Method for implementing rapid measurement on content of elements of lanthanum, calcium and cobalt in high-performance magnetic material BMS-12

A technology of BMS-12 and magnetic materials, applied in the direction of measuring devices, analyzing materials, and using wave/particle radiation for material analysis, etc., can solve the complex detection process of iodometric method and atomic absorption spectrometry, the rapid analysis that has never been seen, Can not quickly determine the content and other problems, to achieve the effect of good reproducibility, high accuracy, fast analysis speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the specific content of the present invention. Obviously, the described embodiments are only some of the embodiments of the present invention, not all of them. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention. The content not described in detail in the embodiments of the present invention belongs to the prior art known to those skilled in the art.

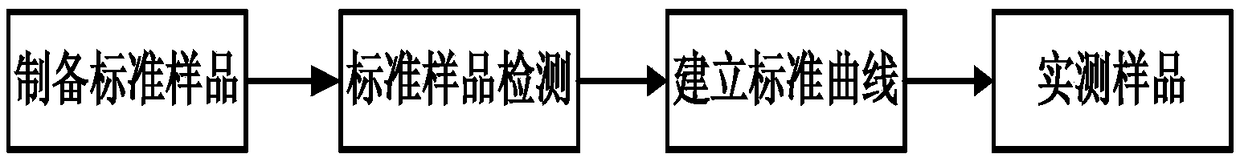

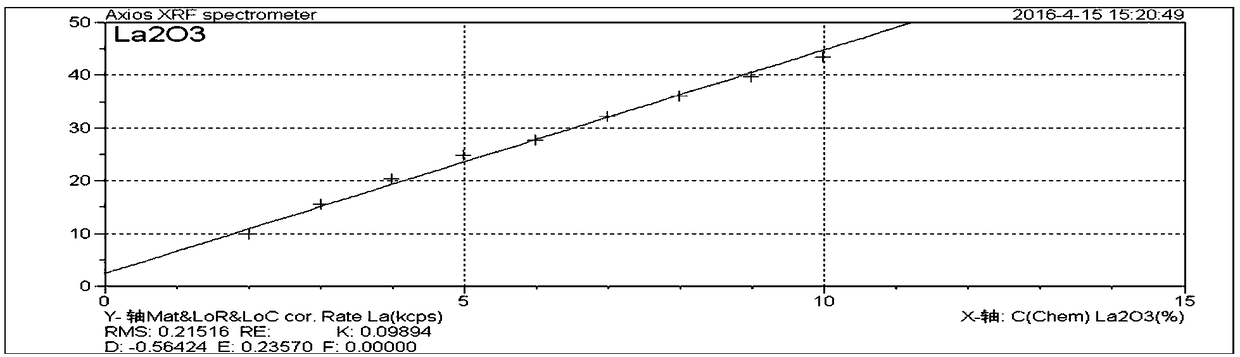

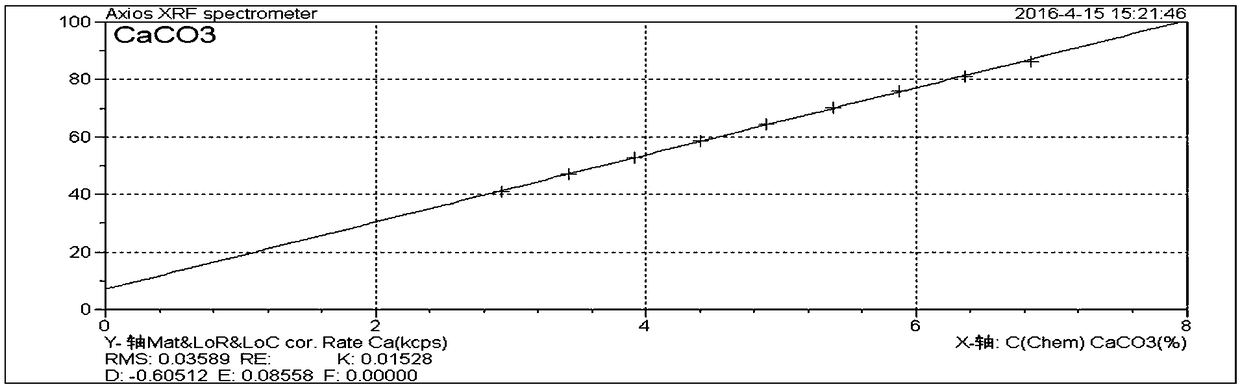

[0020] The embodiment of the present invention provides a method for quickly determining the content of lanthanum, calcium, and cobalt in the high-performance magnetic material BMS-12, which can quickly detect the content of La, Ca, and Co elements in the BMS-12 powder sample, and solve the problem of detecting BMS-12 In the process o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com