White tea processing technology

A processing technology, white tea technology, applied in the direction of tea treatment before extraction, etc., can solve problems such as unfavorable for consumers to travel, weakening of white tea market competitive advantage, increase in storage and transportation costs, shorten heating time, expand consumer market, Improving the effect of bulky appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

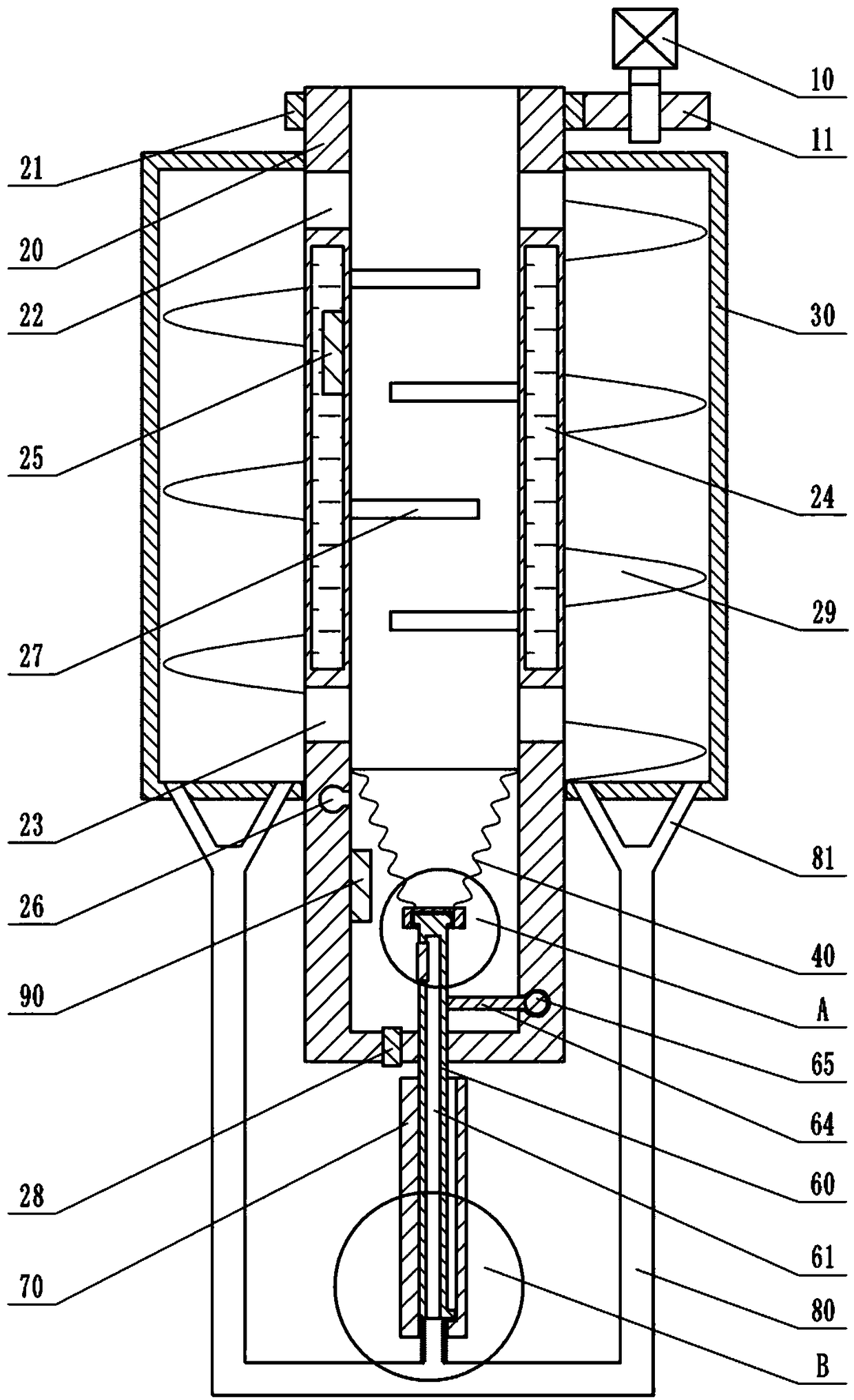

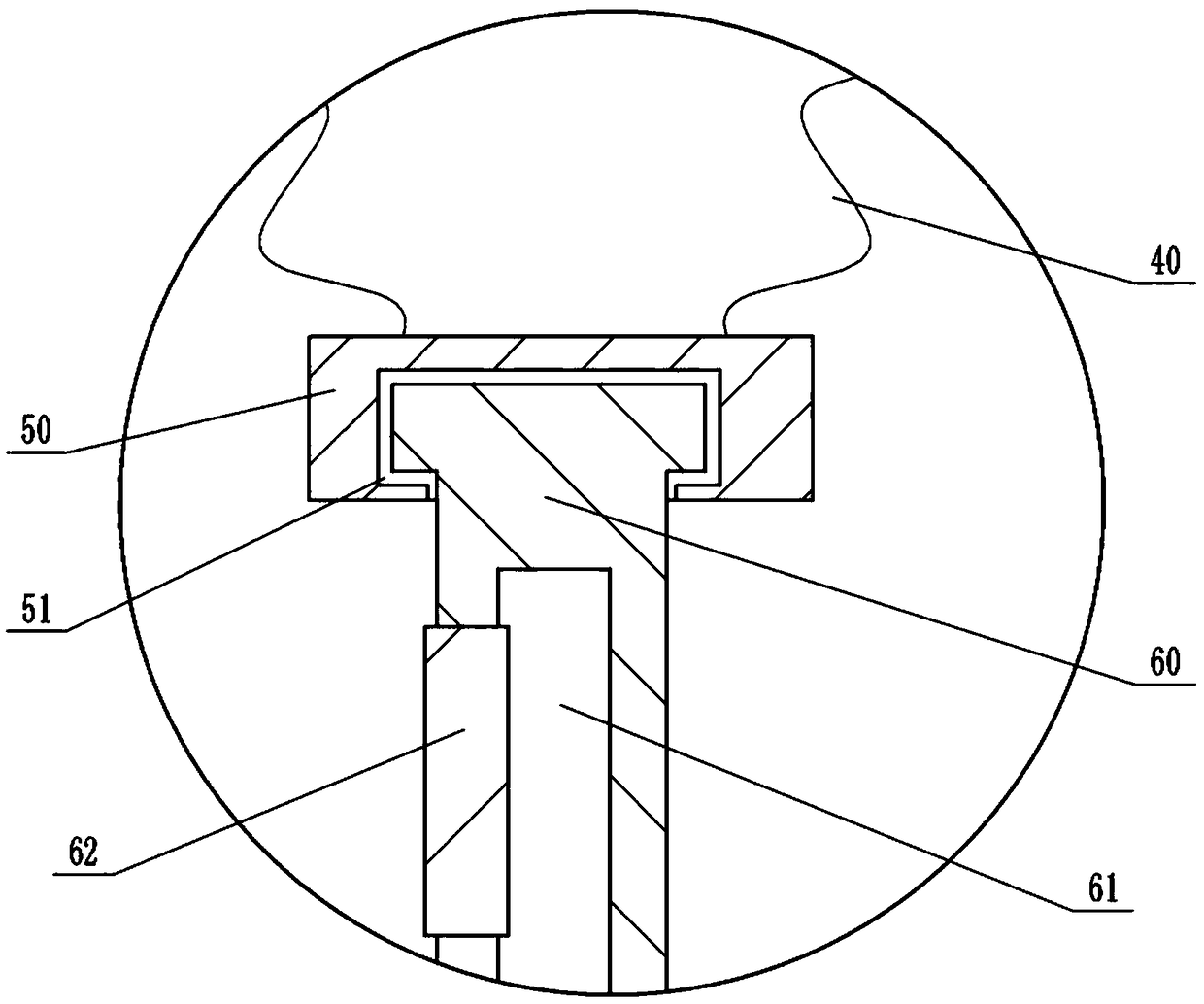

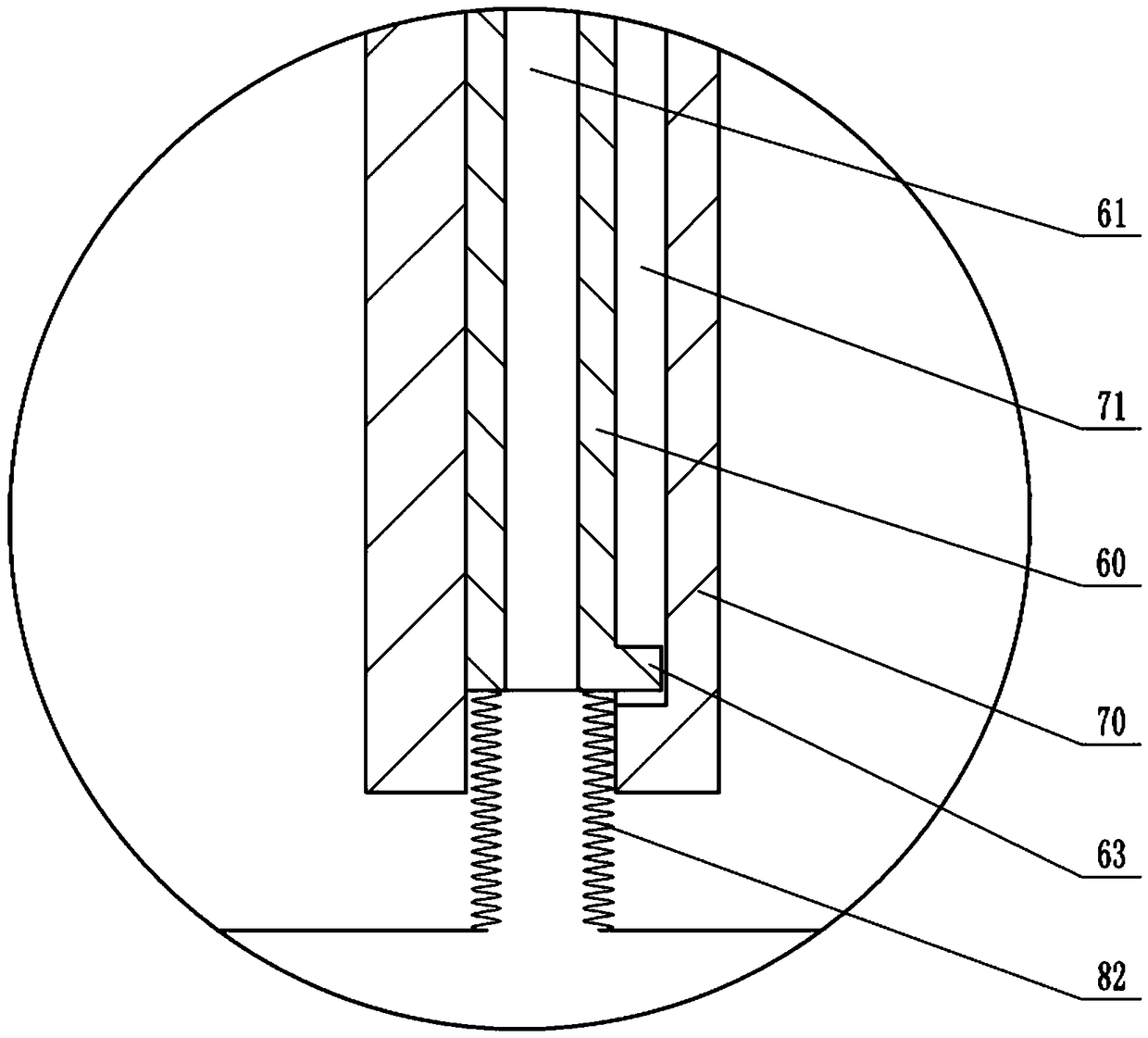

Image

Examples

Embodiment 1

[0025] This embodiment discloses a white tea processing technology, comprising the following processing steps:

[0026] 1) Picking: pick fresh leaves with one bud and one leaf at the beginning, the buds and leaves form flowers, the size is uniform, the stalk should be short, pick lightly.

[0027] 2) Screening: screening the tea leaves after picking, separating the impurities in the tea leaves, and selecting tea leaves that meet the processing standards.

[0028] 3) Withering: spread out the tea leaves, control the thickness at 1.5 cm, control the withering water loss rate at 35%; control the withering temperature at 24° C., and control the relative humidity at 69%.

