Crankshaft, compressor and refrigeration equipment

A technology of refrigeration equipment and compressors, which is applied in the field of compressors, can solve the problems of large processing loss, low reliability, and difficult standardization of crankshaft parts, and achieve the effects of reducing processing and manufacturing costs, high reliability, and realizing standardization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

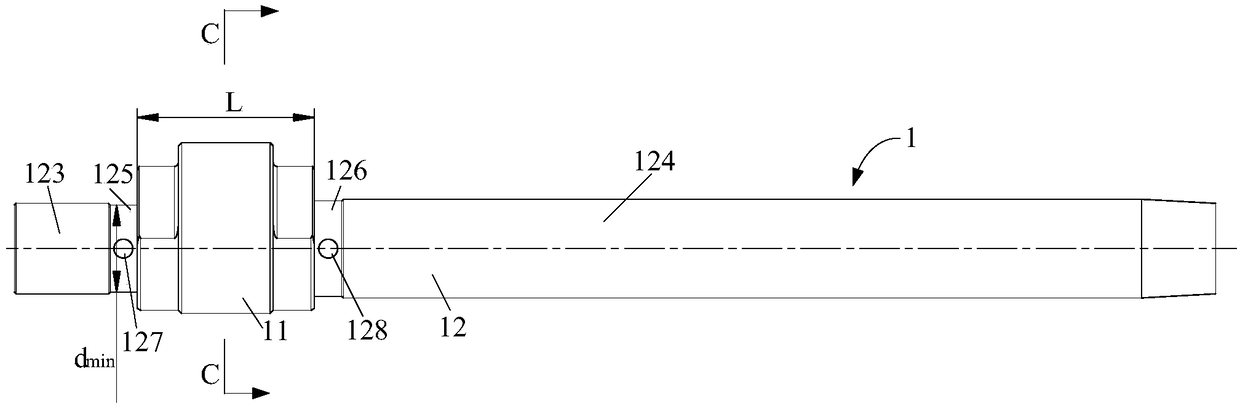

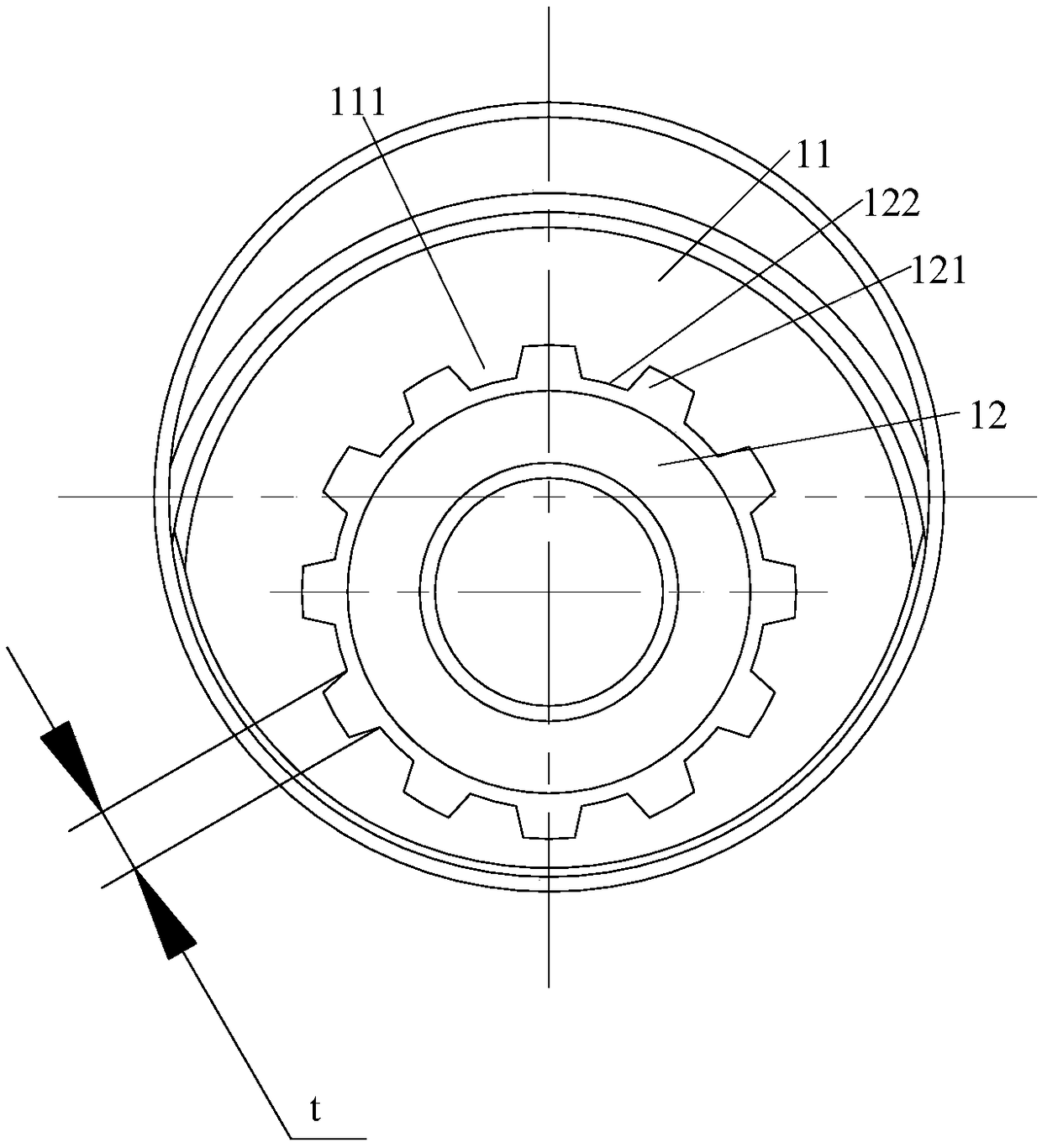

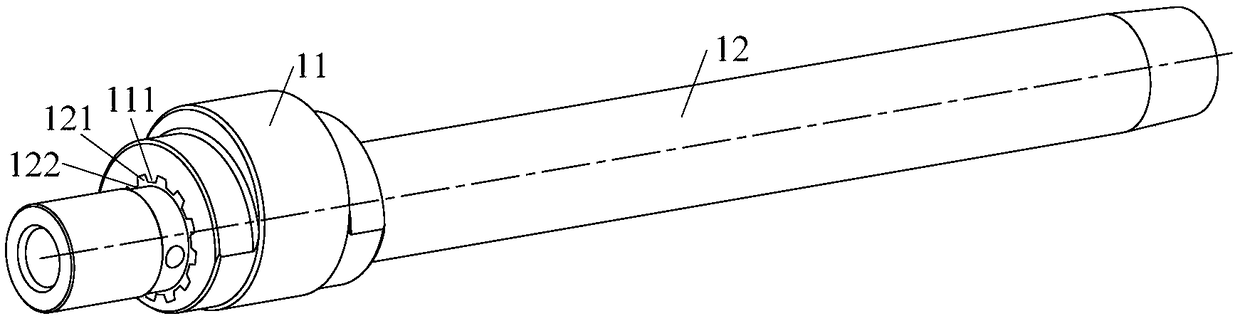

[0057] like Figure 1 to Figure 5 As shown, a crankshaft according to this embodiment includes a linear shaft 12 and an eccentric portion 11 . The eccentric part 11 is provided with a rough mounting hole 112, which is eccentrically arranged with the outer diameter of the eccentric part 11, and is provided with protrusions 111 along the axial direction, and the protrusions 111 are evenly distributed along the circumference of the mounting hole 112, and the number is n. A part of the linear shaft 12 is set in the installation hole 112, and the outer wall surface of the part where the linear shaft 12 cooperates with the eccentric part 11 is provided with a protruding structure 121, and the groove 122 and the protrusion 111 formed between the protruding structures 121 Fitted with each other to form a form-fit in the circumferential direction. A concave position is formed between two adjacent protrusions, and the protruding structure is located in the concave position.

[0058] ...

Embodiment 2

[0066] like Figure 6 As shown, a crankshaft according to Embodiment 2 is substantially the same as Embodiment 1. The difference is that the cross-sectional profile of the protrusion 111 and the protruding structure 121 in this embodiment is roughly in the shape of an involute gear tooth, that is, the cross-section of the protrusion 111 and the protruding structure 121 contains at least one circle involute.

[0067] According to the crankshaft of this embodiment, the protrusion 111 and the protrusion structure 121 can use existing gear design and processing methods, thereby reducing development and manufacturing costs.

Embodiment 3

[0069] like Figure 7 As shown, a crankshaft according to Embodiment 3 is substantially the same as Embodiment 1. The difference is that the cross-sections of the protrusion 111 and the protruding structure 121 in this embodiment include at least one arc.

[0070] According to the crankshaft of this embodiment, the protrusion and the protruding structure have a larger cross-sectional area and are easy to process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com