Automatic releasing device of accumulated water for vacuum pump oil tank

An automatic release and vacuum pump technology, applied in the direction of valve operation/release device, valve device, pumping device for elastic fluid, etc., can solve the problem of damage to the lubrication performance of the pump head, failure of the vacuum pump, pump body and Rotor rust and other problems, to avoid adverse effects, prolong service life, ensure the effect of lubricating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The applicant will describe in detail below in the form of the embodiment, but the description of the embodiment is not a limitation to the solution of the present invention, and any equivalent transformation made according to the concept of the present invention is only in form and not in substance. It should be regarded as the scope of the technical solution of the present invention.

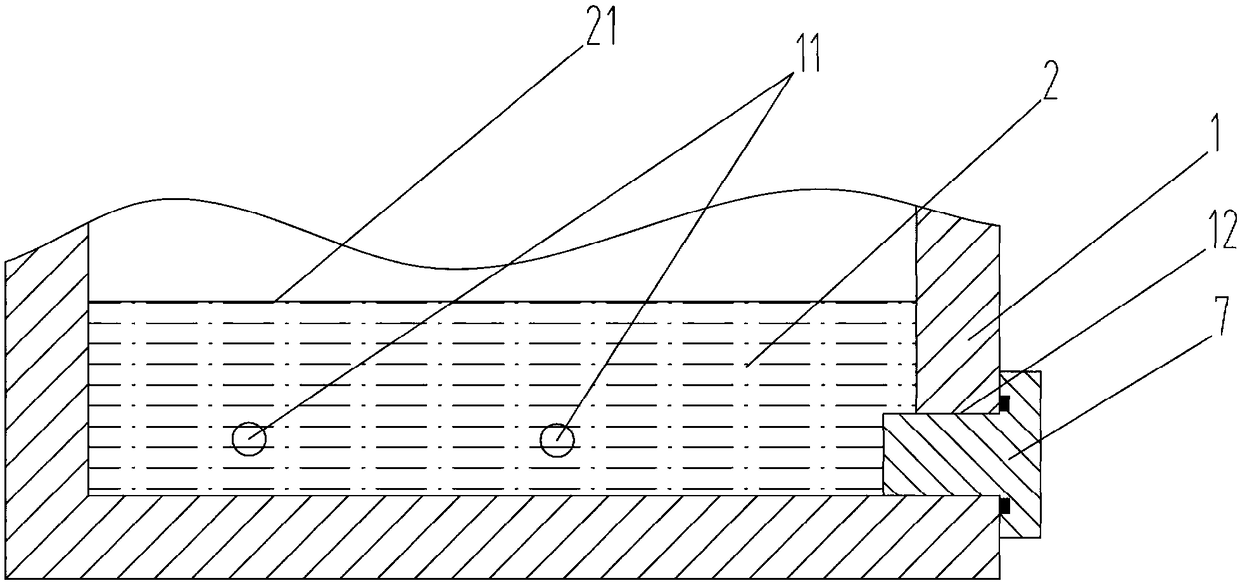

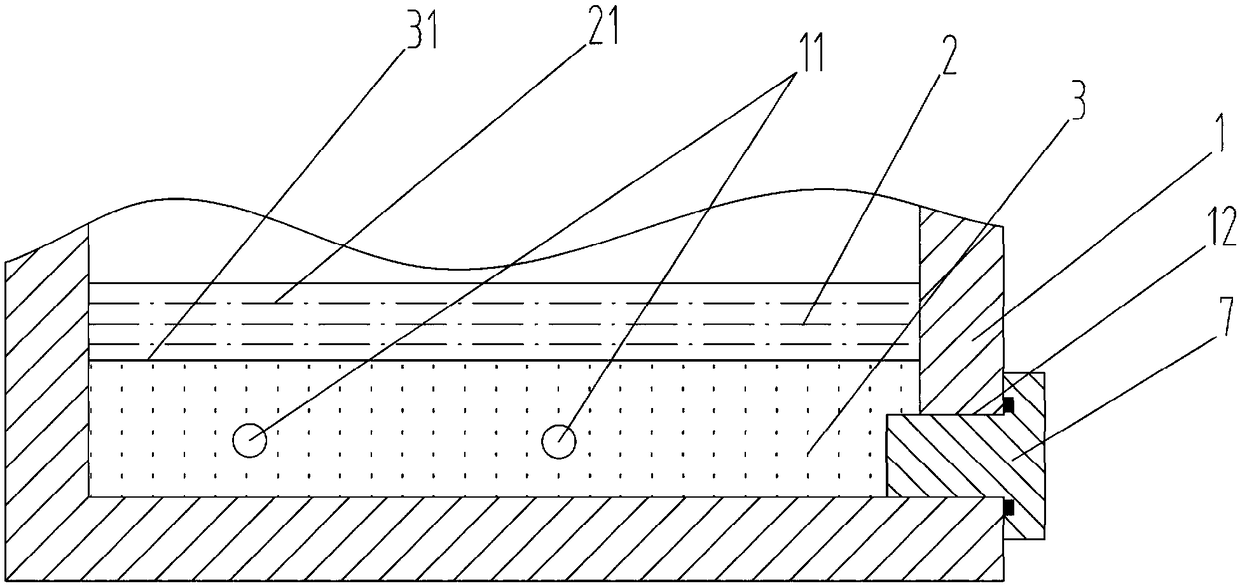

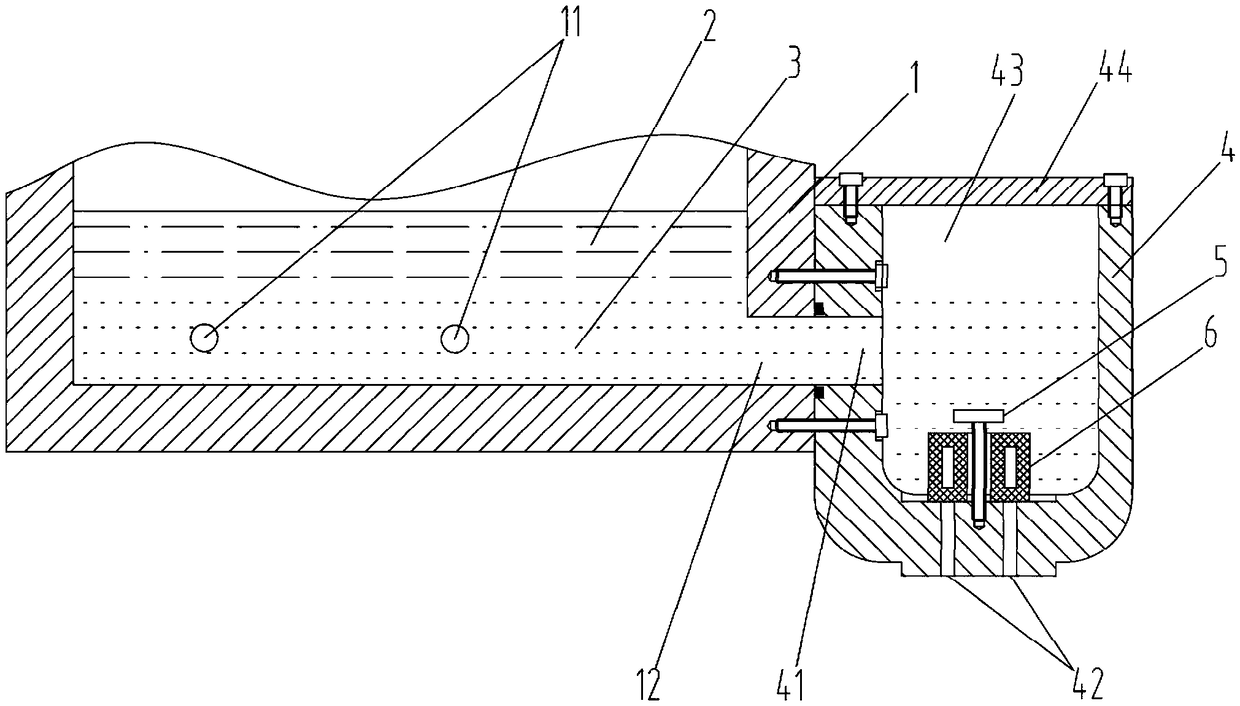

[0018] see figure 1 , the present invention relates to an automatic release device for accumulated water in a vacuum pump oil tank. The vacuum pump oil tank includes an oil tank body 1, and a lubricating oil 2 is arranged in a hollow cavity of the oil tank body 1. Below the lubricating oil 2 is accumulated water 3. An oil return hole 11 and an oil discharge hole 12 are opened on the oil tank body 1 . The feature is: the automatic water release device includes an additional cavity 4, which is arranged beside the fuel tank body 1 and on one side of the oil discharge hole 12, and the addi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com