[0029] 4) Kneading: Prepare a sponge ball with a diameter of 0.4cm, and embed quartz with a particle size of 0.2cm in the sponge ball; heat the sponge ball to a temperature of 60°C; combine the heated sponge ball with the step (3) ) the tea leaves obtained after the treatment are put into a kneading machine, and...

Embodiment 2

[0037] This embodiment discloses a white tea processing technology, comprising the following processing steps:

[0038] 1) Picking: pick fresh leaves with one bud and one leaf at the beginning, the buds and leaves form flowers, the size is uniform, the stalk should be short, pick lightly.

[0039] 2) Screening: screening the tea leaves after picking, separating the impurities in the tea leaves, and selecting tea leaves that meet the processing standards.

[0040] 3) Withering: spread the tea leaves, control the thickness at 1.6 cm, control the withering water loss rate at 38%; control the withering temperature at 25° C., and control the relative humidity at 70%.

[0041] 4) Finishing: use a liquefied gas drum fixing machine for finishing, preheat the cylinder to 150°C, and control the amount of leaves in each pot at 1.8kg, and let it cool in time after it is out of the pot.

[0042] 5) Kneading: Prepare a sponge ball with a diameter of 0.5 cm, and embed quartz with a particle...

Embodiment 3

[0045] This embodiment discloses a white tea processing technology, comprising the following processing steps:

[0046] 1) Picking: pick fresh leaves with one bud and one leaf at the beginning, the buds and leaves form flowers, the size is uniform, the stalk should be short, pick lightly.

[0047] 2) Screening: screening the tea leaves after picking, separating the impurities in the tea leaves, and selecting tea leaves that meet the processing standards.

[0048] 3) Withering: spread the tea leaves, control the thickness at 1.5cm, control the withering water loss rate at 38%; control the withering temperature at 23° C., and control the relative humidity at 72%.

[0049] 4) Finishing: use a liquefied gas drum fixing machine for finishing, preheat the cylinder to 165°C, and control the amount of leaves in each pot at 1.8kg, and spread it to cool in time after it is out of the pot.

[0050] 5) Kneading: Prepare a sponge ball with a diameter of 0.45cm, and embed quartz with a par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com