls, building components, buildings, etc., can solve the problems of difficult quality control, low construction efficiency, time-consuming and labor-intensive problems, and achieve simple and easy connection, simplified construction steps, and stress clear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

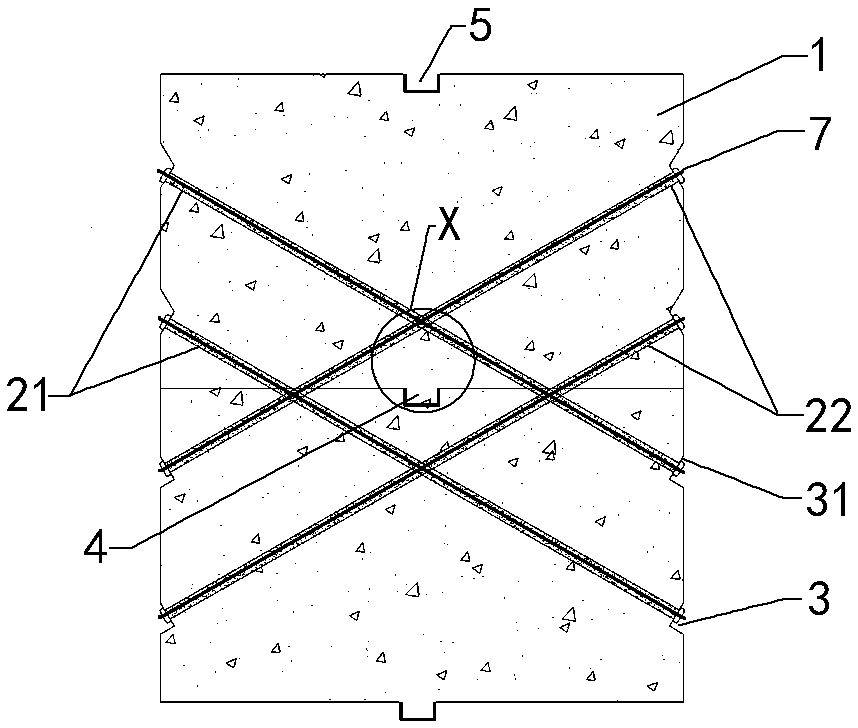

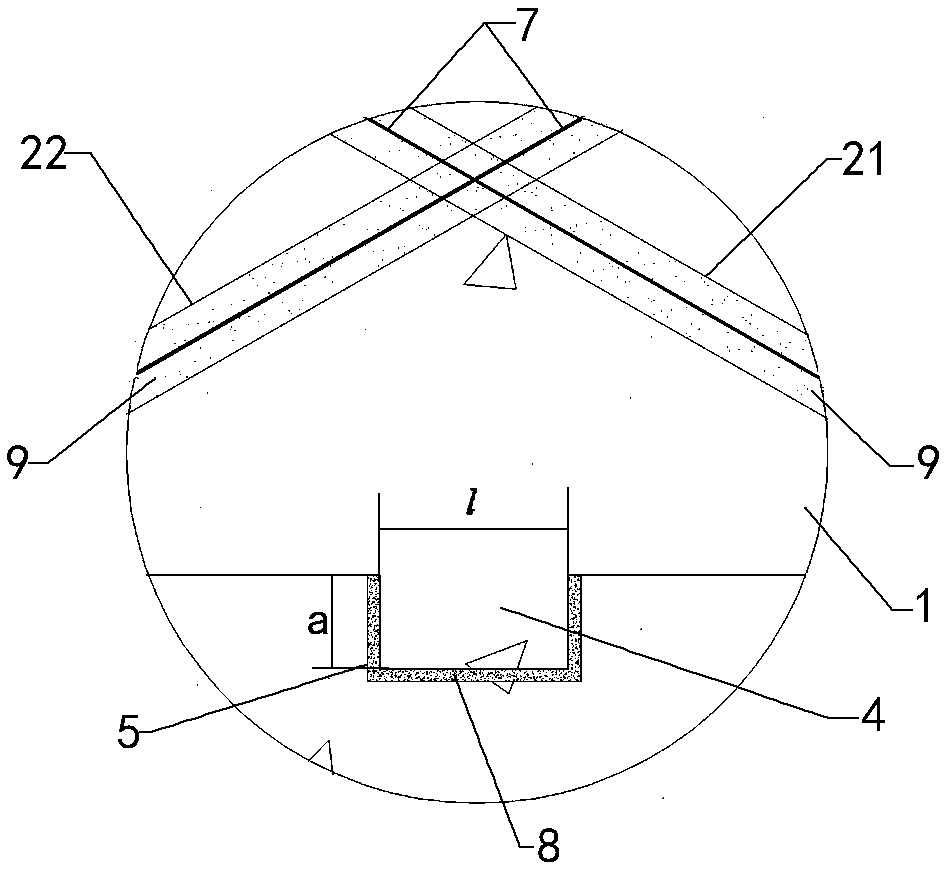

[0035] Such as figure 1 As shown in the present invention, the prefabricated shear wall with separated bending and shearing forces, the shear wall in a single floor is composed of unit wall panels 1 spliced up and down, and adjacent unit wall panels 1 are connected by 7 prestressed tendons.

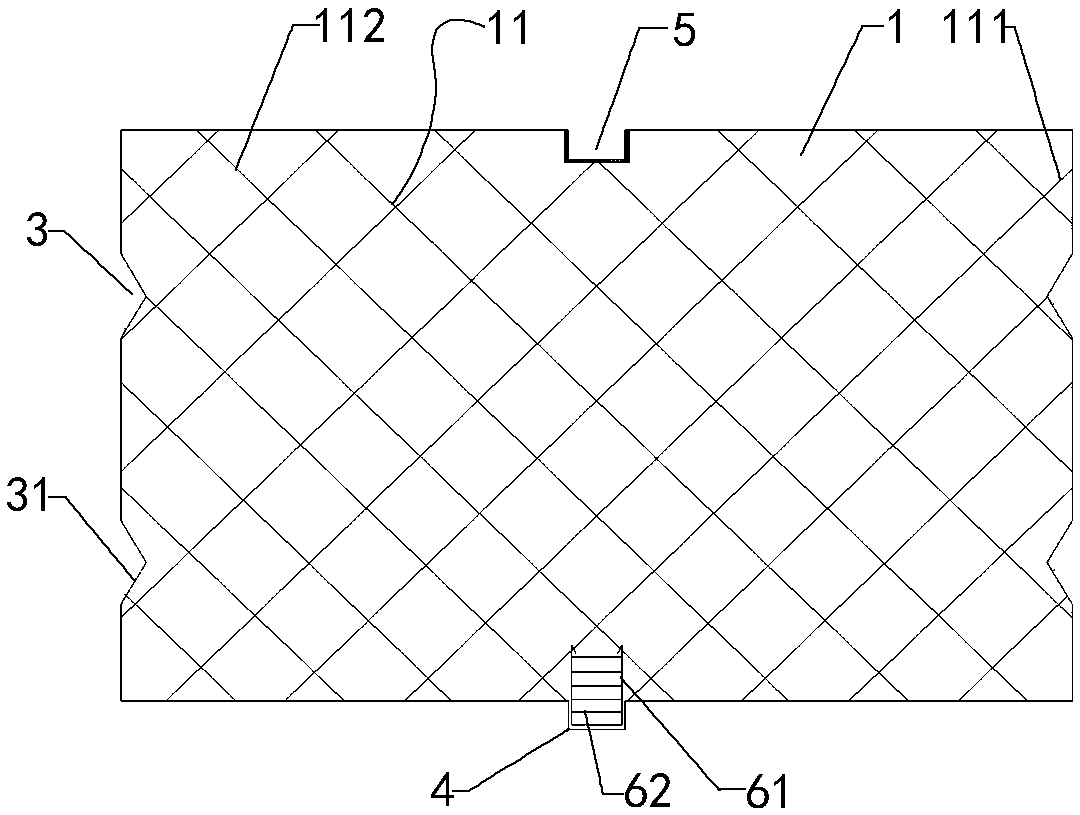

[0036] Such as figure 2 As shown, the unit wall panel 1 is a reinforced concrete structure, and the internal steel skeleton 11 includes left oblique bars 111 and right oblique bars 112 perpendicular to each other, and the angle between the left oblique bars 111 and the horizontal direction is 45°.

[0037] Such as image 3 As shown, the top of the unit wall panel 1 is provided with a downwardly recessed shear groove 5, and the bottom end is provided with a shear key 4 corresponding to the shear groove 5 and protruding upward, and the shear key 4 at the bottom of the unit wall panel 1 The key 4 is mated with the shear groove 5 on the top of the adjacent unit wall panel 1 , and the joi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com