Dismantling system of glass curtain wall and using method thereof

A glass curtain wall and suction cup technology, which is applied in the direction of walls, building maintenance, and building components, can solve the problems of large amount of glass curtain wall waste, hidden dangers of glass slag, and inability to recycle, so as to reduce the difficulty of safety prevention and control, solve The effect of making it impossible to reuse and improving the efficiency of demolition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

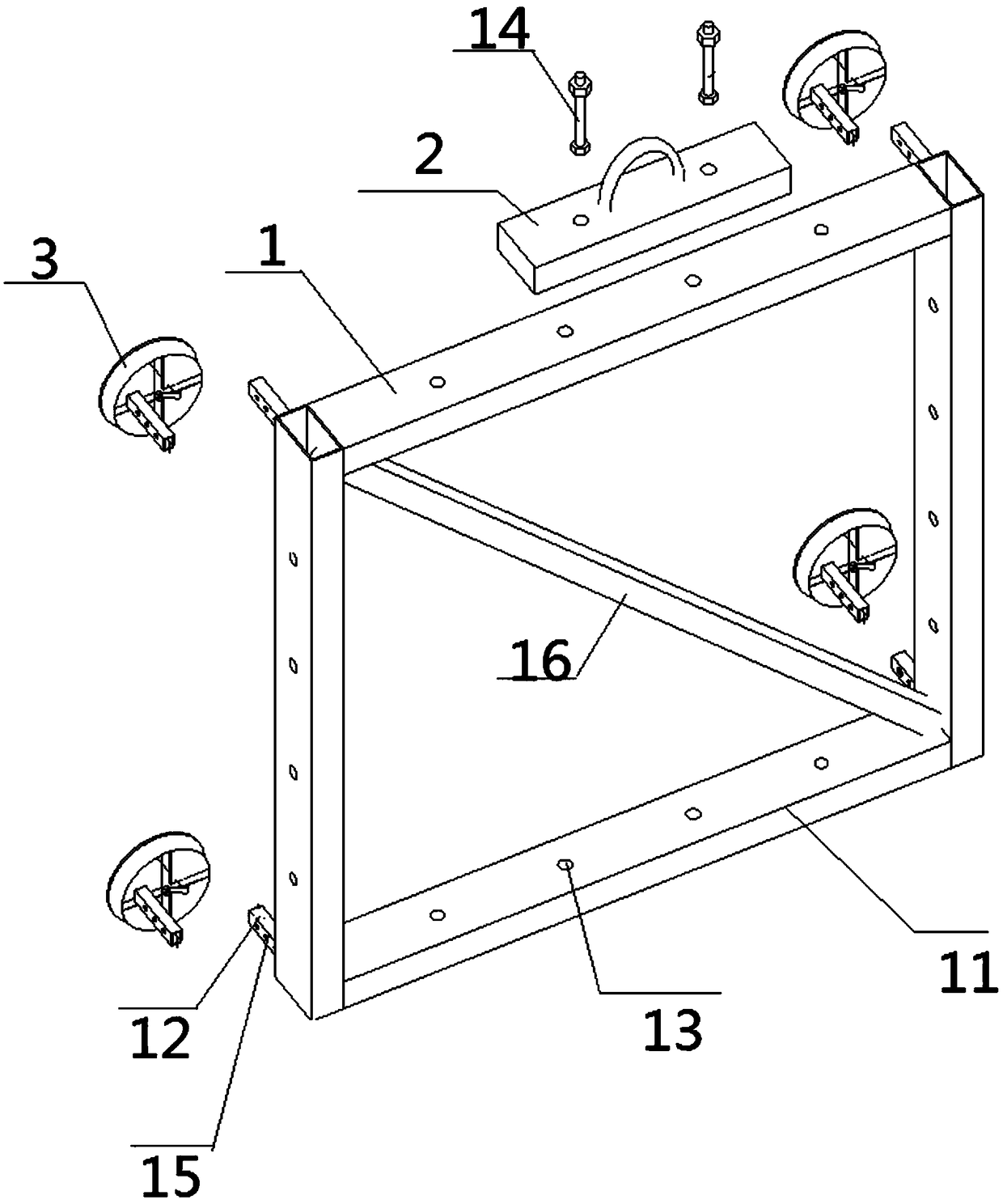

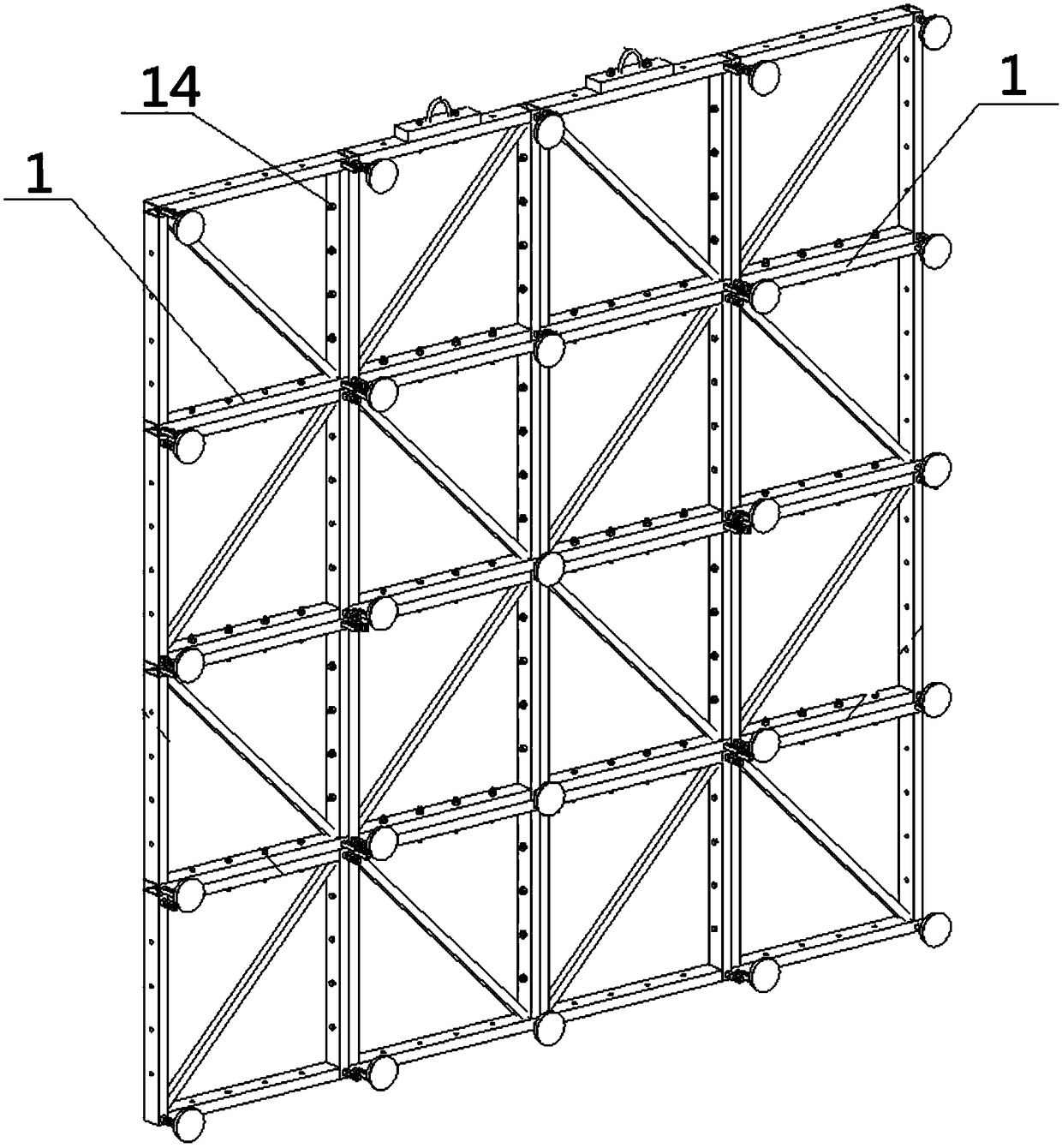

[0036] refer to figure 1 , the present embodiment provides a technical solution of a glass curtain wall dismantling system as follows:

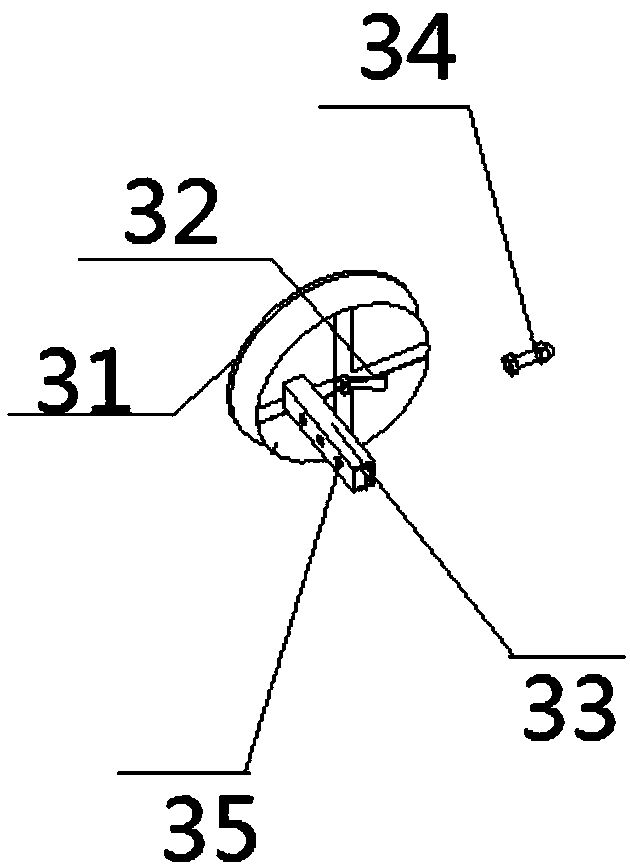

[0037] A glass curtain wall dismantling system, used for the dismantling of hidden glass curtain walls, including a truss module 1, a hoisting element 2 and a suction cup device 3, the truss module 1 includes a frame body 11, and is vertically arranged on the frame body 11 The connecting rod 12, the frame body 11 is provided with several bolt holes 13 at intervals, the suction cup device 3 is arranged at the end of the connecting rod 12, the hoisting original part 2 is arranged on the top of the glass curtain wall dismantling system and The truss module 1 is connected to the truss module 1 through the connecting bolt assembly 14 passing through the bolt hole 13 .

[0038] When the glass curtain wall dismantling system of this embodiment is used, the glass curtain wall dismantling system is hoisted to the area to be dismantled glass curtain w...

Embodiment 2

[0049] This embodiment provides a method for using the glass curtain wall dismantling system of Embodiment 1, and the technical scheme is as follows:

[0050] refer to Figure 4 to Figure 6 , a method for using a glass curtain wall dismantling system, comprising the steps of:

[0051] In the first step, according to the size and layout characteristics of the glass curtain wall 4 to be demolished, the truss module 1 is selected to form a glass curtain wall demolition system;

[0052] In the second step, the glass curtain wall dismantling system is hoisted to area 4 where the glass curtain wall is to be dismantled by vertical transportation equipment such as tower cranes and roof cranes;

[0053] In the third step, the suction cup device 3 of the dismantling system of the glass curtain wall is adsorbed on the glass curtain wall 4 to be dismantled;

[0054] The fourth step is to cut the aluminum alloy frame 5 after the glass curtain wall 4 to be removed along the boundary of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com