a light emitting diode

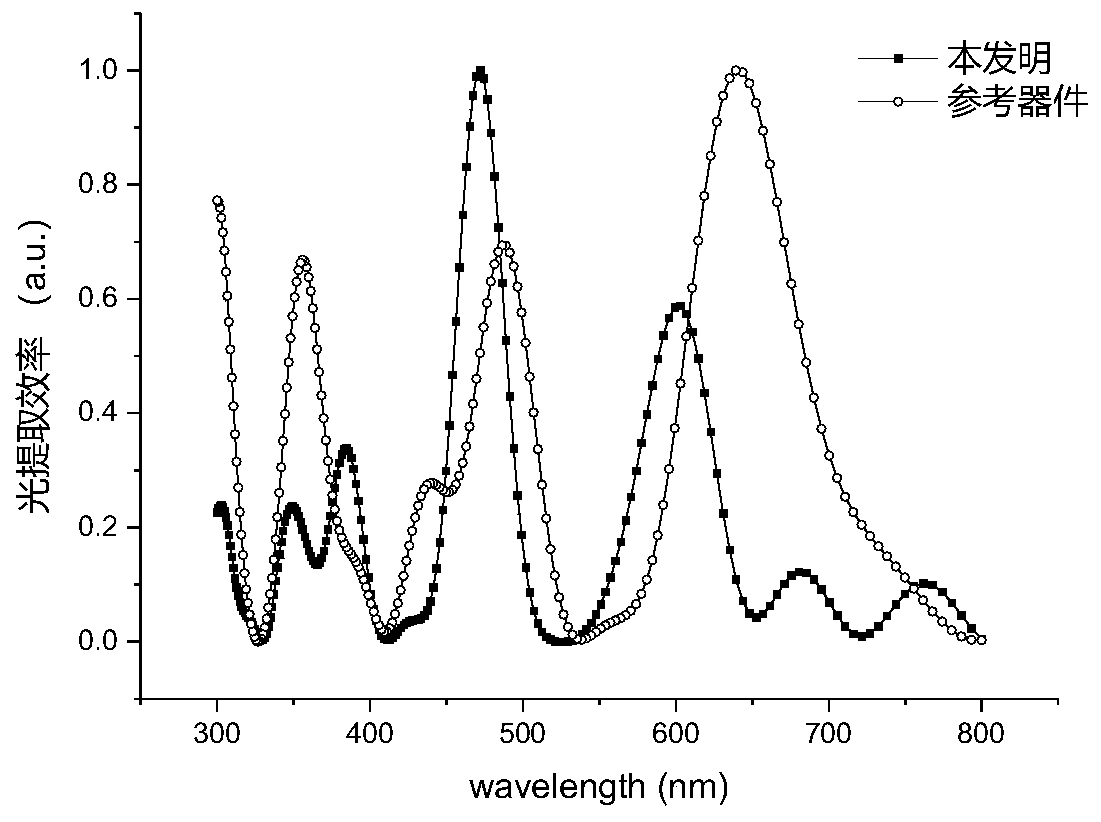

A technology of light-emitting diodes and metal electrodes, applied in nano-optics, nano-technology for materials and surface science, semiconductor devices, etc., can solve problems such as stability, response speed decline, and limit the development of RCLEDs, and achieve significant performance improvements. Enhance the external quantum efficiency of the device and improve the effect of the external quantum efficiency of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

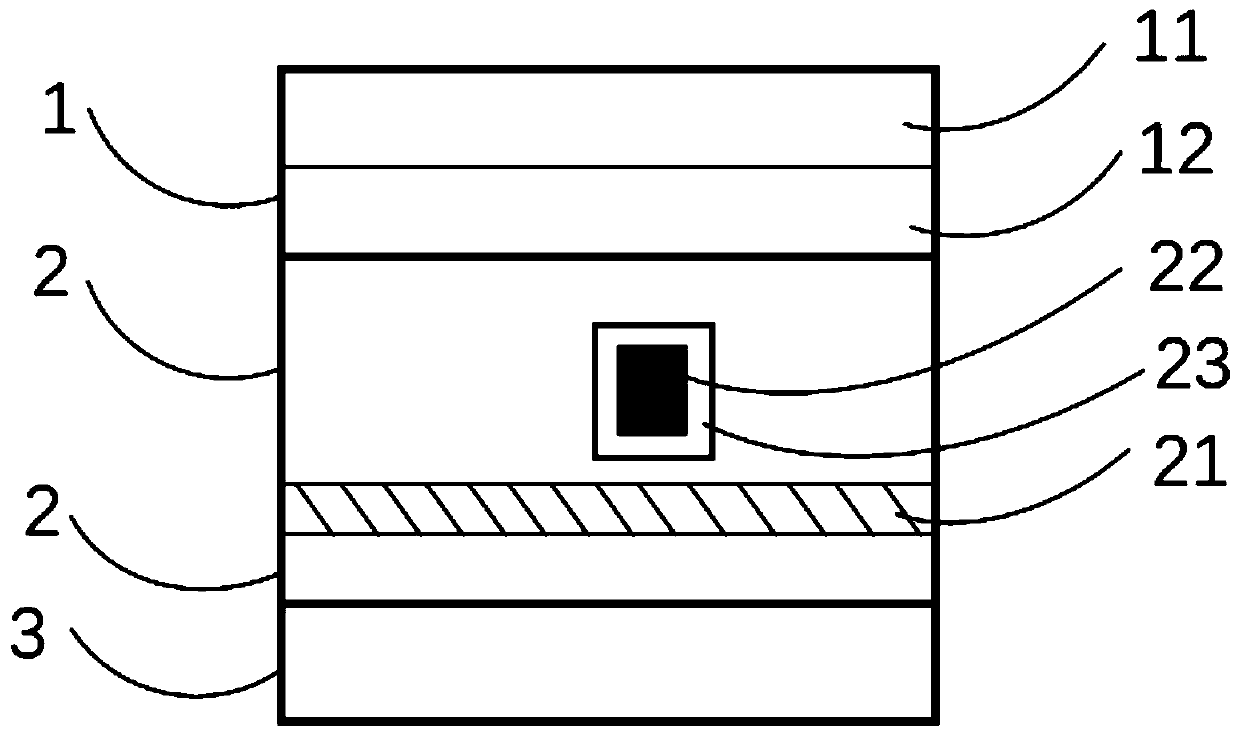

[0035] In this embodiment, the material of the transparent medium layer 11 in the single-period mirror group 1 used is SiO 2 , the refractive index of the transparent medium layer 11 is 1.4, and the thickness is 78nm.

[0036] In this embodiment, the material of the metal nano-thin layer 12 in the single-period mirror group 1 is silver, and the thickness of the metal nano-thin layer 12 is 25 nm.

[0037] In this embodiment, the thickness of the active region 2 used is 480 nm, and the refractive index of the active region 2 is 2.3.

[0038] In this embodiment, the metal electrode 3 is made of aluminum with a thickness of 200 nm.

[0039] In this embodiment, the material of the metal nanoparticles 22 used is silver, the shape of which is cubic, and the side length of the cube is 34 nm. The distance between the upper surface of the nanocube and the lower surface of the metal nano-thin layer 12 of the single-period mirror group 1 is 72 nm. The distance between the lower surface...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com