Grinding device for wooden door plate

A technology for sheet materials and wooden doors, which is applied in the field of grinding devices for wooden door sheets, can solve problems such as large dust and affect health, and achieve the effect of preventing surface scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

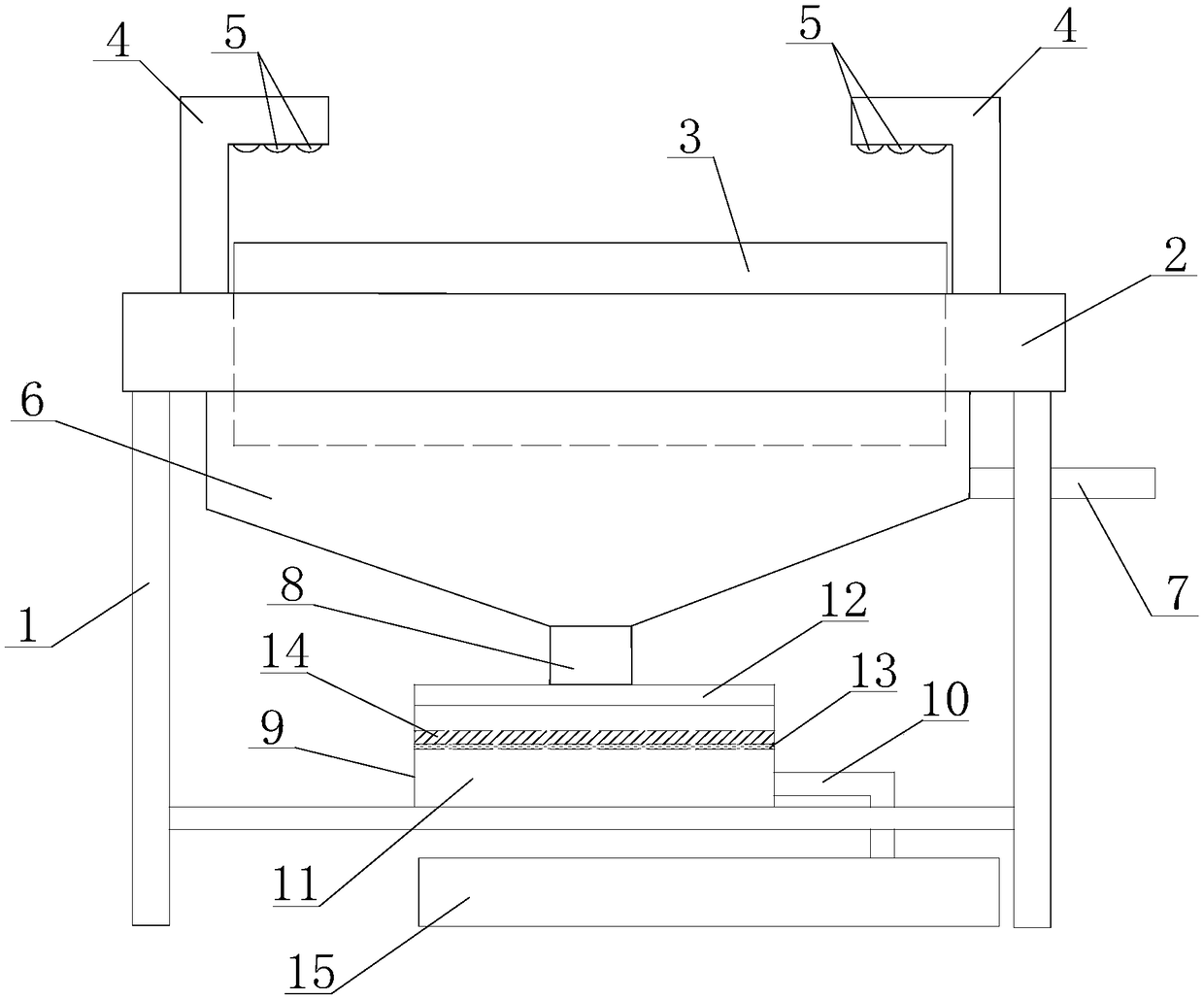

[0022] Such as figure 1 As shown, a polishing device for wood door panels in this embodiment includes a support 1 and a workbench 2. The workbench 2 is arranged on the support 1, and the upper surface of the workbench 2 is recessed to form a through hole. A plurality of grinding rollers 3 parallel to each other are arranged in the through hole. The grinding rollers 3 extend from the upper surface and the lower surface of the worktable 2, and further include a pair of L-shaped limit plates 4, the pair of L-shaped limit plates The plate 4 is arranged on the upper surface of the worktable 2 and is located on both sides of the through hole, the part of the L-shaped limiting plate 4 is located above the grinding roller 3, and the L-shaped limiting plate 4 is provided with balls 5, so The ball 5 is located above the sanding roller 3; the lower surface of the workbench 2 is provided with a dust hood 6, the upper end of the dust hood 6 communicates with the through hole, and the side w...

Embodiment 2

[0025] On the basis of Example 1, such as figure 1 As shown, the top of the box body 11 is provided with a detachable cover 12, the cover 12 is provided with an inlet, the water outlet pipe 8 is a corrugated hose, and the water outlet pipe 8 is connected to the cover 12 through the inlet. It is convenient to observe the situation inside the box by removing the lid. It is convenient to clean up the impurities deposited in the box.

Embodiment 3

[0027] On the basis of Example 1, such as figure 1 As shown, a limiting member 13 is provided on the inner wall of the box body 11, the limiting member 13 is provided above the outlet, and a filter screen 14 is provided on the limiting member 13. The filter screen is set up to limit the impurities above the outlet, avoiding excessive impurities from blocking the outlet provided on the side of the box body and causing water to be unable to drain from the box body.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com