Automatic dust removing device for textile fabrics

A technology for automatic dust removal and textile fabrics, which is applied in the field of textile machinery and can solve the problems of being easily contaminated with a large amount of dust and flocs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below by means of specific embodiments:

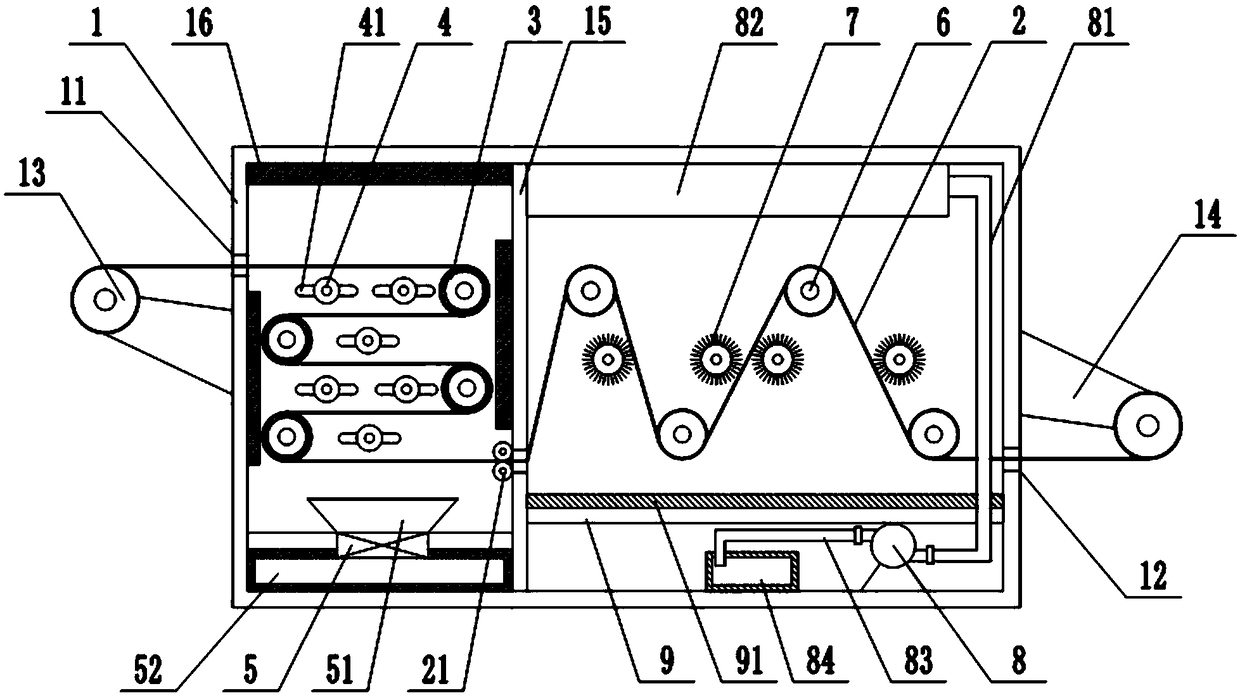

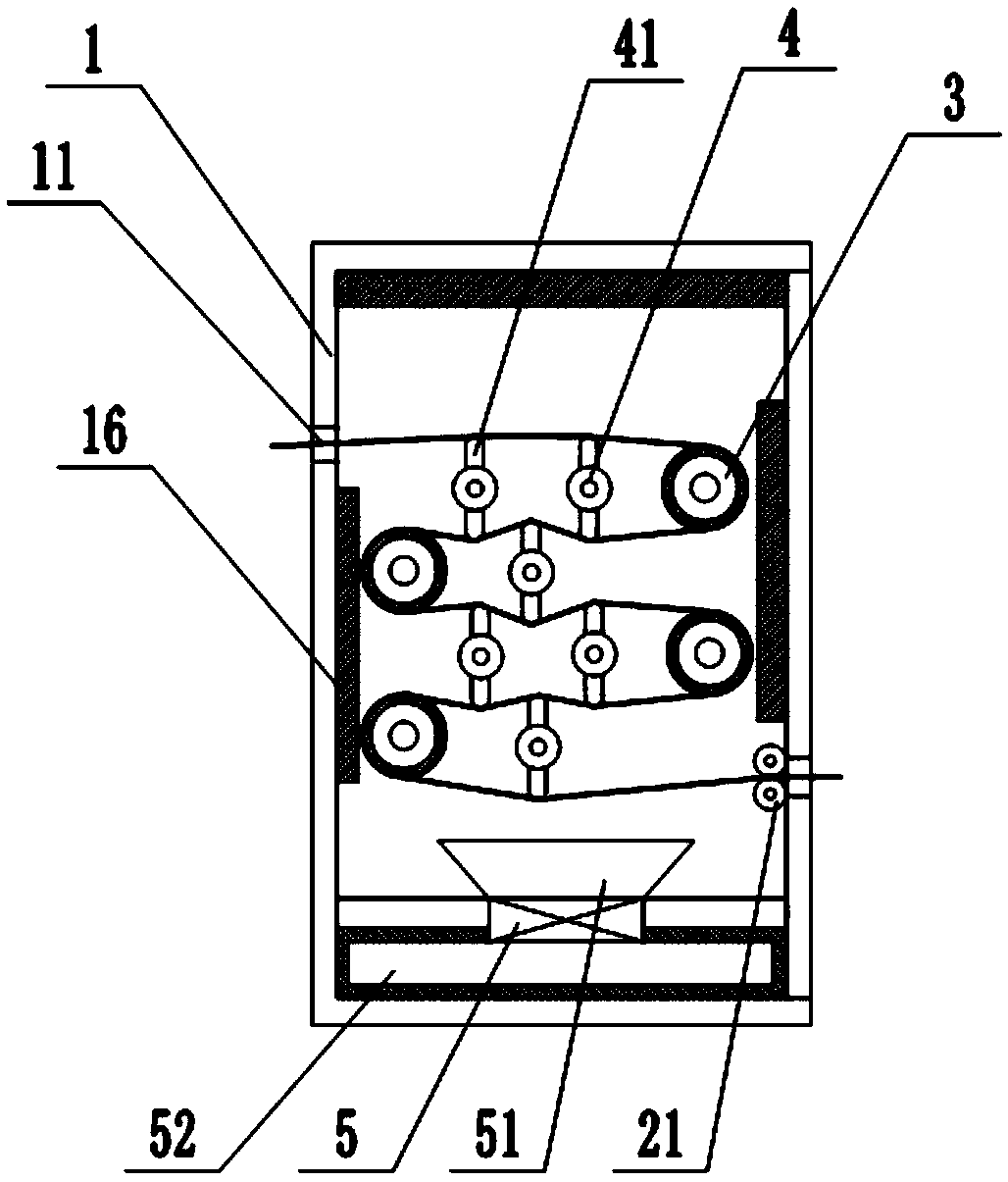

[0016] The reference signs in the drawings of the description include: box body 1, fabric inlet 11, fabric outlet 12, fabric unwinding mechanism 13, fabric rewinding mechanism 14, partition 15, heating lamp 16, fabric 2, fabric clamping roller group 21. The first cloth conveying roller 3, the cloth supporting roller 4, the columnar protrusion 41, the first fan 5, the first dust cover 51, the collection box 52, the second cloth conveying roller 6, the brush roller 7, the second fan 8. Dust suction pipe 81, second dust suction cover 82, air outlet pipe 83, dust collection box 84, horizontal plate 9, electrostatic plate 91.

[0017] The embodiment is basically as attached Figures 1 to 2 Shown: an automatic dust removal device for textile cloth, including a box body 1, a cloth inlet 11 and a cloth outlet 12 are respectively provided on both sides of the box body 1, and a cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com