Pantograph carbon contact strip wear recognition method based on improved Canny operator

A pantograph carbon slide and identification method technology, applied in computing, image data processing, instruments, etc., can solve problems such as poor precision and single laser detection function, and achieve the effect of enhancing safety and improving the level of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] In order to illustrate the present invention more clearly, the present invention will be further described below in conjunction with preferred embodiments and accompanying drawings. Similar parts in the figures are denoted by the same reference numerals. Those skilled in the art should understand that the content specifically described below is illustrative rather than restrictive, and should not limit the protection scope of the present invention.

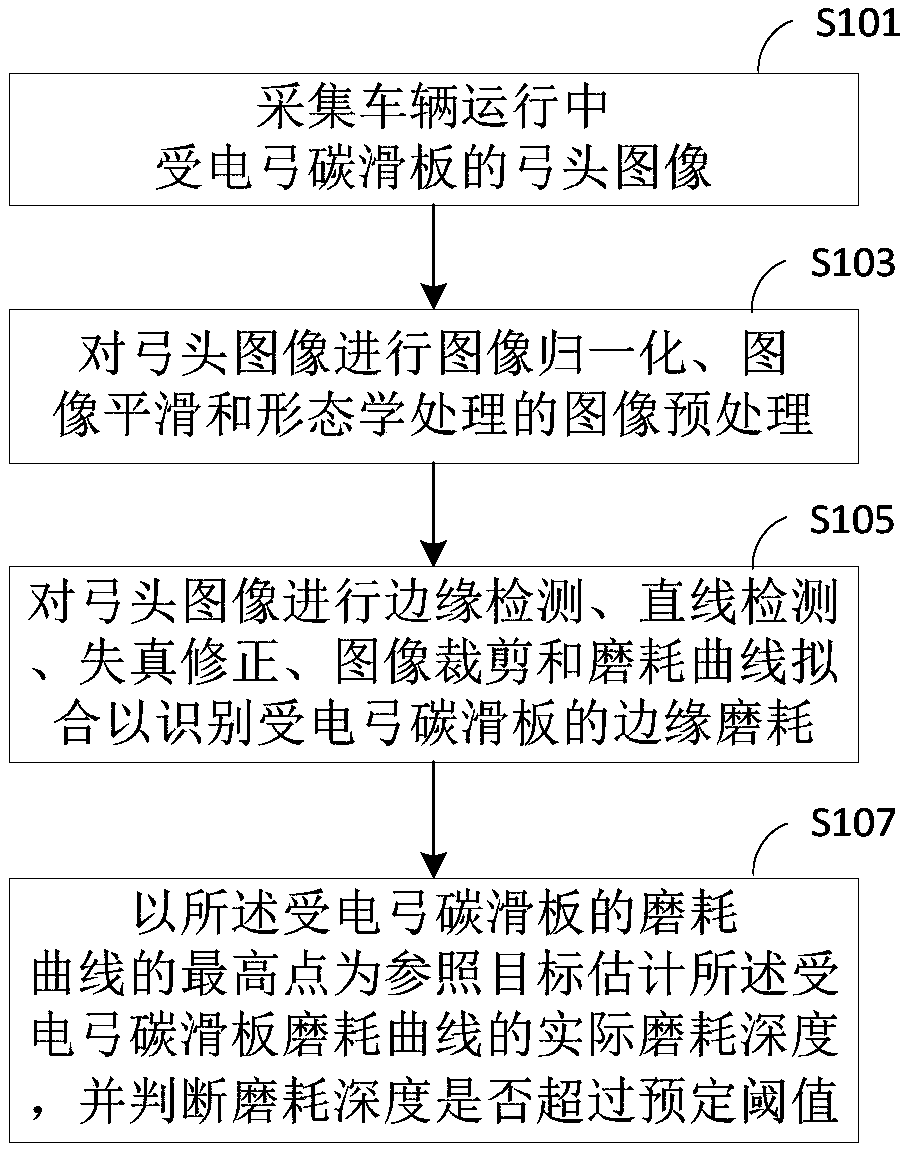

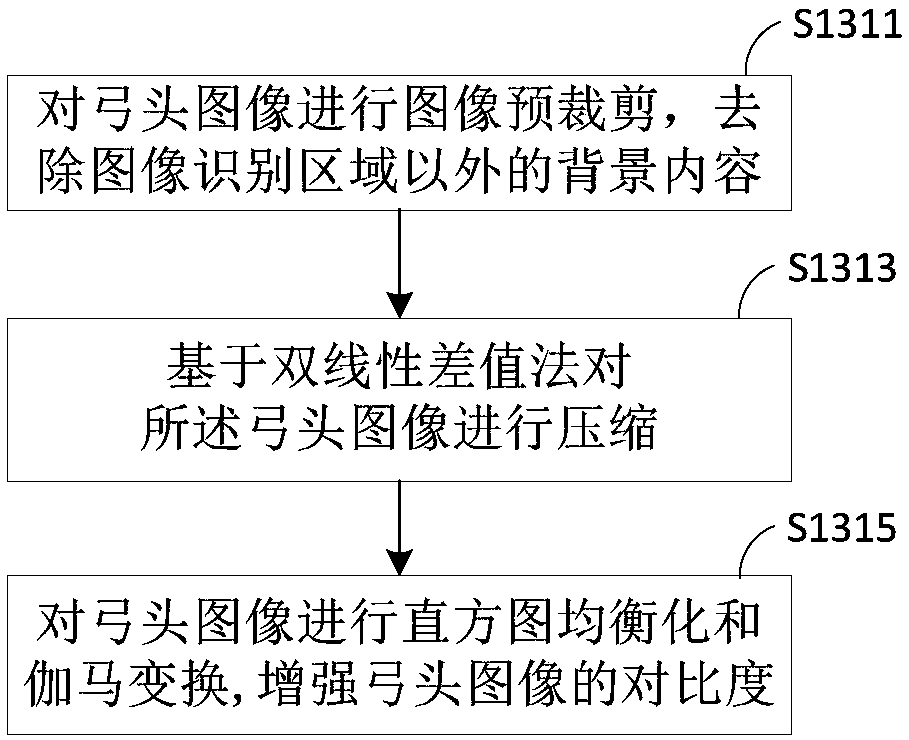

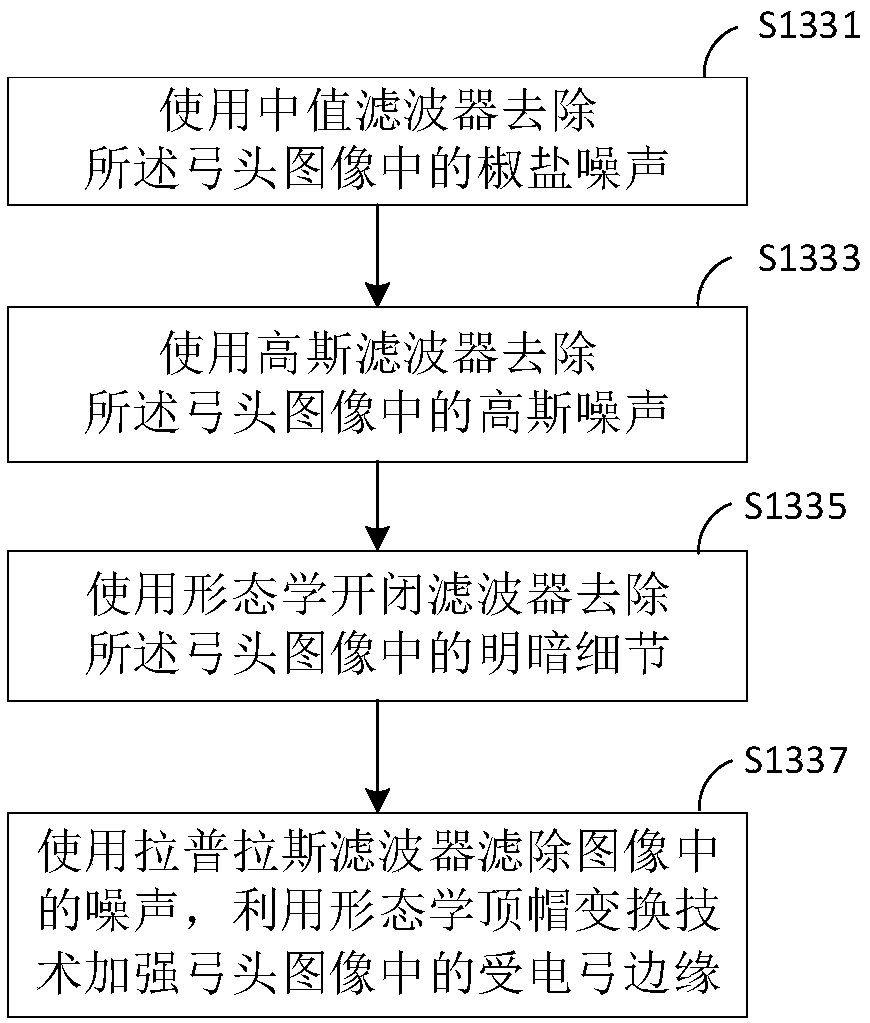

[0056] An embodiment of the present invention provides a method for identifying the wear of a pantograph carbon slide plate based on the improved Canny operator, such as figure 1 shown, including:

[0057]S101: Collect the bow head image of the carbon slide plate of the pantograph when the vehicle is running. The carbon slide plate of the pantograph is assembled on the upper surface of the pantograph head, but due to the limitation of the railway, the image acquisition equipment cannot be installed directly above the pant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com