Captive directional feeding structure for lambs

A technology for sheep pens and feeding troughs, applied in animal feeding devices, applications, animal husbandry, etc., can solve the problems of limited nutritional value and single feed for young sheep, achieve reasonable design and layout, prevent partial eclipse for young sheep, and simple and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

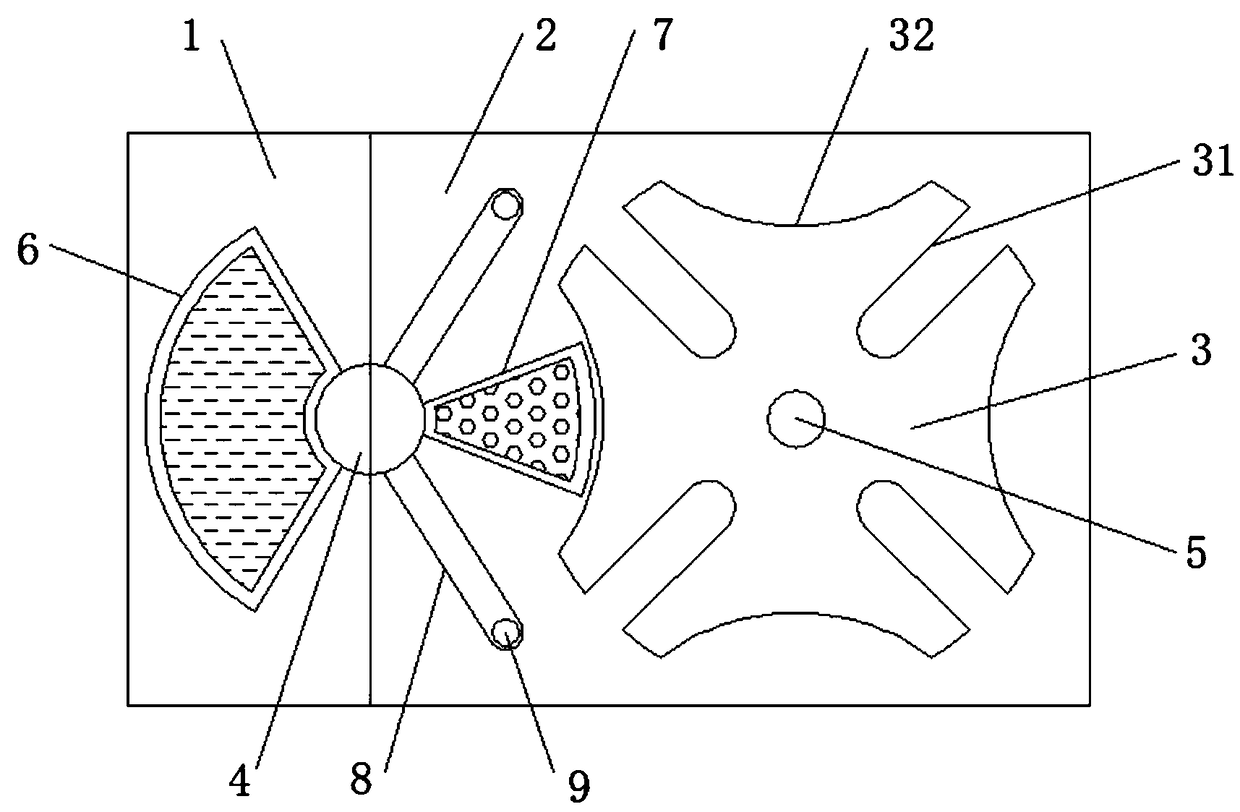

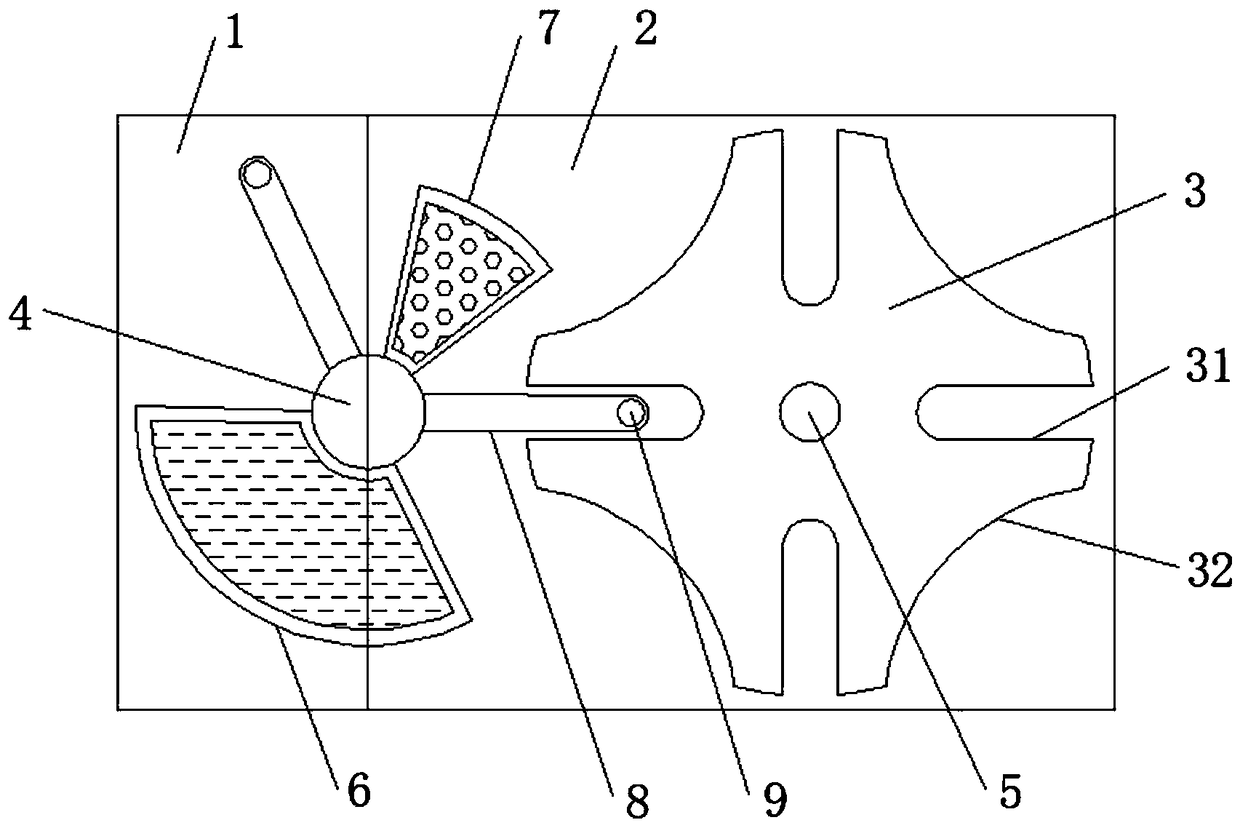

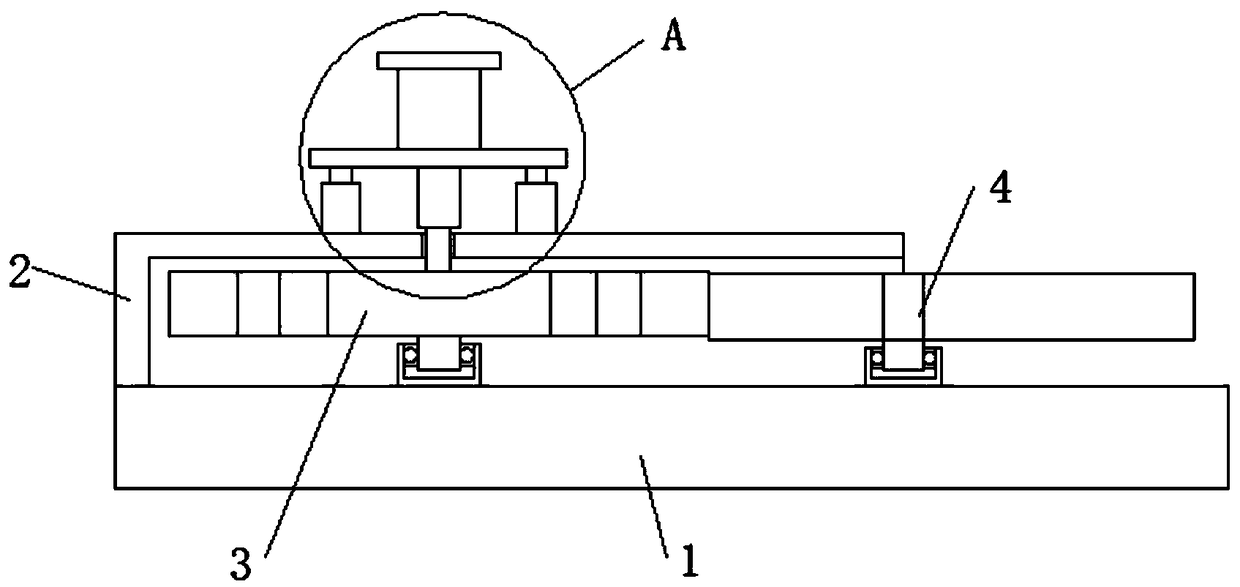

[0026] Embodiment 1, with reference to Figure 1-4 , a directional feeding structure for young sheep in captivity, comprising a base 1, a closed frame 2 is installed on the top side of the base 1, and an active plate 3 and a driven rod 4 arranged side by side are mounted on the inner rotation of the closed frame 2, wherein the active plate The periphery of 3 is provided with a plurality of power square grooves 31 and arc-shaped chutes 32, and the power square grooves 31 and arc-shaped chutes 32 are arranged in a staggered manner, and the outer wall of the driven rod 4 is welded with rows along the diameter direction of the driven rod 4. The liquid feeding trough 6, the solid feeding trough 7 and the driving long rod 8 of the cloth, the end of the driving long rod 8 away from the driven rod 4 is welded with a guide block 9, and the guide block 9 matches the power square groove 31, and the liquid feeding trough 6 All match with arc-shaped chute 32 with solid feeding groove 7, an...

Embodiment 2

[0032] Embodiment 2, with reference to Figure 1-6, a directional feeding structure for young sheep in captivity, comprising a base 1, a closed frame 2 is installed on the top side of the base 1, and an active plate 3 and a driven rod 4 arranged side by side are mounted on the inner rotation of the closed frame 2, wherein the active plate The periphery of 3 is provided with a plurality of power square grooves 31 and arc-shaped chutes 32, and the power square grooves 31 and arc-shaped chutes 32 are arranged in a staggered manner, and the outer wall of the driven rod 4 is welded with rows along the diameter direction of the driven rod 4. The liquid feeding trough 6, the solid feeding trough 7 and the driving long rod 8 of the cloth, the end of the driving long rod 8 away from the driven rod 4 is welded with a guide block 9, and the guide block 9 matches the power square groove 31, and the liquid feeding trough 6 All match with arc-shaped chute 32 with solid feeding groove 7, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com