Capacitive sensor for measuring phase volume fraction of two-phase flow and optimization method of structural parameters

A technology of capacitive sensors and structural parameters, applied in measurement devices, material capacitances, instruments, etc., can solve the problems of inability to real-time online measurement, high safety requirements, and high sensor cost, and achieve non-contact real-time online measurement and structural parameters. Optimized, easy-to-accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The structure and structure parameter optimization method of the capacitive sensor of the present invention will be described below with reference to the drawings and embodiments.

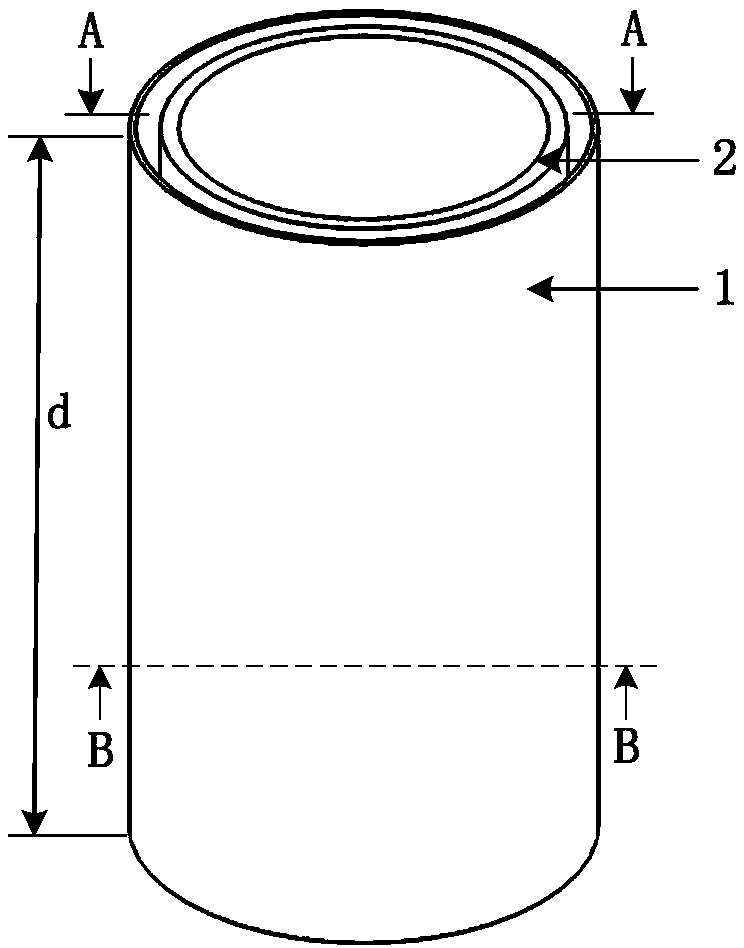

[0038] The capacitive sensor for measuring the phase holdup of two-phase flow provided by the present invention, as shown in Figure 1, includes: a cylindrical pipe section 2, as a part of the pipeline, the sensor is connected in series in the pipeline;

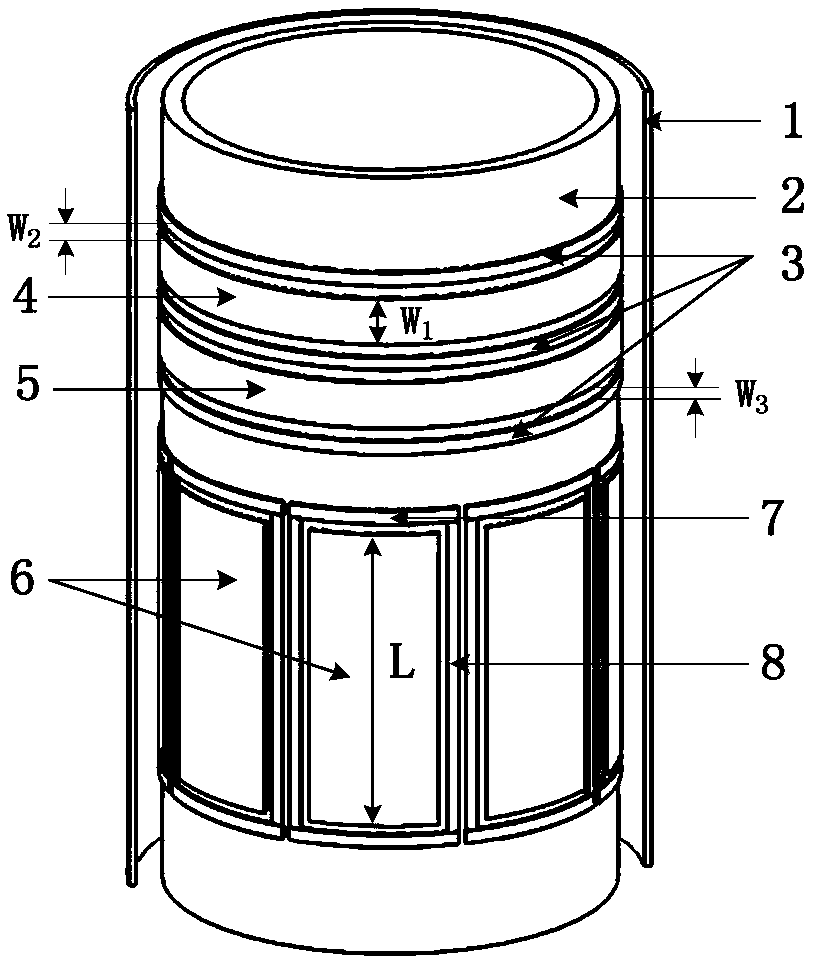

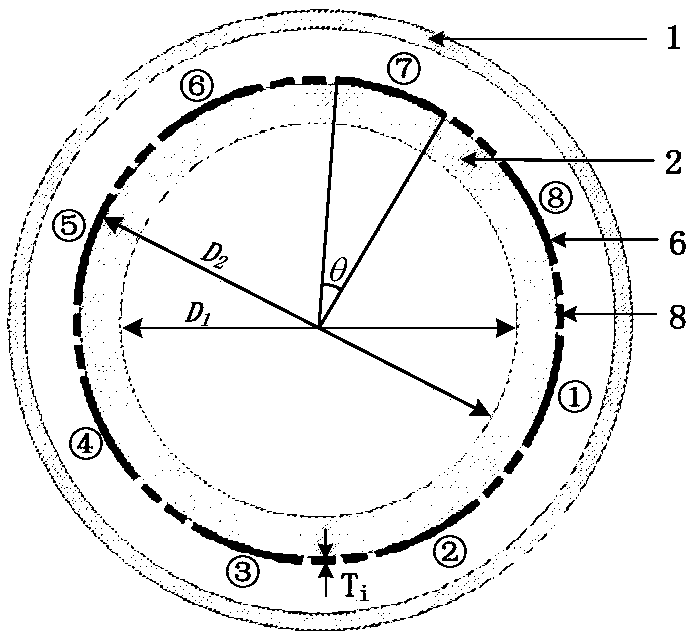

[0039] The upper half of the outer wall of the cylindrical pipe section 2 is affixed with a pair of annular electrodes at intervals, and the annular electrodes include an annular excitation electrode 4 and an annular measuring electrode 5 for measuring the moisture content of the gas-liquid two-phase flow;

[0040] Eight rectangular electrodes 6 are evenly spaced on the lower half of the outer wall of the cylindrical pipe section 2. The length direction of the rectangular electrodes 6 is parallel to the axial direction of the cylindrical pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com